Stainless Steel Sheet 304L with Mill Test Certificate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet in china alibaba

Product Description

Stainless steel sheet Detailed introduction

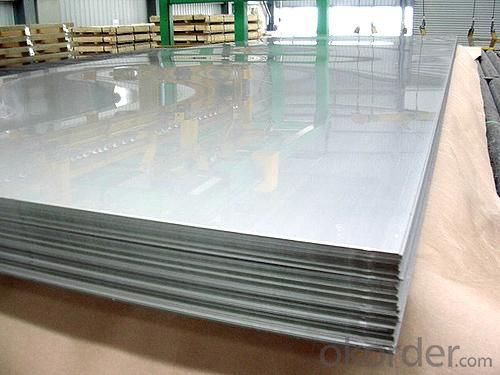

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Application :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Can stainless steel sheets be used for decorative purposes?

- Yes, stainless steel sheets can definitely be used for decorative purposes. Stainless steel is known for its sleek and modern appearance, making it a popular choice for various decorative applications. It is often used in interior design, architecture, and even art installations. Stainless steel sheets can be customized to create unique patterns, textures, and finishes, making them suitable for creating eye-catching and visually appealing decorative elements. Additionally, stainless steel is highly durable, corrosion-resistant, and easy to maintain, making it a practical choice for both indoor and outdoor decorative applications.

- Q: Can stainless steel sheets be used in food processing or medical applications?

- Yes, stainless steel sheets can be used in food processing and medical applications. Stainless steel is highly resistant to corrosion and is easy to clean, making it suitable for use in environments that require strict hygiene standards such as food processing plants and medical facilities. It is also non-reactive with food and medical substances, ensuring the safety and quality of the products being processed or treated.

- Q: How do I select the appropriate thickness for stainless steel sheets?

- When selecting the appropriate thickness for stainless steel sheets, there are a few factors to consider. First and foremost, you should determine the specific application or purpose for which the stainless steel sheets will be used. If you are looking for stainless steel sheets for decorative purposes, such as in interior design or architectural projects, a thinner gauge may be suitable. Thinner gauges, typically ranging from 26 to 30 gauge, are more flexible and easier to shape, making them ideal for intricate designs or curved surfaces. On the other hand, if you require stainless steel sheets for structural or industrial purposes, a thicker gauge would be more appropriate. Thicker gauges, generally ranging from 18 to 20 gauge, offer increased strength and durability, making them suitable for heavy-duty applications, such as construction, automotive, or manufacturing. Additionally, it is crucial to consider the intended use of the stainless steel sheets. If they will be subjected to high levels of wear and tear, exposure to harsh environments, or heavy loads, it is advisable to opt for a thicker gauge to ensure the sheets can withstand these conditions without compromising their integrity. Lastly, budgetary constraints may also play a role in determining the appropriate thickness. Thicker gauges tend to be more expensive due to the higher amount of material required. Therefore, it is important to strike a balance between the required strength and the available budget. In summary, when selecting the appropriate thickness for stainless steel sheets, consider the intended application, the required strength and durability, and any budget constraints. By taking these factors into account, you can choose the most suitable thickness that will meet your specific needs.

- Q: What is the price range of stainless steel sheets?

- The price range of stainless steel sheets can vary depending on various factors such as the grade of stainless steel, the thickness of the sheet, the size, and any additional finishes or coatings that may be applied. Generally, the price range for stainless steel sheets can start from around $20 per sheet for smaller sizes and standard grades, and can go up to several hundred dollars per sheet for larger sizes, higher grades, and specialized finishes. It is important to note that prices can also vary based on the supplier and market conditions, so it is advisable to compare prices from different sources to get the best deal.

- Q: Can stainless steel sheets be used in medical applications?

- Yes, stainless steel sheets can be used in medical applications. Stainless steel is a popular choice in the medical field due to its excellent corrosion resistance, durability, and ease of sterilization. It is widely used in medical devices, surgical instruments, and implantable components due to its ability to withstand harsh sterilization processes such as autoclaving, which is crucial for maintaining cleanliness and preventing infections. Additionally, stainless steel is biocompatible, meaning it does not react with the body's tissues and does not cause any harm or adverse reactions. Overall, stainless steel sheets are a reliable and versatile material for various medical applications.

- Q: 304 stainless steel has several advantages, a few big advantages, the more concrete the better

- 304 stainless steel has excellent stainless steel corrosion resistance and better intergranular corrosion resistance. The oxidizing acid, in the experiments: the concentration of more than 65% of boiling temperature following nitrate, 304 stainless steel has high corrosion resistance. Alkaline solution and most organic acids and inorganic acids also have good corrosion resistance.

- Q: Can stainless steel sheets be used for outdoor signage?

- Indeed, outdoor signage can be made using stainless steel sheets. This material, known for its durability and resistance to corrosion, remains unscathed in challenging weather conditions while preserving its visual appeal. Its widespread use in outdoor signage can be attributed to its ability to withstand rust, fading, and harm caused by sunlight, rain, snow, and other environmental factors. Moreover, stainless steel sheets can be personalized with different finishes like brushed or polished, enhancing their aesthetic allure and making them suitable for any outdoor signage requirement.

- Q: What are the different types of finishes available for stainless steel sheets?

- There are several different types of finishes available for stainless steel sheets, each offering its own unique appearance and level of protection. Some of the most common finishes include: 1. No. 1 Finish: This is a dull, rough, and non-reflective finish that is achieved by hot rolling the stainless steel sheet. It is commonly used for industrial applications where appearance is not a primary concern. 2. No. 2B Finish: This finish is a smooth, reflective surface achieved by cold rolling the stainless steel sheet and then annealing it in a controlled atmosphere. It is widely used in applications that require a visually appealing finish, such as kitchen appliances and decorative trim. 3. No. 4 Finish: Also known as brushed or satin finish, this is achieved by applying a series of abrasive grits to the surface of the stainless steel sheet. It creates a uniform, linear grain pattern that is commonly used for architectural and decorative purposes. 4. No. 8 Finish: This is a highly reflective finish that is achieved by polishing the stainless steel sheet to a mirror-like appearance. It is often used in applications where a sleek and sophisticated look is desired, such as in high-end architectural projects and automotive trim. 5. BA (Bright Annealed) Finish: This finish is achieved by annealing the stainless steel sheet in a controlled atmosphere and then pickling or blasting it to remove any oxide scale. It results in a smooth, bright surface that is commonly used in applications that require optimum corrosion resistance, such as medical equipment and pharmaceutical processing. 6. Hairline Finish: This finish is achieved by mechanically brushing the surface of the stainless steel sheet with fine abrasive belts. It creates a subtle, textured look that can be used for architectural and decorative purposes. 7. Embossed Finish: This finish involves imprinting a raised or recessed pattern onto the surface of the stainless steel sheet using a rolling mill or press. It adds texture and visual interest to the sheet and is often used in applications such as elevator interiors, wall cladding, and signage. These are just a few of the many finishes available for stainless steel sheets, each offering its own unique aesthetic and functional properties. The choice of finish depends on the specific application and desired appearance.

- Q: Can stainless steel sheets be used for signage or lettering?

- Yes, stainless steel sheets can be used for signage or lettering. Stainless steel is a highly durable and versatile material that is commonly used in various applications, including signage. It offers excellent resistance to corrosion, making it suitable for both indoor and outdoor use. Stainless steel sheets can be easily fabricated and cut into different shapes and sizes, allowing for the creation of customized signage and lettering designs. Additionally, stainless steel has a sleek and modern appearance, making it an attractive option for signage in commercial or professional settings. Overall, stainless steel sheets provide a reliable and long-lasting solution for signage and lettering needs.

- Q: Can stainless steel sheets be used for decorative lighting fixtures?

- Yes, stainless steel sheets can certainly be used for decorative lighting fixtures. Stainless steel is a versatile and durable material that can be shaped and formed into various designs and patterns, making it ideal for creating unique and eye-catching lighting fixtures. Its sleek and modern appearance adds a touch of elegance to any space, making it a popular choice for decorative purposes. Additionally, stainless steel is resistant to corrosion and heat, ensuring that the lighting fixtures will remain in excellent condition for a long time.

Send your message to us

Stainless Steel Sheet 304L with Mill Test Certificate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords