304 4x8 Stainless Steel Sheet Metal Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t

- Supply Capability:

- 25000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

304 4x8 Stainless Steel Sheet Metal Price

1.Product Description

1. Specifications about stainless steel sheet

Commodity430 304 304L 316L 201 316 4x8 sheet metal prices stainless steel

Grade201,202,304,304L,316,316L,310S,309S,321,301,310,410,420,430,904L

BrandTISCO ,BAOSTEEL,POSCO,JISCO,LISCO

CertificationSGS,BV,IQI,TUV,ISO,etc

Thickness0.2mm-150mm

Width1000,1219,1250,1500mm, or as your requirements

Length2000,2438,2500,3000,6000mm, or as your requirements

SurfaceNo.1, 2B, BA, 8K Mirror, Hairline,satin, Embossed,brush,No.4,HL,matt,pvc film,laser film.

StandardASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc

Delivery time5-7 days after confirming the order

MOQ1 Ton

AdvantagesShowing the splendor of your quality, wearresistant as well , strong corrosion resistance and decorative effect, durable and beautiful in good taste.

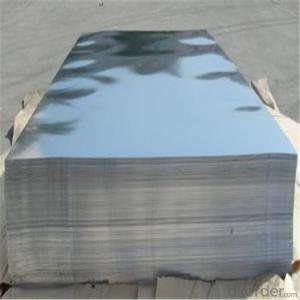

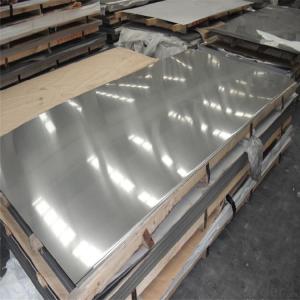

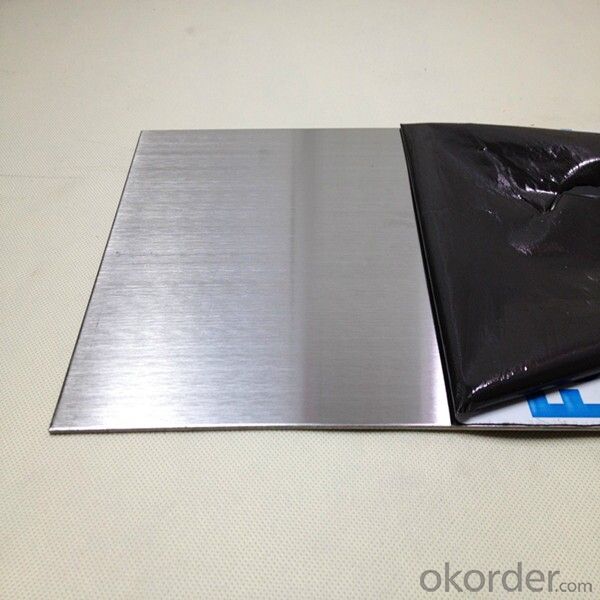

2.Products photos

3.FAQ

1.Small quantity, short time delivery

If we have stocks, the delivery time is less than 7 days,If the quantity is more than 500Tons,the delivery time is abou 30 days after confirming the order.

2.Choose the appropriate metals stainless steel for your needs.

We carefully balance quality, delivery time and price,procure various grades metals from all over the world.

3.Lower total cost

We taking your processing into account,offer you reduce a total cost by using our product.

We assure you:

Small MOQ + Cheap Price + Fantastic Quality + Fast Delivery

- Q: Can stainless steel sheets be used for power generation equipment?

- Stainless steel sheets are indeed applicable for power generation equipment. With its versatility, stainless steel possesses a range of advantageous qualities specifically tailored for power generation applications. Its corrosion resistance is exceptional, a paramount characteristic for equipment that comes into contact with water, steam, or other corrosive substances. Moreover, stainless steel exhibits remarkable strength and durability, enabling it to withstand the elevated temperatures and pressures frequently encountered in power generation systems. Another notable attribute is its proficiency as an electrical conductor, rendering it suitable for electrical components and connections within the equipment. Consequently, stainless steel sheets are widely employed in the construction of power generation equipment, including turbines, boilers, heat exchangers, and exhaust systems.

- Q: Can stainless steel sheets be used for decorative panels?

- Yes, stainless steel sheets can definitely be used for decorative panels. Stainless steel is known for its durability, strength, and resistance to corrosion, making it an excellent choice for decorative purposes. It is widely used in interior design, architecture, and various industries for its aesthetic appeal. Stainless steel sheets can be customized with different finishes, such as brushed, polished, or patterned, to create unique and visually appealing decorative panels. Additionally, stainless steel sheets can be easily cut, shaped, and formed into various designs, making them versatile for different decorative applications. Whether it is for wall cladding, elevator interiors, furniture accents, or signage, stainless steel sheets offer a modern, sleek, and sophisticated look that enhances the overall aesthetics of any space.

- Q: How do you prevent intergranular corrosion on stainless steel sheets?

- Intergranular corrosion on stainless steel sheets can be prevented by using low carbon grades of stainless steel, such as the 304L or 316L alloys, which have reduced carbon content. Additionally, heat treatment processes like solution annealing can help eliminate carbide precipitation and reduce the susceptibility to intergranular corrosion. Finally, avoiding exposure to corrosive environments and implementing proper cleaning and maintenance practices can further minimize the risk of intergranular corrosion on stainless steel sheets.

- Q: What are the different surface finishes available for stainless steel sheets?

- There are several different surface finishes available for stainless steel sheets, each offering unique characteristics and aesthetics. 1. No.1 Finish: This is the most common and widely used finish for stainless steel sheets. It has a rough, dull appearance with visible grain lines. No.1 finish is obtained by hot rolling the stainless steel and is suitable for applications where a rough finish is acceptable. 2. No.2B Finish: This finish is obtained by cold rolling the stainless steel and then annealing it, resulting in a smooth, reflective surface with a slightly dull appearance. It is commonly used for kitchen appliances, architectural accents, and decorative purposes. 3. No.2D Finish: Similar to No.2B finish, No.2D finish is achieved by cold rolling and annealing the stainless steel. However, it has a smoother and shinier appearance, making it suitable for applications requiring a more polished look. 4. No.3 Finish: Also known as a brushed finish, No.3 finish is achieved by polishing the stainless steel with abrasive belts or brushes. It has a unidirectional satin-like appearance, often used for decorative purposes in architecture and interior design. 5. No.4 Finish: This finish is obtained by polishing the stainless steel with finer abrasive belts or brushes than No.3 finish. It has a more refined and smoother appearance, often used for decorative purposes, such as elevator panels, kitchen equipment, and automotive trim. 6. No.8 Finish: Also known as a mirror finish, No.8 finish is achieved by polishing the stainless steel with progressively finer abrasive materials until a highly reflective surface is obtained. It provides a glossy, mirror-like appearance, ideal for architectural and decorative applications. 7. Hairline Finish: Hairline finish is achieved by mechanically polishing the stainless steel surface with a fine abrasive material. It creates a subtle, linear pattern with a matte appearance, commonly used for architectural accents, appliances, and decorative items. These are some of the most common surface finishes available for stainless steel sheets. The choice of finish depends on the desired aesthetics, functionality, and application requirements.

- Q: Can stainless steel sheets be used for elevator mirrors or panels?

- Stainless steel sheets are indeed suitable for elevator mirrors or panels. Elevator interiors often opt for stainless steel due to its enduring quality, stylish look, and ability to resist corrosion and scratches. By utilizing stainless steel sheets, elevator mirrors or panels achieve a contemporary and sophisticated appearance, while also ensuring effortless cleanliness and upkeep. Moreover, stainless steel is a versatile material that can be personalized with diverse finishes like polished, brushed, or textured, amplifying the allure of the elevator interior.

- Q: Are stainless steel sheets suitable for food storage containers?

- Yes, stainless steel sheets are suitable for food storage containers. Stainless steel is a popular choice for food storage containers due to its many beneficial properties. Firstly, stainless steel is non-reactive, meaning it does not interact with or leach any harmful chemicals into the food, ensuring that the taste and quality of the food is preserved. Additionally, stainless steel is resistant to corrosion, rust, and staining, making it a durable and long-lasting material for food storage containers. It is also easy to clean and maintain, as it does not absorb odors or flavors from previous food items. Furthermore, stainless steel is a hygienic material, as it does not harbor bacteria or other pathogens, ensuring that your food remains safe and healthy. Overall, stainless steel sheets are an excellent choice for food storage containers due to their suitability for contact with food, durability, and hygienic properties.

- Q: How can I classify stainless steel plates?

- The stainless steel plate in accordance with the classification of surface features can be divided into: silver white matte (use does not need to have a surface gloss), bright as a mirror (building materials, kitchen utensils), coarse grinding fine grinding / polishing / intermediate / fine grinding (building materials, kitchen utensils), hairline grinding (buildings, building materials), close to the mirror grinding (art, decoration), mirror grinding (mirror, decorative).

- Q: How do you remove scratches from mirror-finish stainless steel sheets?

- To remove scratches from mirror-finish stainless steel sheets, you can follow these steps: 1. Clean the surface of the stainless steel sheet with a mild detergent and warm water, then dry it thoroughly. 2. Identify the direction of the grain on the stainless steel sheet. The grain usually runs in one direction and appears as faint lines. 3. Using a non-abrasive stainless steel cleaner or a mixture of baking soda and water, gently rub the scratched area along the grain with a soft cloth or sponge. 4. Continue rubbing in a consistent motion until the scratches start to fade. Avoid applying excessive pressure to prevent further damage. 5. Rinse the surface with clean water and wipe it dry with a soft cloth. 6. If the scratches are still visible, you can try using a stainless steel scratch remover or a metal polish specifically designed for stainless steel. Follow the product instructions and apply it to the scratched area following the grain. 7. Once the scratches are no longer visible, clean the surface again with mild detergent and water, then dry it thoroughly to restore the mirror-finish appearance.

- Q: Can stainless steel sheets be used for medical instrument trays?

- Yes, stainless steel sheets can be used for medical instrument trays. Stainless steel is a common material used in medical settings due to its durability, resistance to corrosion, and ease of cleaning. It is suitable for maintaining a sterile environment and can withstand repeated sterilization processes without degrading.

- Q: How do you prevent galling when using stainless steel sheets?

- To prevent galling when using stainless steel sheets, there are several measures you can take: 1. Lubrication: Apply an appropriate lubricant or anti-seize compound on the contact surfaces to reduce friction. This helps to create a barrier between the stainless steel sheets and prevent them from sticking and galling. 2. Proper surface finish: Ensure that the stainless steel sheets have a smooth surface finish. Rough or uneven surfaces can increase the risk of galling. Consider using sheets with a polished or finely ground finish to minimize the chance of galling. 3. Control the contact pressure: Avoid excessive pressure when using stainless steel sheets. Excessive pressure can generate heat and increase friction, leading to galling. Adjust the pressure to a level that allows smooth movement without causing excessive friction. 4. Minimize sliding or rubbing: Reduce the amount of sliding or rubbing between stainless steel sheets. If possible, use rolling or lifting techniques instead of dragging or sliding the sheets across each other. This helps to minimize the risk of galling by reducing the contact area and friction. 5. Use compatible materials: When using stainless steel sheets in contact with other materials, ensure they are compatible. Some materials, such as aluminum or certain coatings, can promote galling when in contact with stainless steel. Choose materials that are less prone to galling or use protective coatings to prevent direct contact. 6. Avoid excessive heat: Excessive heat can increase the likelihood of galling in stainless steel sheets. Ensure that the temperature is controlled and does not reach levels that can cause the sheets to heat up significantly. This can be achieved through proper cooling methods or by using heat-resistant materials if necessary. By following these preventive measures, you can significantly reduce the risk of galling when using stainless steel sheets, ensuring smooth operation and prolonging the lifespan of the sheets.

Send your message to us

304 4x8 Stainless Steel Sheet Metal Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t

- Supply Capability:

- 25000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords