Stainless Steel plate 309S with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/310S/309S/316L/316Ti/316/321,410/420/430/444/443/409L, and 904L.

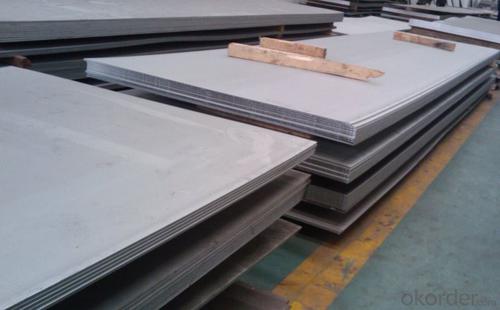

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

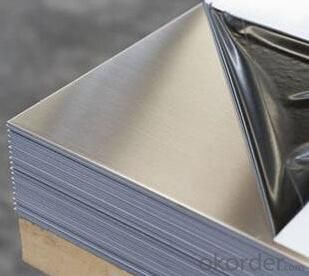

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

1. What's the quality?

very fine

2. How long get reply?

within 24 hours

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Are stainless steel sheets resistant to stress corrosion cracking?

- Yes, stainless steel sheets are generally resistant to stress corrosion cracking due to their high levels of chromium and nickel, which create a protective oxide layer on the surface. This layer prevents the initiation and propagation of corrosion cracks under tensile stress.

- Q: What type of welding rod is used for 304 stainless steel plate welding?

- The selection of reference electrode parent material, selection and composition of base metal electrode in the same or similar; owing to the great influence of carbon content on corrosion resistance of stainless steel, stainless steel weld metal carbon content is higher than that of base material.

- Q: How do stainless steel sheets resist corrosion?

- Stainless steel sheets resist corrosion due to their unique composition and protective oxide layer. Stainless steel is made up of iron, chromium, and other alloying elements such as nickel and molybdenum. The presence of chromium in stainless steel is crucial for its corrosion resistance. When exposed to oxygen, chromium forms a thin and invisible oxide layer on the surface of the stainless steel, known as the passive layer. This passive layer acts as a barrier that prevents oxygen and moisture from reaching the underlying metal, thus protecting it from corrosion. It is this layer that gives stainless steel its name, as it remains "stainless" or free from rust and corrosion. The chromium oxide layer is self-repairing and can reform if damaged or scratched, ensuring the continued protection of the stainless steel. This property allows stainless steel sheets to be used in various environments, including those with high humidity, exposure to chemicals, and even saltwater. Additionally, the alloying elements like nickel and molybdenum enhance the corrosion resistance of stainless steel. Nickel increases the stability and strength of the passive layer, while molybdenum improves resistance to pitting and crevice corrosion. Furthermore, stainless steel sheets can be further protected against corrosion through surface finishes, such as polishing or passivation. These processes remove any contaminants or impurities from the surface and promote the formation of a more robust and uniform passive layer. Overall, the combination of chromium, other alloying elements, and the protective oxide layer make stainless steel sheets highly resistant to corrosion, providing durability and longevity in various applications.

- Q: How do I install stainless steel sheets?

- To install stainless steel sheets, start by measuring and marking the area where the sheets will be installed. Next, ensure the surface is clean and free from dust or debris. Apply a strong adhesive or use screws to secure the sheets to the surface, making sure they are aligned properly. If needed, cut the sheets to fit using appropriate tools such as a metal shear or circular saw with a metal-cutting blade. Finally, ensure all edges and seams are properly sealed to prevent water or moisture infiltration.

- Q: Can stainless steel sheets be used for elevator ceiling panels?

- Yes, stainless steel sheets can be used for elevator ceiling panels. Stainless steel is a durable and visually appealing material that is commonly used in elevator construction, including for ceiling panels. It provides a sleek and modern aesthetic, while also being easy to clean and maintain.

- Q: Inspection method for stainless steel welding

- The position of the welding is measured by hand, beat, shake, push and push. The sensing effect of the component is tested. The welding should be firm and reliable, and the strength of each component is required to meet the requirements of the strength of each component. Not false welding, weld and weld loose crack,

- Q: Can stainless steel sheets be used for electromagnetic compatibility?

- Yes, stainless steel sheets can be used for electromagnetic compatibility. Stainless steel is a highly conductive material that can effectively shield against electromagnetic interference (EMI) and radio frequency interference (RFI). It can be used to create enclosures or shielding to protect sensitive electronic devices from external electromagnetic fields.

- Q: Can stainless steel sheets be used for elevator handrails or grab bars?

- Yes, stainless steel sheets can be used for elevator handrails or grab bars. Stainless steel is a common material used for these applications due to its durability, corrosion resistance, and aesthetic appeal. It is able to withstand heavy use and provides a secure grip, making it suitable for elevator handrails and grab bars.

- Q: What are the benefits of using embossed stainless steel sheets?

- Embossed stainless steel sheets offer several benefits. Firstly, they provide a highly durable and long-lasting solution due to the strength and corrosion resistance of stainless steel. Additionally, the embossed pattern adds a unique aesthetic appeal, enhancing the overall look and feel of any space. Furthermore, the embossing helps to hide scratches and fingerprints, making the surface more forgiving and easier to maintain. Lastly, the texture created by embossing adds grip, making it suitable for applications where slip resistance is required, such as flooring or staircases.

- Q: Are stainless steel sheets resistant to acetic acid?

- Yes, stainless steel sheets are generally resistant to acetic acid. Acetic acid is a weak acid and does not cause significant corrosion or damage to stainless steel. However, prolonged exposure to highly concentrated or boiling acetic acid may cause some corrosion or staining on the surface of the stainless steel. It is important to note that the resistance of stainless steel to acetic acid can vary depending on the specific grade and composition of the stainless steel.

Send your message to us

Stainless Steel plate 309S with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords