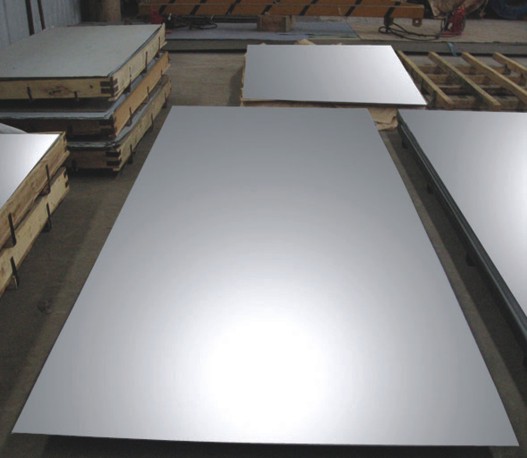

Stainless Steel Sheet 2B Surface Treatment 4mmx1240mmx2440mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction of Stainless Steel Sheet 2B Surface Treatment 4mmx1240mmx2440mm:

Our Stainless Steel products including the stainless steel sheet/plate, stainless steel coil, stainless steel rod/bar, stainless steel angle, stainless steel strip, stainless steel flat, carbon steel products and alloy steel materials. It also can supply the processing of surface, like No.4, BA, HL, SB, 8K, and so on.

Loading Quantity of Stainless Steel Sheet 2B Surface Treatment 4mmx1240mmx2440mm:

25 Tons/20FCL.

Grade of Stainless Steel Sheet 2B Surface Treatment 4mmx1240mmx2440mm: 201, 306, 316 Etc.

Delivery Time of Stainless Steel Sheet 2B Surface Treatment 4mmx1240mmx2440mm: 20 days Per Container.

Application of Stainless Steel Sheet 2B Surface Treatment 4mmx1240mmx2440mm:

| Finish | Thickness | Characteristics | Applications |

| No. 1 | 3.0mm~50.0mm | Finished by hot-rolling, annealing and pickling, characterized by white pickled surface | Chemical industry equipment, Industrial tanks |

| No. 2B | 0.3mm~6.0mm | Finished by heat treatment, pickling after cold rolling, followed by skin pass line to be more brighter and smooth surface | General Application Medical Instruments,Tableware |

| No. BA (Bright Annealed) | 0.5mm~2.0mm | Bright heat treatment after cold rolling | Kitchen utensil, kitchen ware,architectural purpose |

| No. 4 | 0.4mm~3.0mm | Polishing with No. 150 to No.180 mesh abrasivesThe most popular finishes | Milk & Food processing acilities, Hospital Equipment, Bath-tub |

| HL(Hair Line) | 0.4mm~3.0mm | Finished by continuous linear polishing | Architectural purposes, escalators, kitchen ware vehicles |

Specification of Stainless Steel Sheet 2B Surface Treatment 4mmx1240mmx2440mm:

Type | Wuxi boro-304/304L/316/316L/321/309S/310S/904L/202/201/430 stainless steel sheet |

Thinckness | 0.3mm-60mm |

Widthness | 50mm~2000mm or customized |

Length | 1000mm~8000mm or customized |

Brand name | CNBM |

Standard | JIS, AISI, ASTM, GB, DIN, EN |

Material | 201/201/304/304L/316/316L/321/309S/310S/904L stainless steel sheet |

Surface | 2B,BA,HL,BK,NO.1,NO.4,8K,SB,etc |

Certificate | We accept the third inspections--SGS-BV etc. |

Application | Bridge, Shipbuilding,roofing,Car, etc |

Standard sheet sizes | 1000mm*2000mm,1250mm*2500mm,1219mm*2438mm,1500mm*3000mm We can produce other standard as customized |

FAQ

Q: CAN YOU PROVIDE MILL TEST CERTIFICATE?

A: YES! Mill Test Certificate for Stainless Steel Sheet 2B Surface Treatment 4mmx1240mmx2440mm are available.

Q: CAN YOU MAKE DDQ (DEEP DRAWING QUALITY)?

A: YES. Our material has been widely used for producing Stainless Steel Pots and Stainless Steel Sinks, which have strict request for good deep drawing quality.

Q: HOW TO GET A SAMPLE?

A: FREE samples for Stainless Steel Sheet 2B Surface Treatment 4mmx1240mmx2440mm are available for your checking and testing. And to get free samples, you need to send us you detailed receiving address (including post code) and your DHL/FedEx/UPS account for collecting samples, courier cost will be paid in your side.

- Q: Stainless steel plate net price, stainless steel plate net how much one meter?

- 201, in fact, people say stainless steel; 304 stainless steel sheet is the most widely used material; 316 and 316L stainless steel plate is different from carbon content, nickel content is different.

- Q: How to clean stainless steel plate cleaning?

- Grease can be applied to soft cloth to dissolve alcohol. I was impressed with how the grease turned off my pizza oven. Some thicker deposits did not respond once to a cloth, but I had been rubbing them with alcohol and completely disappeared within one or two minutes. With other methods, it is important to rinse off the alcohol and dry it so that it has a shiny metal.

- Q: How about stainless steel grades?

- According to the composition can be divided into Cr (400 Series), Cr Ni system (300 Series), Cr Mn Ni (200 Series) and the precipitation hardening systems (Series 600). 200 series - chromium nickel manganese austenitic stainless steel 300 series - chromium nickel austenitic stainless steel 301 - ductility, used for molding products. It can also be hardened rapidly by mechanical processing. Good weldability. The abrasion resistance and fatigue strength are better than 304 stainless steel. 302 - 304 with corrosion resistance, due to the relatively high carbon intensity. 303 - by adding a small amount of sulfur and phosphorus, it is easier to cut than 304.

- Q: What are the common uses of stainless steel sheets in the food industry?

- Stainless steel sheets are commonly used in the food industry for various purposes such as food processing equipment, countertops, sinks, storage tanks, and machinery. The material's corrosion resistance, durability, and ease of cleaning make it ideal for maintaining hygienic conditions and preventing contamination in food preparation and storage areas.

- Q: Do stainless steel sheets require any special handling or storage?

- Special handling and storage are necessary for maintaining the quality and preventing damage of stainless steel sheets. Consider the following essential points: 1. Gloves must be worn while handling stainless steel sheets to prevent leaving fingerprints and oils on the surface, which can cause corrosion. Moreover, sharp tools should be avoided to prevent any surface scratching. 2. To avoid rust or corrosion during storage, stainless steel sheets should be thoroughly cleaned to remove dirt, debris, and moisture. Cleaning can be done using mild soap or a specialized stainless steel cleaner. 3. It is crucial to store stainless steel sheets in a clean, dry, and well-ventilated area. Direct sunlight, extreme temperatures, and moisture should be avoided as they can lead to corrosion. Ideally, the sheets should be stored in a covered area or wrapped in protective materials like plastic or cloth to prevent scratches and damage. 4. Sheets should be separated to prevent contact and potential scratching or damage. This can be achieved by using dividers or interleaf papers between the sheets. 5. When moving or transporting stainless steel sheets, it is advisable to use appropriate handling equipment such as forklifts or cranes. This ensures safe and secure movement without causing any dents or scratches. By adhering to these guidelines for handling and storage, stainless steel sheets can be effectively protected and maintained in optimal condition for their intended use.

- Q: Can stainless steel sheets be used for chemical storage tanks?

- Yes, stainless steel sheets can be used for chemical storage tanks. Stainless steel is highly resistant to corrosion and rust, making it an ideal material for storing chemicals, including acids, alkalis, and other corrosive substances. The high strength and durability of stainless steel ensure that the tanks can withstand the pressure and weight of the stored chemicals. Additionally, stainless steel is non-reactive, meaning it does not react with most chemicals, ensuring the purity and integrity of the stored substances. Stainless steel's smooth surface also makes it easy to clean and maintain, reducing the risk of contamination. Overall, stainless steel sheets are a reliable and suitable choice for chemical storage tanks.

- Q: What are the applications of stainless steel sheets in the construction industry?

- Stainless steel sheets have various applications in the construction industry due to their unique properties and characteristics. Here are some of the key applications of stainless steel sheets in construction: 1. Roofing and Cladding: Stainless steel sheets are widely used for roofing and cladding in commercial and residential buildings. They provide excellent resistance against corrosion, harsh weather conditions, and fire, making them a durable and long-lasting option. 2. Facades and Curtain Walls: Stainless steel sheets are frequently used in the construction of facades and curtain walls. Their attractive appearance, high strength, and resistance to staining and fading make them a popular choice for creating visually appealing and low-maintenance building exteriors. 3. Structural Components: Stainless steel sheets find applications in the construction of various structural components, such as beams, columns, and support systems. Their high strength-to-weight ratio, resistance to deformation, and durability make them ideal for ensuring the structural integrity of buildings. 4. Handrails and Balustrades: Stainless steel sheets are commonly used for designing handrails, balustrades, and guardrails in both indoor and outdoor settings. They offer excellent resistance to corrosion, impact, and wear, while their sleek and modern appearance adds an aesthetic touch to the overall design. 5. Kitchen and Bathroom Fixtures: Stainless steel sheets are extensively used for fabricating kitchen and bathroom fixtures, such as sinks, countertops, backsplashes, and shower enclosures. Their resistance to moisture, heat, and stains, along with their easy maintenance, make them a practical and hygienic choice. 6. Interior Design Elements: Stainless steel sheets are utilized in the construction of various interior design elements, including wall panels, ceiling panels, elevator interiors, and decorative screens. Their smooth and reflective surface, combined with their versatility in terms of finishes and patterns, allows for creating visually appealing and modern interiors. 7. HVAC Systems: Stainless steel sheets are often used in HVAC (heating, ventilation, and air conditioning) systems due to their high-temperature resistance, corrosion resistance, and ease of cleaning. They are commonly employed in ductwork, air handling units, and exhaust systems to ensure efficient and durable performance. Overall, stainless steel sheets offer numerous advantages in the construction industry, including durability, corrosion resistance, low maintenance requirements, and aesthetic appeal. These qualities make them a preferred choice for a wide range of applications, contributing to the overall quality and longevity of construction projects.

- Q: What is the difference between stainless steel sheets and regular steel sheets?

- Stainless steel sheets and regular steel sheets differ primarily in their composition and properties. Stainless steel sheets are made primarily of iron and contain a minimum of 10.5% chromium, which gives them their unique stainless properties. Regular steel sheets, on the other hand, are made primarily of iron and carbon, with no significant amount of chromium. The presence of chromium in stainless steel sheets provides several distinct advantages. Firstly, it enhances the corrosion resistance of the material, making it highly resistant to rust and staining. This makes stainless steel sheets suitable for applications in environments where moisture or exposure to corrosive substances is a concern, such as in the food and beverage industry or marine applications. Additionally, stainless steel sheets have excellent heat resistance, making them suitable for high-temperature applications. They can withstand extreme temperatures without losing their structural integrity, which regular steel sheets may not be able to tolerate. Another key difference lies in the appearance of the two materials. Stainless steel sheets have a bright, reflective surface due to their chromium content, giving them a lustrous and modern look. Regular steel sheets, on the other hand, have a duller and less polished appearance. Furthermore, stainless steel sheets are often more expensive than regular steel sheets due to the additional manufacturing processes and the higher cost of the chromium alloy. However, the enhanced corrosion resistance and durability provided by stainless steel sheets can often justify the higher cost in various applications. In summary, stainless steel sheets differ from regular steel sheets in terms of their composition, properties, appearance, and cost. Stainless steel sheets offer superior corrosion resistance, heat resistance, and a visually appealing surface, making them ideal for specific applications where these attributes are required. Regular steel sheets, on the other hand, are more affordable but lack the unique properties of stainless steel.

- Q: What are the properties of stainless steel sheets?

- Stainless steel sheets possess various properties that make them highly desirable in numerous industries and applications. Firstly, stainless steel sheets exhibit excellent corrosion resistance, making them resistant to rust and staining. This property is primarily due to the presence of chromium in the alloy, which forms a protective oxide layer on the surface, preventing the material from corroding. Additionally, stainless steel sheets are known for their high strength and durability. They have a high tensile strength, allowing them to withstand heavy loads and resist deformation. This strength makes stainless steel sheets suitable for applications that require structural integrity and longevity, such as in construction, automotive, and aerospace industries. Another important property of stainless steel sheets is their heat and fire resistance. They can withstand high temperatures without losing their structural integrity or strength. This makes them ideal for applications that involve exposure to extreme heat, such as in commercial kitchens and industrial furnaces. Furthermore, stainless steel sheets are hygienic and easy to clean, making them suitable for applications in the food and medical industries. Their non-porous surface prevents the growth of bacteria, making them a reliable choice for food processing equipment, surgical instruments, and medical devices. Stainless steel sheets also have an attractive appearance, with a smooth, reflective surface that can be easily maintained. This makes them aesthetically pleasing and suitable for architectural and decorative applications, such as in building facades, interior design, and furniture manufacturing. Lastly, stainless steel sheets are highly versatile and can be easily formed, welded, and fabricated into various shapes and sizes. This flexibility allows for customization and adaptation to specific project requirements, offering designers and engineers a wide range of possibilities. In summary, the properties of stainless steel sheets include corrosion resistance, high strength and durability, heat and fire resistance, hygiene, ease of cleaning, attractive appearance, and versatility. These properties make stainless steel sheets a popular choice across numerous industries, ensuring their widespread use in a vast array of applications.

- Q: Are stainless steel sheets resistant to staining?

- Yes, stainless steel sheets are highly resistant to staining. This is because stainless steel contains a high percentage of chromium, which forms a protective layer on the surface of the metal. This layer, known as the passive layer, prevents the steel from reacting with oxygen and moisture in the environment, making it resistant to rust and corrosion. Additionally, the smooth and non-porous surface of stainless steel makes it difficult for stains to penetrate and adhere to the material. While stainless steel sheets may still show some signs of staining over time, they can be easily cleaned and restored to their original appearance with minimal effort. Overall, stainless steel sheets are a popular choice for applications where stain resistance is important, such as in kitchens, hospitals, and industrial settings.

Send your message to us

Stainless Steel Sheet 2B Surface Treatment 4mmx1240mmx2440mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords