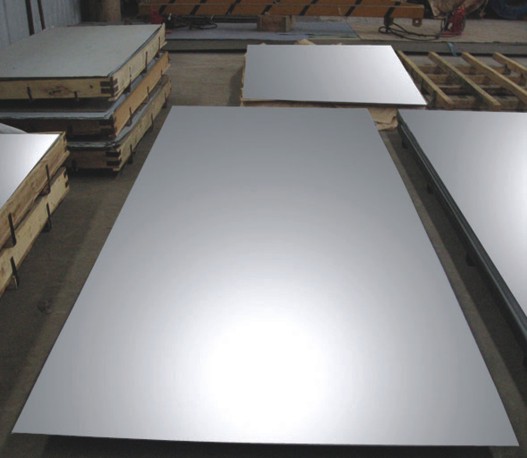

Stainless Steel Sheet 4K Surface Treatment 2mmx1220mmx2440mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction of Stainless Steel Sheet 4K Surface Treatment 2mmx1220mmx2440mm:

Our Stainless Steel products including the stainless steel sheet/plate, stainless steel coil, stainless steel rod/bar, stainless steel angle, stainless steel strip, stainless steel flat, carbon steel products and alloy steel materials. It also can supply the processing of surface, like No.4, BA, HL, SB, 8K, and so on.

Loading Quantity of Stainless Steel Sheet 4K Surface Treatment 2mmx1220mmx2440mm: 25 Tons/20FCL.

Grade of Stainless Steel Sheet 4K Surface Treatment 2mmx1220mmx2440mm: 201, 306, 316 Etc.

Delivery Time of Stainless Steel Sheet 4K Surface Treatment 2mmx1220mmx2440mm: 20 days Per Container.

Application of Stainless Steel Sheet 4K Surface Treatment 2mmx1220mmx2440mm:

| Finish | Thickness | Characteristics | Applications |

| No. 1 | 3.0mm~50.0mm | Finished by hot-rolling, annealing and pickling, characterized by white pickled surface | Chemical industry equipment, Industrial tanks |

| No. 2B | 0.3mm~6.0mm | Finished by heat treatment, pickling after cold rolling, followed by skin pass line to be more brighter and smooth surface | General Application Medical Instruments,Tableware |

| No. BA (Bright Annealed) | 0.5mm~2.0mm | Bright heat treatment after cold rolling | Kitchen utensil, kitchen ware,architectural purpose |

| No. 4 | 0.4mm~3.0mm | Polishing with No. 150 to No.180 mesh abrasivesThe most popular finishes | Milk & Food processing acilities, Hospital Equipment, Bath-tub |

| HL(Hair Line) | 0.4mm~3.0mm | Finished by continuous linear polishing | Architectural purposes, escalators, kitchen ware vehicles |

FAQ

Q: CAN YOU PROVIDE MILL TEST CERTIFICATE?

A: YES! Mill Test Certificate for Stainless Steel Sheet 4K Surface Treatment 2mmx1220mmx2440mm are available.

Q: CAN YOU MAKE DDQ (DEEP DRAWING QUALITY)?

A: YES. Our material has been widely used for producing Stainless Steel Pots and Stainless Steel Sinks, which have strict request for good deep drawing quality.

Q: HOW TO GET A SAMPLE?

A: FREE Stainless Steel Sheet 4K Surface Treatment 2mmx1220mmx2440mm are available for your checking and testing. And to get free samples, you need to send us you detailed receiving address (including post code) and your DHL/FedEx/UPS account for collecting samples, courier cost will be paid in your side.

- Q: Can stainless steel sheets be used for automotive applications?

- Certainly, automotive applications can make use of stainless steel sheets. Renowned for its versatility and durability, stainless steel proves to be an exceptional material that exhibits remarkable resistance against corrosion, heat, and impact. These exceptional qualities render it highly suitable for automotive applications wherein durability and resistance against harsh environments are crucial aspects. Stainless steel sheets find utility across various domains of the automotive industry, encompassing body panels, exhaust systems, fuel tanks, and even interior components. Moreover, stainless steel can be effortlessly shaped, welded, and manipulated to meet precise design prerequisites, thus solidifying its status as a favored option within the automotive industry.

- Q: What are the common sizes of stainless steel sheets?

- The common sizes of stainless steel sheets vary, but some common dimensions include 4 feet by 8 feet, 5 feet by 10 feet, and 4 feet by 12 feet.

- Q: Are stainless steel sheets suitable for elevator wall panels?

- Indeed, elevator wall panels can be made from stainless steel sheets. The use of stainless steel is quite popular for such panels due to its strong and enduring nature, as well as its ability to resist corrosion. Given that elevators are areas with high foot traffic, it is crucial to select a material that can withstand constant usage and potential impact. Stainless steel sheets are resilient and can endure the wear and tear associated with elevator usage. Moreover, stainless steel possesses a remarkable resistance to corrosion, making it a suitable choice for environments that experience high humidity or exposure to chemicals. Furthermore, stainless steel adds a sleek and contemporary touch to the interior of elevators, enhancing their elegance. Overall, stainless steel sheets are a dependable and visually pleasing option for elevator wall panels.

- Q: What about black titanium stainless steel?

- A black titanium stainless steel plate in recent years a large number of signs used in industry (the back of the board also has some kind of black ash), not the actual titanium plate, the layer of black and no titanium metal components, stainless steel should be black.

- Q: Are stainless steel sheets resistant to alkaline solutions?

- Yes, stainless steel sheets are generally resistant to alkaline solutions. Stainless steel is known for its corrosion-resistant properties, and it can withstand exposure to a wide range of chemicals, including alkalis. The high chromium content in stainless steel forms a protective oxide layer on the surface, which helps to prevent corrosion and deterioration. However, it is important to note that the resistance of stainless steel to alkaline solutions may vary depending on the specific grade and composition of the stainless steel. In some cases, prolonged exposure to highly concentrated alkaline solutions or exposure to certain aggressive alkaline substances may cause damage to the stainless steel surface. Therefore, it is advisable to consult with the manufacturer or supplier to ensure the appropriate grade of stainless steel is selected for specific alkaline applications.

- Q: When milling the stainless steel plate, how can he deform?

- 2. clamping points should be selected so that the workpiece does not vibrate when it is machined3., tools should be selected, choose easy to cut stainless steel cutting tools

- Q: What is the function of a stainless steel plate at the top of the steel chimney?

- Many stainless steel grades, different properties, and in the course of its development has gradually formed several categories. According to the structure of the organization, it is divided into four categories: martensitic stainless steel (including precipitation hardening stainless steel), ferritic stainless steel, austenitic stainless steel and austenitic ferrite duplex stainless steel;

- Q: What is the maximum width available for stainless steel sheets?

- The maximum width available for stainless steel sheets can vary depending on the manufacturer and supplier. However, in general, stainless steel sheets are commonly available in widths ranging from 36 inches (0.91 meters) to 72 inches (1.83 meters). Some manufacturers may offer even wider options for specialized applications. It is always advisable to check with the specific supplier or manufacturer for the maximum width available, as it may vary based on their production capabilities and product offerings.

- Q: Can stainless steel sheets be used for elevator wall panels?

- Yes, stainless steel sheets can be used for elevator wall panels. Stainless steel is a durable and corrosion-resistant material, making it suitable for high-traffic areas like elevators. Its sleek and modern appearance also enhances the overall aesthetics of the elevator interior.

- Q: Are stainless steel sheets good for chemical processing?

- Yes, stainless steel sheets are ideal for chemical processing due to their exceptional corrosion resistance, high strength, and durability. They can withstand exposure to various chemicals, acids, and alkalis without getting corroded or contaminated, making them an excellent choice for such applications.

Send your message to us

Stainless Steel Sheet 4K Surface Treatment 2mmx1220mmx2440mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords