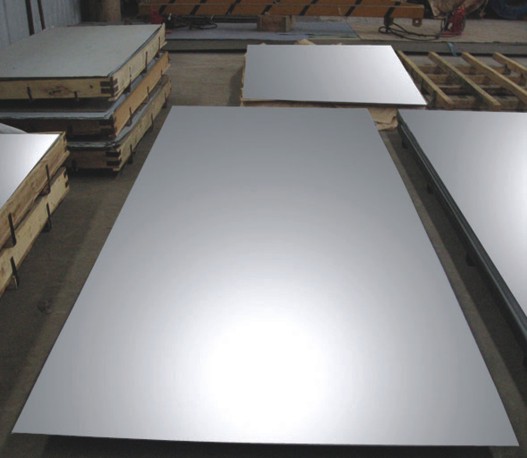

Stainless Steel Sheet 4K Surface Treatment 0.9mmx1220mmx2440mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction ofStainless Steel Sheet 4K Surface Treatment 0.9mmx1220mmx2440mm:

Our Stainless Steel products including the stainless steel sheet/plate, stainless steel coil, stainless steel rod/bar, stainless steel angle, stainless steel strip, stainless steel flat, carbon steel products and alloy steel materials. It also can supply the processing of surface, like No.4, BA, HL, SB, 8K, and so on.

Loading Quantity of Stainless Steel Sheet 4K Surface Treatment 0.9mmx1220mmx2440mm:

25 Tons/20FCL.

Grade of Stainless Steel Sheet 4K Surface Treatment 0.9mmx1220mmx2440mm:

201, 306, 316 Etc.

Delivery Time of Stainless Steel Sheet 4K Surface Treatment 0.9mmx1220mmx2440mm:

20 days Per Container.

Application of Stainless Steel Sheet 4K Surface Treatment 0.9mmx1220mmx2440mm:

| Finish | Thickness | Characteristics | Applications |

| No. 1 | 3.0mm~50.0mm | Finished by hot-rolling, annealing and pickling, characterized by white pickled surface | Chemical industry equipment, Industrial tanks |

| No. 2B | 0.3mm~6.0mm | Finished by heat treatment, pickling after cold rolling, followed by skin pass line to be more brighter and smooth surface | General Application Medical Instruments,Tableware |

| No. BA (Bright Annealed) | 0.5mm~2.0mm | Bright heat treatment after cold rolling | Kitchen utensil, kitchen ware,architectural purpose |

| No. 4 | 0.4mm~3.0mm | Polishing with No. 150 to No.180 mesh abrasivesThe most popular finishes | Milk & Food processing acilities, Hospital Equipment, Bath-tub |

| HL(Hair Line) | 0.4mm~3.0mm | Finished by continuous linear polishing | Architectural purposes, escalators, kitchen ware vehicles |

FAQ

Q: CAN YOU PROVIDE MILL TEST CERTIFICATE?

A: YES! Mill Test Certificate for Stainless Steel Sheet 4K Surface Treatment 0.9mmx1220mmx2440mm are available.

Q: CAN YOU MAKE DDQ (DEEP DRAWING QUALITY)?

A: YES. Our material has been widely used for producing Stainless Steel Pots and Stainless Steel Sinks, which have strict request for good deep drawing quality.

Q: HOW TO GET A SAMPLE?

A: FREE samples for Stainless Steel Sheet 4K Surface Treatment 0.9mmx1220mmx2440mm are available for your checking and testing. And to get free samples, you need to send us you detailed receiving address (including post code) and your DHL/FedEx/UPS account for collecting samples, courier cost will be paid in your side.

- Q: How do you prevent crevice corrosion in stainless steel sheets?

- To prevent crevice corrosion in stainless steel sheets, there are a few key measures that can be taken: 1. Proper design and fabrication: Ensure that the stainless steel sheets are designed and fabricated with smooth surfaces and minimal crevices. This will reduce the potential for stagnant solution entrapment and minimize the risk of crevice corrosion. 2. Regular cleaning and maintenance: Regularly clean the stainless steel sheets to remove any debris or contaminants that can promote crevice corrosion. This can be done using mild detergents or specialized stainless steel cleaners. 3. Avoid exposure to corrosive environments: Limit the exposure of stainless steel sheets to corrosive environments, such as those containing chloride ions (e.g., saltwater). If exposure is unavoidable, consider applying protective coatings or using higher-grade stainless steel alloys that are more resistant to crevice corrosion. 4. Control the environment: Maintain proper environmental conditions, such as controlling temperature, humidity, and pH levels, to minimize the risk of crevice corrosion. Monitoring and controlling these factors can help create a less conducive environment for corrosion to occur. 5. Regular inspections and maintenance: Conduct regular inspections to identify any signs of crevice corrosion, such as discoloration, pitting, or rough surfaces. If any corrosion is detected, take immediate action to remove it and repair the affected area. By implementing these preventive measures, you can significantly reduce the risk of crevice corrosion in stainless steel sheets, ensuring their longevity and performance.

- Q: What are the color options for stainless steel sheets?

- Stainless steel sheets generally come in a variety of color options, depending on the specific type of finish applied to the surface. The most common color options for stainless steel sheets include silver, which is the natural color of stainless steel, as well as black, gold, bronze, and copper. These colors are achieved through processes such as powder coating, PVD coating, or chemical treatments, which create a thin layer on the surface of the stainless steel sheet. The color options allow for greater versatility in design and can be chosen to complement different aesthetics and applications.

- Q: Can stainless steel sheets be used for outdoor furniture?

- Indeed, outdoor furniture can make use of stainless steel sheets. Stainless steel, a material known for its exceptional durability and resistance to rust, corrosion, and weathering, proves to be an excellent choice. Its ability to withstand the elements ensures that it maintains its appearance and structural integrity over time, making it the perfect option for outdoor furniture. Moreover, stainless steel possesses a sleek and contemporary aesthetic that complements a wide range of outdoor design styles. Whether one seeks stainless steel sheets for tables, chairs, or any other outdoor furniture pieces, they can be assured of a visually appealing and enduring choice.

- Q: Can stainless steel sheets be used for railway infrastructure?

- Yes, stainless steel sheets can be used for railway infrastructure. Stainless steel is known for its durability, corrosion resistance, and strength, making it suitable for various applications in the railway industry. It can be used for railway tracks, bridges, platforms, and other structures that require high strength and long-lasting performance. Additionally, stainless steel's low maintenance requirements and ability to withstand harsh environmental conditions make it an ideal choice for railway infrastructure.

- Q: Can stainless steel sheets be used in the aerospace industry?

- Yes, stainless steel sheets can be used in the aerospace industry. Stainless steel is a versatile material that offers a high strength-to-weight ratio, corrosion resistance, and excellent mechanical properties, making it suitable for various aerospace applications. It is commonly used in the construction of aircraft components such as structural frames, engine parts, exhaust systems, and fuel tanks. Stainless steel sheets are also utilized in the production of aerospace fasteners, fittings, and interior cabin components. Its durability and resistance to temperature variations and extreme environments make it a reliable choice for the aerospace industry.

- Q: Can stainless steel sheets be used in marine environments?

- Yes, stainless steel sheets can be used in marine environments. Stainless steel is highly resistant to corrosion, making it suitable for marine applications where it will be exposed to saltwater and high humidity. It is commonly used in marine vessels, offshore platforms, and other structures that require durability and resistance to rust and corrosion.

- Q: Do stainless steel sheets require any special maintenance?

- Stainless steel sheets do not require any special maintenance, but they do need regular cleaning to maintain their appearance and prevent corrosion. Unlike other materials, stainless steel is resistant to staining, rust, and corrosion, making it relatively low-maintenance. However, it is important to clean stainless steel sheets regularly to remove dirt, debris, and fingerprints that can diminish their shine. To clean stainless steel sheets, simply use a soft cloth or sponge with mild soap and warm water, avoiding abrasive cleaners or scrub brushes that can scratch the surface. Additionally, it is recommended to dry the sheets thoroughly after cleaning to prevent water spots or marks. By following these simple cleaning instructions, stainless steel sheets can maintain their beauty and functionality for years to come.

- Q: Are stainless steel sheets suitable for hygienic applications?

- Stainless steel sheets prove to be highly suitable for applications requiring strict cleanliness and hygiene standards. Their exceptional corrosion resistance renders them ideal for environments with such requirements. The material's non-porous nature ensures it neither absorbs liquids nor harbors bacteria, thus simplifying cleaning and maintenance. Moreover, the smooth and polished surface of stainless steel discourages the accumulation of dirt, grime, and bacteria. Thanks to its durability and strength, stainless steel sheets resist scratches and dents, ensuring a long-lasting and hygienic surface. Because of these hygienic properties, stainless steel sheets find common use in the food and beverage industry, pharmaceutical industry, healthcare facilities, and laboratories.

- Q: What are the different types of stainless steel sheet embossing patterns available?

- There are several different types of stainless steel sheet embossing patterns available. Some of the most common patterns include: 1. Diamond: This pattern features a series of diamond-shaped indentations evenly spaced across the surface of the sheet. It creates a visually appealing and textured appearance. 2. Linen: The linen pattern resembles the texture of linen fabric, with a series of parallel lines running in one direction and perpendicular lines intersecting them. It adds a subtle and sophisticated look to stainless steel sheets. 3. Stucco: The stucco pattern creates a raised, pebble-like texture on the surface of the sheet. It is commonly used in architectural applications to add visual interest and a tactile feel. 4. Leather: This pattern replicates the texture of leather, with a series of irregular lines and indentations. It provides a unique and luxurious appearance to stainless steel sheets. 5. Hammered: The hammered pattern features a series of irregular indentations that resemble the marks made by a hammer. It adds a rustic and handcrafted look to stainless steel sheets. 6. Checkerboard: This pattern consists of a grid of squares, with alternating squares raised or recessed. It creates a classic and geometric design on stainless steel sheets. 7. Wave: The wave pattern features a series of curved lines that resemble ocean waves. It adds a dynamic and flowing look to stainless steel sheets. These are just a few examples of the many different types of stainless steel sheet embossing patterns available. Each pattern can be customized in terms of size, depth, and spacing to suit specific design preferences and applications.

- Q: Are stainless steel sheets resistant to acetic acid?

- Yes, stainless steel sheets are generally resistant to acetic acid.

Send your message to us

Stainless Steel Sheet 4K Surface Treatment 0.9mmx1220mmx2440mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords