Stainless Steel Sheet/Plate 316 in Multi Fields Usage

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 8500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Sheet/Plate 316 in Multi Fields Usage

Description of Stainless Steel Sheet/Plate 316 in Multi Fields Usage:

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widelyused in light industry,heavy industry,daily necessities and the decoration industry.my company long-termsupply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube.

Main Features of Stainless Steel Sheet/Plate 316 in Multi Fields Usage:

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Application of Stainless Steel Sheet/Plate 316 in Multi Fields Usage:

Stainless steel’s resistance to corrosion and staining, low maintenance and familiar lustre make it an ideal material for many application

s.There are over 150 grades of stainless steel, of which fifteen are most commonly used. The alloy is milled into coils, sheets, plates,

bars, wire, and tubing to be used in cookware, cutlery, household hardware, surgical instruments, major appliances, industrial equipme

nt Storage tanks and tankers used to transport orange juice and other food are often made of stainless steel, because of its corrosion re

sistance and antibacterial properties. This also influences its use in commercial kitchens and food processing plants, as it can be steam

cleaned and sterilized and does not need paint or other surface finishes..

Specifications of Stainless Steel Sheet/Plate 316 in Multi Fields Usage:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

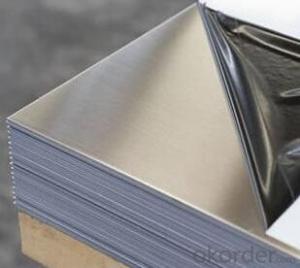

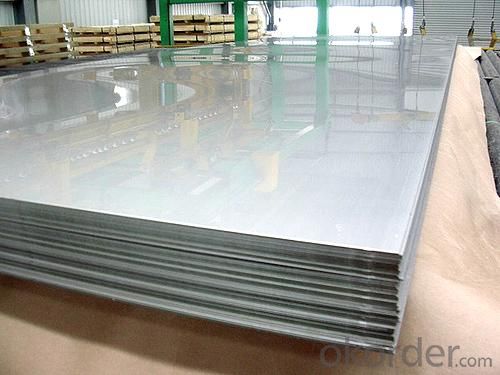

Surface Finish Characteristics Stainless Steel Sheet/Plate 316 in Multi Fields Usage:

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

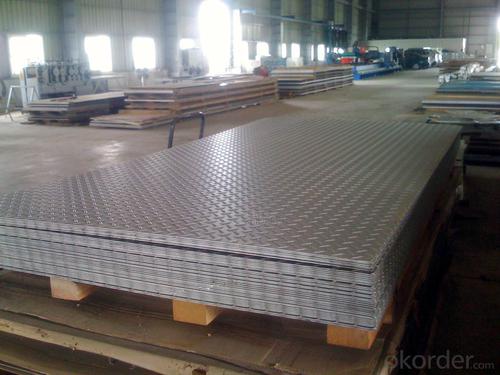

Images of Stainless Steel Sheet/Plate 316 in Multi Fields Usage:

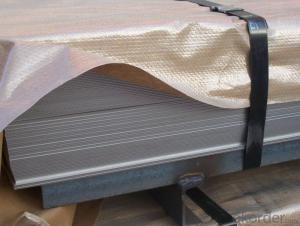

Sandard Seaworth Packing(wooden packing with water proof paper):

FAQ of Stainless Steel Sheet/Plate 316 in Multi Fields Usage:

1. What are we supplying?

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently supplying grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321, 410/420/430/443/444/409L, and 904L.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Can stainless steel sheets be used for kitchen utensils?

- Yes, stainless steel sheets can be used for kitchen utensils. Stainless steel is a popular choice for kitchen utensils because it is durable, easy to clean, and resistant to rust and corrosion. Stainless steel sheets can be shaped and formed into various utensils such as spoons, forks, knives, spatulas, and more. Additionally, stainless steel is non-reactive, meaning it does not leach any harmful chemicals into food, making it a safe option for cooking and eating utensils. Overall, stainless steel sheets are a great material choice for kitchen utensils due to their strength, hygiene, and longevity.

- Q: 1cm thick 201 stainless steel plate how much money party

- 1 thick 201 stainless steel sheet, 95 yuan / square meters.Stainless steel (Stainless Steel) is stainless acid resistant steel abbreviation, resistant to air, steam

- Q: What is the specific heat capacity of stainless steel sheets?

- The specific heat capacity of stainless steel sheets can vary depending on the specific grade and composition of the stainless steel. However, on average, the specific heat capacity of stainless steel is around 500 J/kg°C. This means that for every kilogram of stainless steel, it would require 500 joules of energy to raise the temperature by 1 degree Celsius. It is important to note that this value may not be exact for all types of stainless steel, so it is recommended to consult specific technical data or reference materials for accurate and precise values.

- Q: What are stainless steel sheets used for?

- Stainless steel sheets serve a multitude of purposes in diverse industries. Their outstanding resistance to corrosion, durability, and attractive appearance make them highly sought after in both commercial and residential settings. Within the construction field, these sheets are utilized for roofing, cladding, and facades due to their ability to withstand harsh environmental conditions while providing a contemporary and sleek look. In the automotive industry, they are frequently employed in the construction of car bodies, exhaust systems, and decorative trims. Furthermore, stainless steel sheets find extensive use in the food and beverage sector, where their hygienic qualities make them ideal for kitchen equipment, countertops, and food processing machinery. Additionally, they are widely used in medical equipment, pharmaceuticals, and laboratory settings due to their resistance to corrosion and ease of cleaning. They are also employed in furniture, appliances, signage, and for decorative purposes, as they can be easily customized and molded into various shapes and sizes. All in all, stainless steel sheets are an adaptable material that fulfills a diverse array of requirements in different industries, owing to their strength, durability, and corrosion resistance properties.

- Q: How do you restore the shine or finish on stainless steel sheets?

- To restore the shine or finish on stainless steel sheets, there are a few methods you can try: 1. Cleaning with warm water and soap: Start by cleaning the stainless steel sheets with warm water and a mild dish soap. Use a soft cloth or sponge to gently scrub the surface, then rinse with clean water and dry thoroughly with a clean cloth. This should remove any dirt or grime that is dulling the shine. 2. Vinegar solution: If the stainless steel sheets have stubborn stains or dull spots, you can try using a vinegar solution. Mix equal parts white vinegar and water in a spray bottle, then spray the solution onto the surface. Let it sit for a few minutes, then wipe it off with a soft cloth. Vinegar helps to remove stains and restore shine to stainless steel. 3. Baking soda paste: For tougher stains or scratches on stainless steel sheets, you can create a paste using baking soda and water. Mix enough baking soda with water to form a thick paste, then apply it to the stained areas. Gently scrub the surface with a soft cloth or sponge, moving in the direction of the grain. Rinse with water and dry thoroughly. 4. Stainless steel cleaner: There are commercial stainless steel cleaners available that are specifically designed to restore the shine and finish of stainless steel. Follow the instructions on the cleaner and apply it to the surface using a soft cloth or sponge. Rub gently in the direction of the grain and rinse with water. Dry thoroughly to avoid water spots. Remember, always test any cleaning method or solution on a small, inconspicuous area of the stainless steel sheet before applying it to the entire surface. This will help ensure that the method or solution does not cause any damage or discoloration.

- Q: Are stainless steel sheets available in different patterns?

- Yes, stainless steel sheets are available in different patterns. Stainless steel is a versatile material that can be manipulated in various ways to create unique patterns and designs. Some common patterns include brushed, satin, mirror, diamond, and checker plate. These patterns not only enhance the aesthetic appeal of stainless steel sheets but also offer functional benefits such as increased slip resistance or improved durability. Whether you are looking for a sleek and modern look or a more textured and decorative finish, there are numerous options available in stainless steel sheets to suit your needs.

- Q: How do you calculate the weight of a stainless steel sheet?

- To calculate the weight of a stainless steel sheet, you need to know its dimensions (length, width, and thickness) and the specific gravity of stainless steel. First, determine the volume of the stainless steel sheet by multiplying the length, width, and thickness together. This will give you the volume in cubic units. Next, multiply the volume by the specific gravity of stainless steel, which is typically around 7.93 g/cm³ (grams per cubic centimeter). This will give you the weight of the stainless steel sheet in grams. To convert the weight to a different unit, such as kilograms or pounds, divide the weight in grams by the appropriate conversion factor. For example, to convert grams to kilograms, divide by 1000. To convert grams to pounds, divide by 453.59237. It is important to note that this calculation provides an estimate of the weight, as there may be slight variations in the specific gravity of stainless steel depending on the exact alloy and composition of the sheet.

- Q: Are stainless steel sheets suitable for nuclear power plants?

- Yes, stainless steel sheets are suitable for use in nuclear power plants. Stainless steel is a widely used material in the nuclear industry due to its unique properties that make it suitable for such high-risk environments. Firstly, stainless steel has excellent corrosion resistance, which is crucial in nuclear power plants where the presence of corrosive substances can be high. Corrosion can compromise the structural integrity of materials, leading to safety hazards and potential failures. Stainless steel's resistance to corrosion helps ensure the longevity and reliability of equipment and structures in nuclear power plants. Secondly, stainless steel has high strength and toughness, making it capable of withstanding extreme conditions such as high temperatures and pressures that are present in nuclear power plants. This strength and toughness enable stainless steel to withstand the harsh environment and potential mechanical stresses that can occur during normal operation or accidents. Additionally, stainless steel has good heat resistance, which is important in nuclear power plants where high temperatures are generated during the nuclear fission process. Stainless steel's ability to retain its strength and structural integrity even at elevated temperatures makes it suitable for containing and handling radioactive materials and hot fluids. Furthermore, stainless steel is easy to clean and maintain, which is crucial in nuclear power plants where cleanliness and sterility are essential. Regular cleaning and maintenance are required to prevent the build-up of radioactive contaminants and ensure the safe and efficient operation of equipment and systems. Overall, stainless steel sheets are highly suitable for use in nuclear power plants due to their corrosion resistance, strength, toughness, heat resistance, and ease of maintenance. The use of stainless steel helps ensure the safety, reliability, and longevity of equipment and structures, contributing to the overall efficiency and effectiveness of nuclear power plants.

- Q: What is the lifespan of stainless steel sheets?

- The lifespan of stainless steel sheets can vary depending on various factors such as the grade of stainless steel, the environment in which they are used, and the maintenance practices followed. In general, stainless steel sheets have a long lifespan and are known for their durability and corrosion resistance. They are designed to withstand harsh conditions and are resistant to rust, stains, and other forms of degradation. Stainless steel sheets are typically made from austenitic stainless steel, which is known for its high levels of chromium and nickel. These elements provide excellent corrosion resistance and make stainless steel sheets highly resistant to rust and staining. As a result, stainless steel sheets can last for many years, often outlasting other materials such as aluminum or regular steel. The lifespan of stainless steel sheets can be further extended through proper care and maintenance. Regular cleaning and removal of any contaminants or debris can help prevent corrosion and maintain the appearance and performance of the sheets. Additionally, applying protective coatings or finishes can provide an extra layer of protection against corrosion and wear. While it is difficult to provide an exact lifespan for stainless steel sheets due to the variability of factors involved, with proper care and maintenance, they can easily last for several decades. In some cases, stainless steel sheets have been known to last for over a century. Therefore, investing in stainless steel sheets is often seen as a long-term solution, offering durability and cost-effectiveness over an extended period.

- Q: Can stainless steel sheets be used in high-pressure environments?

- High-pressure environments can certainly accommodate the use of stainless steel sheets. Renowned for remarkable strength and corrosion resistance, stainless steel proves itself fitting for tasks demanding high-pressure endurance. It remains intact and unyielding under immense pressure, never succumbing to deformation or fracture. Consequently, it emerges as an ideal choice for industries like oil and gas, chemical processing, and power generation, which frequently operate in high-pressure settings. Furthermore, stainless steel sheets retain their structural integrity and performance at elevated temperatures, bolstering their already impressive suitability for high-pressure situations.

Send your message to us

Stainless Steel Sheet/Plate 316 in Multi Fields Usage

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 8500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords