best stainless steel plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000ton m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

stainless steel sheet

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely used in light industry,heavy industry,daily necessities and the decoration industry.my company long term supply stainless steel porducts including:stainless steel sheet,stainless steelcoil and stainless steel tube.

Specifications

stainless steel sheet

1.Surface:2B/BA/4K/6K/8K

2.Thickness:0.3-3mm

3.Width:1m 1.219m 1.5m

4.Length:1.5m 6m or as your requirement

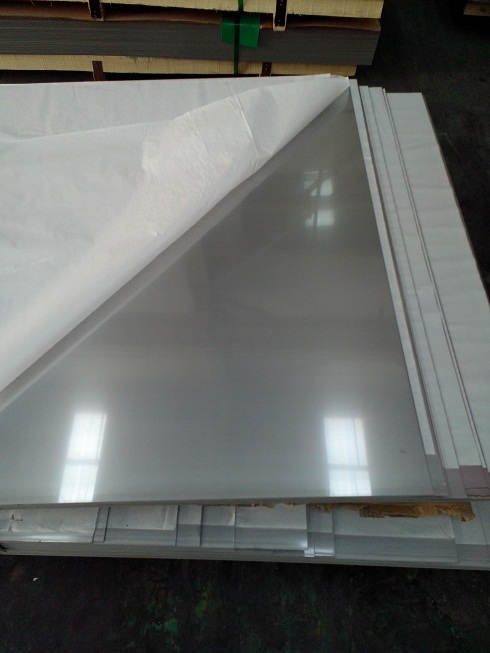

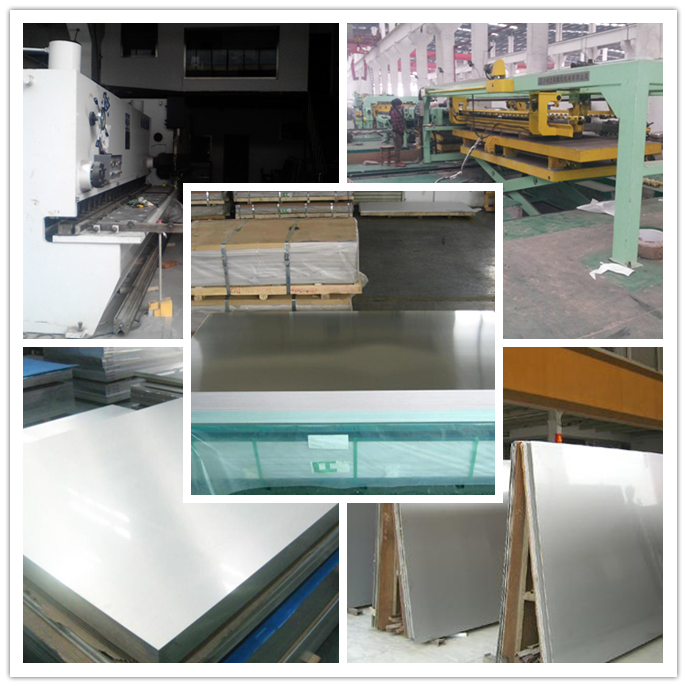

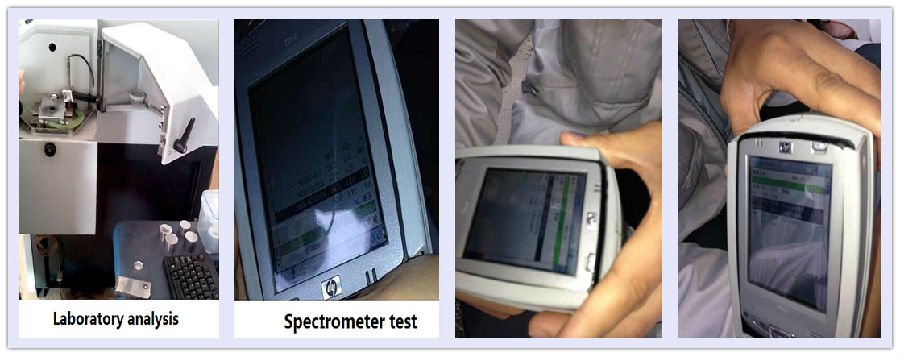

A series of picturs

A series of pictures

A series of pictures

A series of pictures

- Q: Are stainless steel sheets resistant to humidity?

- Yes, stainless steel sheets are highly resistant to humidity. Their composition, primarily consisting of iron, chromium, and nickel, forms a protective layer that prevents corrosion and rusting even in high humidity environments. This makes stainless steel sheets an excellent choice for applications where moisture resistance is crucial, such as in kitchen and bathroom fixtures, outdoor structures, and marine equipment.

- Q: What's the difference between cold rolled plate and stainless steel?

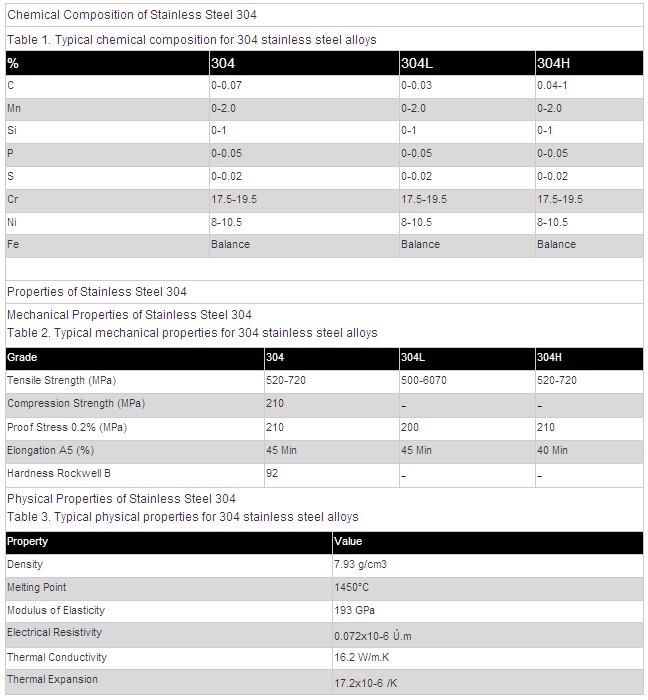

- The biggest difference between the stainless steel plate is the addition of 13% chromium (Cr) elements and even nickel elements (such as the standard 304 stainless steel, chromium containing 18%, nickel containing 9%) during steelmaking, thus having the function of stainless steel

- Q: Can stainless steel sheets be recycled?

- Yes, stainless steel sheets can be recycled. Stainless steel is a highly recyclable material, and its recycling rate is one of the highest among all materials. When stainless steel sheets reach the end of their useful life, they can be collected and sent to a recycling facility. The recycling process involves melting down the stainless steel sheets and reforming them into new products, without losing their properties or quality. This makes stainless steel a sustainable and environmentally friendly material choice. Recycling stainless steel also helps to conserve natural resources, reduce energy consumption, and minimize waste.

- Q: How do you remove rust or corrosion from stainless steel sheets?

- In order to eliminate rust or corrosion from stainless steel sheets, the following steps can be followed: 1. Initiate the process by cleansing the surface of the stainless steel sheet using a mild detergent and warm water. This will eradicate any dirt or grease that may potentially impede the rust removal procedure. 2. Subsequently, ensure the sheet is thoroughly dried to prevent any further water damage and to guarantee the effectiveness of the rust removal process. 3. Proceed by utilizing a non-abrasive scrubbing pad or a soft cloth to apply a stainless steel cleaner or a homemade solution comprising equal parts vinegar and water. Gently rub the affected area in the direction of the grain of the stainless steel. 4. If the rust or corrosion persists, experiment with a paste formed from baking soda and water or a mixture of cream of tartar and water. Apply this paste to the affected region and allow it to sit for approximately 15 minutes. Then, delicately scrub the area with a soft cloth or a non-abrasive scrubbing pad. 5. If the aforementioned methods do not completely eliminate the rust or corrosion, consider using a commercial rust remover specifically formulated for stainless steel. Make sure to adhere to the manufacturer's instructions and adopt suitable safety precautions. 6. Once the rust or corrosion has been eradicated, rinse the stainless steel sheet thoroughly with clean water and completely dry it to prevent any water spots or further damage. 7. To prevent future rust or corrosion, it is advisable to regularly clean and maintain stainless steel surfaces using non-abrasive cleaners and avoiding harsh chemicals or abrasive materials. Always remember to conduct a test of any cleaning solution or rust remover on a small and inconspicuous area of the stainless steel sheet prior to applying it to the entire surface, to ensure it does not cause any damage or discoloration.

- Q: What are the different types of stainless steel sheet surface patterns for architectural purposes?

- Architectural purposes often call for the use of various surface patterns on stainless steel sheets. These patterns are achieved through different techniques, resulting in distinct appearances. Here are some of the popular surface patterns: 1. Brushed: By using a fine abrasive material, the stainless steel sheet is brushed to create a smooth texture with visible brush lines in one direction. This sleek and contemporary pattern is widely favored. 2. Mirror: Achieved by polishing the stainless steel sheet to a high shine, the mirror surface pattern reflects light like an actual mirror. It is commonly chosen for applications where aesthetics and visual impact are important. 3. Embossed: The surface of embossed stainless steel sheets features a raised pattern or design. This is achieved by pressing the sheet between rollers engraved with a specific pattern. It adds texture and depth to architectural applications. 4. Perforated: Perforated stainless steel sheets have evenly distributed small holes or perforations. These can come in various shapes and sizes, allowing for airflow, light transmission, and decorative effects. Façades, screens, and decorative elements often utilize perforated stainless steel sheets. 5. Etched: Etched stainless steel sheets feature designs or patterns that are chemically etched onto the surface. An acid-resistant material is applied and then selectively removed with acid, leaving behind intricate and detailed designs. This pattern is ideal for artistic and decorative purposes. 6. Hammered: Hammered stainless steel sheets have a textured surface resembling hammered metal. This effect is achieved by using a special hammer or mallet to create indentations and surface irregularities. It adds a rustic and handcrafted look to architectural projects. These examples showcase the variety of stainless steel sheet surface patterns commonly used in architecture. Each pattern possesses its own visual and textural qualities, enabling designers and architects to choose the most suitable option for their specific project requirements.

- Q: Can stainless steel sheets be used in decorative applications?

- Certainly, decorative applications can certainly make use of stainless steel sheets. Stainless steel possesses great versatility, allowing it to be shaped, patterned, and finished in a variety of ways, rendering it an exceptional option for decorative purposes. Its sleek and contemporary look adds a dash of sophistication to any area, and it can be utilized in a multitude of ways, such as wall cladding, backsplashes, cabinet fronts, countertops, and furniture embellishments. Moreover, stainless steel sheets exhibit remarkable durability, resistance to corrosion, and ease of maintenance, making them an ideal choice for both indoor and outdoor decorative applications.

- Q: What is the electrical resistivity of stainless steel sheets?

- The electrical resistivity of stainless steel sheets varies depending on the specific grade or alloy composition of the stainless steel. Generally, stainless steel has a relatively low electrical resistivity compared to other materials, such as copper or aluminum. The resistivity can range from approximately 6.9 x 10^-7 ohm-meters (Ωm) for austenitic stainless steel to 7.2 x 10^-7 Ωm for ferritic stainless steel. It is important to note that these values are approximate and can vary slightly based on factors such as temperature and impurities in the stainless steel.

- Q: Can stainless steel sheets be used for cryogenic applications?

- Yes, stainless steel sheets can be used for cryogenic applications. Stainless steel has excellent mechanical properties at low temperatures and provides good resistance to thermal shock and corrosion, making it suitable for cryogenic environments.

- Q: Are stainless steel sheets suitable for decorative purposes?

- Stainless steel sheets are a perfect choice for decorative purposes. They possess a sleek and contemporary appearance, which adds a touch of elegance and sophistication to any given space. The smooth and reflective surface of stainless steel creates a visually pleasing aesthetic that enhances the overall look and feel of a room. Furthermore, stainless steel is incredibly durable and corrosion-resistant, making it an excellent long-term option for decorative use. The versatility of stainless steel sheets allows them to be utilized in various decorative forms, including wall panels, backsplashes, countertops, and even furniture. Regardless of whether they are used in residential or commercial settings, stainless steel sheets can be employed to create remarkable and attention-grabbing decorative elements that perfectly complement any interior design style.

- Q: Are stainless steel sheets suitable for aerospace applications?

- Yes, stainless steel sheets are commonly used in aerospace applications due to their excellent strength, corrosion resistance, and high-temperature capabilities. These sheets are suitable for various components such as aircraft bodies, engine parts, and structural elements, ensuring reliable performance and durability in demanding aerospace environments.

Send your message to us

best stainless steel plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000ton m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords