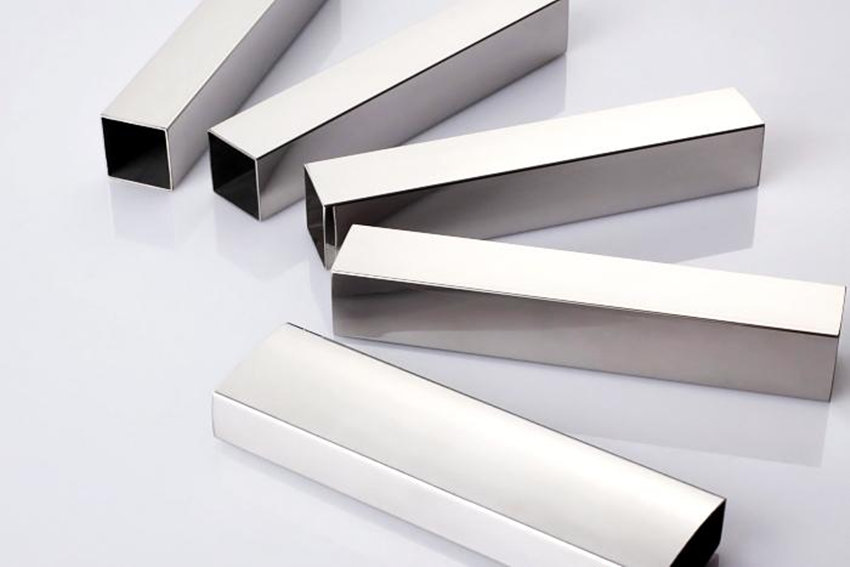

316Ti Welded Stainless Steel Tubing

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Welded Pipe

APPLICATION:

Industrial Fluid Conveying

Boiler,Heat Exchanger and condenser

Sanitary and Thin-wall water pipe

Oil and Gas transportation etc.

Standards :

ASTM A249/A269/A270/A312/A358/A788/A789/A790

DIN/EN 10217/DIN 11850

JIS G3459,GB/T 12771 etc.

SIZES:

|

OUTSIDE DIAMETER |

OD |

WALL THICKNESS | |||

|

SCH 5S |

SCH 10S |

SCH 40S | |||

|

N.B |

NPS |

mm |

mm |

mm |

mm |

|

8 |

1/4' |

13.72 |

- |

- |

2.24 |

|

10 |

3/8' |

17.15 |

- |

- |

2.31 |

|

15 |

1/2' |

21.34 |

1.65 |

2.11 |

2.77 |

|

20 |

3/4' |

26.67 |

1.65 |

2.11 |

2.87 |

|

25 |

1' |

33.4 |

1.65 |

2.77 |

3.38 |

|

32 |

1-1/4' |

42.16 |

1.65 |

2.77 |

3.56 |

|

40 |

1-1/2' |

48.26 |

1.65 |

2.77 |

3.68 |

|

50 |

2' |

60.33 |

1.65 |

2.77 |

3.91 |

|

65 |

2-1/2' |

73.03 |

2.11 |

3.05 |

5.16 |

|

80 |

3' |

88.9 |

2.11 |

3.05 |

5.49 |

|

90 |

3-1/2' |

101.6 |

2.11 |

3.05 |

5.74 |

|

100 |

4' |

114.3 |

2.11 |

3.05 |

6.02 |

|

125 |

5' |

141.3 |

2.77 |

3.4 |

6.55 |

|

150 |

6' |

168.28 |

2.77 |

3.4 |

7.11 |

|

200 |

8' |

219.08 |

2.77 |

3.76 |

8.18 |

|

250 |

10' |

273.05 |

3.4 |

4.19 |

9.27 |

|

300 |

12' |

323.85 |

3.96 |

4.57 |

9.52 |

|

350 |

14' |

355.6 |

3.96 |

4.78 |

11.13 |

|

400 |

16' |

406.4 |

4.19 |

4.78 |

12.7 |

|

450 |

18' |

457.2 |

4.19 |

4.78 |

14.27 |

|

500 |

20' |

508 |

4.78 |

5.54 |

15.09 |

|

550 |

22' |

558.8 |

4.78 |

5.54 |

15.09 |

|

600 |

24' |

609.6 |

5.54 |

6.35 |

17.48 |

|

650 |

26' |

660.4 |

5.54 |

7.92 |

17.48 |

|

700 |

28' |

711.2 |

5.54 |

7.92 |

17.48 |

|

750 |

30' |

762 |

6.35 |

7.92 |

17.48 |

|

800 |

32' |

812.8 |

- |

7.9 |

17.48 |

|

850 |

34 |

863.6 |

- |

7.92 |

17.48 |

|

900 |

36' |

914.4 |

- |

7.92 |

19.05 |

|

1000 |

40' |

1016 |

- |

9.53 |

- |

- Q: Are stainless steel sheets suitable for outdoor signage?

- Yes, stainless steel sheets are suitable for outdoor signage. Stainless steel is a popular choice for outdoor applications due to its durability, corrosion resistance, and aesthetic appeal. It is highly resistant to rust and can withstand harsh weather conditions, making it ideal for outdoor signage that needs to withstand exposure to rain, sunlight, and extreme temperatures. Additionally, stainless steel sheets can be easily customized and fabricated to create various designs and shapes, making it a versatile material for outdoor signage. Its sleek and polished finish also adds a professional and modern look to any signage. Overall, stainless steel sheets are a reliable and long-lasting option for outdoor signage.

- Q: Are stainless steel sheets resistant to fire?

- Yes, stainless steel sheets are highly resistant to fire. Due to their high melting point and excellent heat resistance, stainless steel sheets do not easily ignite or contribute to the spread of fire, making them ideal for applications where fire safety is crucial.

- Q: What are the main chemical constituents of stainless steel plates?

- Stainless steel is often divided into martensitic steel, ferritic steel, austenitic steel, austenitic ferrite (duplex) stainless steel and precipitation hardening stainless steel according to the state of the organization. In addition, can be divided into components: chromium stainless steel, chromium nickel stainless steel and chromium, manganese, nitrogen, stainless steel and so on.

- Q: What is the formability of stainless steel sheets?

- The formability of stainless steel sheets refers to their ability to be shaped or formed into desired geometries without cracking, tearing, or losing their structural integrity. Stainless steel sheets are known for their excellent formability due to their unique combination of strength, ductility, and corrosion resistance. They can be easily bent, rolled, or stretched into various shapes, making them versatile for a wide range of applications. Additionally, stainless steel sheets can maintain their form even under extreme temperatures or harsh environments, further enhancing their formability. However, it is important to note that the formability of stainless steel sheets can vary depending on the specific grade, thickness, and surface finish. Higher grades of stainless steel tend to have better formability, while thicker sheets may require more force to shape. Surface finish, such as cold-rolled or hot-rolled, can also affect formability as it can influence the material's grain structure and mechanical properties. Therefore, understanding the specific characteristics and limitations of the stainless steel sheet being used is crucial in determining its formability for a particular application.

- Q: Are stainless steel sheets suitable for automotive grilles or trim?

- Automotive grilles or trim can be effectively improved by using stainless steel sheets. This material is highly durable and resistant to corrosion, making it suitable for withstanding the challenging conditions found in the automotive environment. These conditions include exposure to moisture, road salt, and fluctuating temperatures. Stainless steel is also renowned for its strength, providing excellent protection to the front end of vehicles. What's more, stainless steel sheets can be easily shaped and molded into different designs and forms to meet the specific style requirements of automotive grilles or trim. Additionally, stainless steel possesses an attractive aesthetic appeal that can enhance the overall appearance of the vehicle. In summary, the utilization of stainless steel sheets for automotive grilles or trim guarantees long-lasting durability, functionality, and a refined look.

- Q: How do you join stainless steel sheets together?

- Stainless steel sheets can be joined together through various methods, such as welding, riveting, bolting, or using adhesives. The specific joining technique depends on the application, the desired strength, and the aesthetic requirements.

- Q: What are the different types of stainless steel sheets available?

- There are several different types of stainless steel sheets available in the market, each with its own unique properties and applications. Some of the most common types include: 1. Austenitic Stainless Steel Sheets: This type of stainless steel is the most widely used and offers excellent corrosion resistance, high strength, and good formability. It is commonly used in kitchen equipment, food processing plants, and pharmaceutical industries. 2. Ferritic Stainless Steel Sheets: Ferritic stainless steel sheets have a higher chromium content and lower carbon content compared to austenitic stainless steel. They are known for their excellent resistance to stress corrosion cracking and are often used in automotive applications, architectural structures, and appliances. 3. Martensitic Stainless Steel Sheets: Martensitic stainless steel sheets have a higher carbon content compared to other types, which gives them high strength and hardness. They are commonly used in applications requiring wear resistance, such as cutlery, surgical instruments, and turbine blades. 4. Duplex Stainless Steel Sheets: Duplex stainless steel sheets have a mixed microstructure of austenite and ferrite, which provides them with a combination of high strength and excellent corrosion resistance. They are often used in chemical processing plants, oil and gas industries, and marine environments. 5. Precipitation Hardening Stainless Steel Sheets: Precipitation hardening stainless steel sheets are heat-treatable and offer high strength and corrosion resistance. They are commonly used in aerospace applications, defense equipment, and high-performance industries. It's important to consider the specific requirements of your project or application when choosing the type of stainless steel sheet, as each type has its own set of properties and advantages.

- Q: Are stainless steel sheets scratch-resistant?

- Stainless steel sheets, in general, have the ability to resist scratches. The durability and scratch-resistant nature of stainless steel make it a suitable material for different uses, such as kitchen appliances, countertops, and decorations. Nevertheless, it is crucial to bear in mind that even though stainless steel exhibits high resistance against scratches, it is not entirely impervious to them. The surface of stainless steel sheets can still be scratched or marked if sharp objects or abrasive materials are used, particularly with excessive force or repeated contact. By regularly maintaining and properly caring for stainless steel sheets, the visibility of scratches can be minimized, ensuring they remain in their best condition.

- Q: What is the maximum length of a stainless steel sheet?

- The maximum length of a stainless steel sheet can vary depending on several factors, including the manufacturing capabilities, supplier limitations, and transportation constraints. In general, stainless steel sheets can be produced in lengths ranging from a few feet to several hundred feet. However, it is important to note that longer lengths may be more difficult to handle and transport, which could impact availability and cost. Additionally, custom orders or specialized applications may allow for even longer stainless steel sheets. Therefore, it is best to consult with manufacturers or suppliers to determine the specific maximum length options available for stainless steel sheets.

- Q: Are stainless steel sheets good for chemical processing?

- Stainless steel sheets are renowned for their exceptional performance in chemical processing. Their remarkable resistance to corrosion and chemical damage has made them highly sought-after across various industries, particularly in chemical processing. The abundant presence of chromium and nickel in stainless steel imparts it with an extraordinary ability to withstand chemical reactions, even when exposed to harsh chemicals and acids. Furthermore, stainless steel sheets offer hassle-free cleaning, maintenance, and sterilization, which are crucial factors in chemical processing environments where cleanliness and hygiene are of utmost importance. The durability and strength of stainless steel sheets also guarantee their longevity and capacity to endure extreme temperatures and pressures, rendering them suitable for a wide array of chemical processing applications. All in all, stainless steel sheets emerge as a dependable and efficient choice for chemical processing due to their corrosion resistance, ease of maintenance, and enduring nature.

1. Manufacturer Overview

| Location | Anhui,China |

| Year Established | 2003 |

| Annual Output Value | Above US$16 Million |

| Main Markets | South Korea;Japan; Europe;ASEAN;India |

| Company Certifications | ISO 9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 70% |

| No.of Employees in Trade Department | 160 People |

| Language Spoken: | English;Chinese;Japanese;Korea |

| b) Factory Information | |

| Factory Size: | Above 300,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

316Ti Welded Stainless Steel Tubing

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords