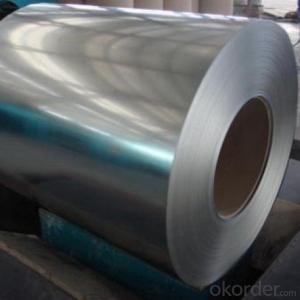

Stainless Steel Coil 304

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Coil 304

1.Thickness:0.4mm-80mm

2. Width:1000mm-1500mm

3. Price:1000USD-4500USD

Size(in mm) | 1000*2000,1220*2440,1250*2500,1500*3000,1500*6000 Or as customer’s requirement |

Thickness(mm) | 0.4-80 |

Specification | A240 |

Grade | 430,409,420,201,202,304,304L,316L,310S, 309and so on |

Certificate | Manufacturer Test Certificate, Laboratory Test Certificate |

Standard | ASTM,GB,JIS, |

Surface | 2B,BA,Mirror,Hair Line,No.4+PVC |

Technique | Cold rolled and hot rolled |

MOQ | 1 ton |

Supply Ability | 1000 tons/month |

Terms of payment | TT or LC |

- Q: Can stainless steel sheets be used for wall cladding?

- Yes, stainless steel sheets can be used for wall cladding. Stainless steel is a durable and long-lasting material that is resistant to corrosion, making it a suitable choice for cladding applications. It provides a sleek and modern appearance, adding an aesthetic appeal to the walls. Stainless steel sheets can be easily installed and maintained, making them an excellent option for both interior and exterior walls. Additionally, stainless steel sheets offer excellent fire resistance and can withstand high temperatures, making them a safe choice for wall cladding.

- Q: How do you prevent intergranular corrosion on stainless steel sheets?

- Intergranular corrosion on stainless steel sheets can be prevented by using low carbon grades of stainless steel, such as the 304L or 316L alloys, which have reduced carbon content. Additionally, heat treatment processes like solution annealing can help eliminate carbide precipitation and reduce the susceptibility to intergranular corrosion. Finally, avoiding exposure to corrosive environments and implementing proper cleaning and maintenance practices can further minimize the risk of intergranular corrosion on stainless steel sheets.

- Q: Can stainless steel sheets be used for railway infrastructure?

- Railway infrastructure can utilize stainless steel sheets, as they offer numerous advantages. Stainless steel is a versatile and enduring material that is well-suited for railway applications. Its resistance to corrosion makes it suitable for outdoor and high humidity environments, which are commonplace in railway infrastructure. Stainless steel sheets can withstand severe weather conditions, such as extreme temperatures, rain, and UV radiation, without deteriorating or corroding. As a result, they are an excellent choice for railway tracks, bridges, tunnels, and other structures that are exposed to the elements. Moreover, stainless steel sheets possess an exceptional strength-to-weight ratio. This characteristic allows for the construction of lightweight yet robust railway infrastructure. Consequently, the overall structure's load is reduced, enabling easier transportation and installation. Stainless steel is also fire-resistant and can withstand significant impact, making it an ideal option for railway applications that prioritize safety. Furthermore, stainless steel sheets are effortless to clean and maintain, which is advantageous for railway infrastructure that necessitates regular upkeep. Their aesthetic appeal can be easily restored through polishing, ensuring a clean appearance. Additionally, stainless steel is recyclable, making it an environmentally friendly choice for sustainable railway construction. To summarize, due to their corrosion resistance, strength, durability, fire resistance, ease of maintenance, and sustainability, stainless steel sheets are indeed suitable for railway infrastructure.

- Q: Can stainless steel sheets be used for hygienic applications?

- Stainless steel sheets are indeed suitable for hygienic applications. The reason lies in its remarkable hygiene properties attributed to the non-porous surface, which effectively resists bacteria, mold, and other microorganisms. Moreover, stainless steel is effortless to clean and maintain, making it perfect for sectors that prioritize cleanliness and hygiene, including the food and beverage industry, healthcare facilities, and pharmaceutical manufacturing. Furthermore, stainless steel exhibits exceptional durability, corrosion resistance, and high-temperature tolerance, rendering it a superb choice for hygienic applications.

- Q: Are stainless steel sheets resistant to pitting and crevice corrosion?

- Yes, stainless steel sheets are highly resistant to pitting and crevice corrosion due to their chromium content, which forms a protective passive layer on the surface, preventing corrosion from occurring.

- Q: How can I classify stainless steel plates?

- The stainless steel plate is classified according to the mode of production: it can be divided into hot rolled steel plate (steel plate heated by reheating furnace) and cold-rolled steel plate (steel plate produced by cold rolling process).

- Q: Are stainless steel sheets suitable for decorative purposes?

- Yes, stainless steel sheets are suitable for decorative purposes. They offer a sleek and modern aesthetic, are highly durable, and can be customized with various finishes and patterns. Additionally, stainless steel is resistant to corrosion, making it a practical choice for both indoor and outdoor decorative applications.

- Q: Are stainless steel sheets resistant to chemicals?

- Generally, chemicals do not pose a problem for stainless steel sheets. Stainless steel is famous for its ability to resist corrosion, which is why it is widely used in industries like chemical processing, pharmaceuticals, and food processing. The presence of elements like chromium and nickel in stainless steel forms a protective layer on its surface, preventing most chemicals from penetrating. However, it's important to note that the resistance to chemicals may vary depending on the grade and composition of the stainless steel used. In highly aggressive environments or when dealing with specific chemicals, it's advisable to consult a materials engineer or refer to compatibility charts to ensure the best stainless steel grade is chosen.

- Q: Can stainless steel sheets be used in high-pressure environments?

- Yes, stainless steel sheets can be used in high-pressure environments. Stainless steel is known for its excellent strength, durability, and corrosion resistance, making it suitable for applications that require withstanding high pressure conditions. The material's ability to resist deformation and maintain its integrity under extreme pressure makes it a preferred choice in industries such as oil and gas, chemical processing, and aerospace.

- Q: Can stainless steel sheets be used for decorative lighting fixtures?

- Yes, stainless steel sheets can certainly be used for decorative lighting fixtures. Stainless steel is a versatile and durable material that can be shaped and formed into various designs and patterns, making it ideal for creating unique and eye-catching lighting fixtures. Its sleek and modern appearance adds a touch of elegance to any space, making it a popular choice for decorative purposes. Additionally, stainless steel is resistant to corrosion and heat, ensuring that the lighting fixtures will remain in excellent condition for a long time.

Send your message to us

Stainless Steel Coil 304

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords