Stainless Steel Sheet Gauge22 in Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430

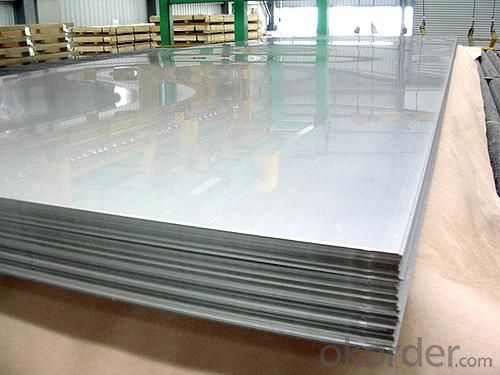

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

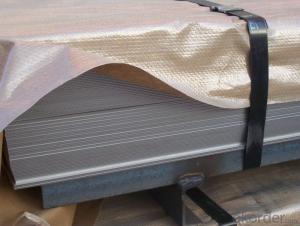

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

What are we supplying now?

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a

prelonged period. We are currently doing grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321,410/4

20/430/444/443/409L, and 904L

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Stainless steel plate glued to tiles, what glue?

- In the choice of ceramic and metal bonding, customers will take into account whether the transparent and heat-resistant properties, metal is silver white, except for a few special colors, is solid at normal temperature (except mercury). Metals generally have good ductility, electrical conductivity, heat resistance (which are related to metal is a metal crystal). Ceramic stability, acid and alkali resistance, corrosion resistance, high temperature resistance, good insulation, high hardness.

- Q: Are stainless steel sheets suitable for laser cutting?

- Indeed, laser cutting proves to be a suitable technique for cutting stainless steel sheets. By effortlessly penetrating the material, lasers facilitate the creation of precise and pristine cuts. The elevated heat resistance of stainless steel sheets further renders them ideal for laser cutting, as they endure the intense heat produced by the laser beam. Moreover, owing to their exceptional corrosion resistance, stainless steel sheets enjoy significant popularity across diverse industries. The utilization of laser cutting guarantees minimal distortion and eliminates any physical contact with the material, thereby yielding a finished product of superior quality.

- Q: What are the different finishes available for stainless steel sheets?

- There are several different finishes available for stainless steel sheets, each offering a unique look and level of protection. 1. No. 1 Finish: This is the most common and basic finish for stainless steel sheets. It is a hot-rolled finish that appears dull and rough, with visible grain lines. It is typically used for industrial applications where appearance is not a major concern. 2. No. 2B Finish: This is a bright, cold-rolled finish that is slightly reflective. It has a smooth surface with a matte finish and is commonly used for decorative purposes, such as in architectural applications or for kitchen appliances. 3. No. 4 Finish: Also known as brushed or satin finish, it has a fine polishing grit line that creates a distinctive look. This finish is often used for decorative applications, such as for elevator doors or trim, and can hide minor surface imperfections. 4. No. 8 Mirror Finish: This is the most reflective finish available for stainless steel sheets. It has a highly polished, mirror-like surface that is smooth and shiny. This finish is often used for decorative purposes, such as in architectural features or decorative trim. 5. Hairline Finish: This finish features a very fine, brushed texture that is similar to the grain of hair. It provides a subtle, elegant appearance and is commonly used for decorative and architectural applications. 6. Embossed Finish: This finish involves creating a pattern or design on the surface of the stainless steel sheet through embossing or stamping. It adds texture and visual interest to the sheet and is often used for decorative purposes. It is important to note that the availability of these finishes may vary depending on the supplier and the specific stainless steel grade being used.

- Q: What are the different types of stainless steel sheet alloys available?

- When choosing a stainless steel sheet alloy, it is crucial to take into account the particular needs of your application, as each alloy possesses its own set of advantages and disadvantages. There exists a variety of stainless steel sheet alloys from which to choose, each offering distinct properties and characteristics. Some of the most frequently encountered stainless steel sheet alloys are as follows: 1. Austenitic Stainless Steel: This is the most commonly used and versatile type of stainless steel. It lacks magnetic properties and contains substantial amounts of chromium and nickel, resulting in exceptional corrosion resistance and good formability. The 304 and 316 grades are examples of austenitic stainless steel alloys. 2. Ferritic Stainless Steel: Ferritic stainless steel possesses magnetic qualities and contains high chromium levels. It exhibits good corrosion resistance and is generally less expensive than austenitic stainless steel. The 430 and 446 grades are common examples of ferritic stainless steel alloys. 3. Martensitic Stainless Steel: Martensitic stainless steel is magnetic and contains significant amounts of carbon and chromium. It is renowned for its hardness and strength, rendering it suitable for applications requiring high wear resistance. The 410 and 420 grades are examples of martensitic stainless steel alloys. 4. Duplex Stainless Steel: Duplex stainless steel is a combination of austenitic and ferritic stainless steels, offering a balanced blend of their properties. It possesses increased strength and corrosion resistance when compared to austenitic stainless steel. Common duplex stainless steel alloys include the 2205 and 2507 grades. 5. Precipitation Hardening Stainless Steel: Precipitation hardening stainless steel alloys can be heat treated to attain high levels of strength. They contain elements such as copper, aluminum, or titanium, which form precipitates during heat treatment, leading to enhanced strength. The 17-4PH and 15-5PH grades are examples of precipitation hardening stainless steel alloys. Therefore, it is essential to carefully consider the specific requirements of your application when selecting a stainless steel sheet alloy, as each alloy possesses its own unique strengths and limitations.

- Q: 1mm how much is the thickness of the 304 stainless steel sheet a square?

- 1. PTFE/Pb mixture, 0.01-0.03mm, an abrasion resistant material that, during operation, forms a transfer film to protect the grinding shaft.2. copper powder layer, 0.20-0.35mm, to improve the bonding strength of PTFE/Pb and copper plate layer, has good bearing capacity and wear resistance. Higher thermal conductivity allows rapid transfer of heat generated during operation.3. stainless steel substrate, improve the bearing capacity and heat transfer, and have better corrosion resistance.

- Q: What are the benefits of using diamond plate stainless steel sheets in industrial flooring?

- Using diamond plate stainless steel sheets in industrial flooring offers numerous advantages. Firstly, their exceptional durability and strength make them highly resistant to wear and tear. The diamond pattern on the surface enhances their structural integrity, making them particularly suitable for protecting against damage caused by heavy machinery, equipment, and foot traffic. The stainless steel construction also ensures that the sheets are resistant to corrosion, extending their lifespan and reducing maintenance costs. Secondly, diamond plate stainless steel sheets provide superior slip resistance. The raised diamond pattern on the surface increases traction, making it safer and easier for workers to move around the industrial floor. This is especially important in environments where spills, oils, or other liquids are present, as it helps prevent slip and fall accidents and injuries. Additionally, these sheets are hygienic and easy to clean. The smooth surface and corrosion-resistant properties of stainless steel prevent dirt, grime, and bacteria buildup. This is crucial in industries such as food processing, pharmaceuticals, or healthcare, where maintaining a clean and sanitary environment is of utmost importance. Furthermore, diamond plate stainless steel sheets enhance the overall appearance of the industrial space. The diamond pattern adds a modern and industrial touch, creating a professional and visually appealing environment. Lastly, these sheets are versatile and can be easily customized to meet various industrial flooring requirements. They are available in different sizes, thicknesses, and grades, allowing for flexibility in design and installation. This adaptability makes them suitable for a wide range of applications, including factory floors, warehouses, garages, and outdoor areas. In conclusion, diamond plate stainless steel sheets offer durability, slip resistance, hygiene, aesthetic appeal, and versatility when used in industrial flooring. These advantages make them an excellent choice for ensuring a safe, long-lasting, and visually appealing flooring solution in industrial settings.

- Q: Can stainless steel sheets be painted?

- Yes, stainless steel sheets can be painted. However, it is important to properly prepare the surface to ensure good adhesion. This typically involves cleaning, sanding, and applying a primer before painting.

- Q: How do I prevent fretting corrosion on stainless steel sheets?

- To prevent fretting corrosion on stainless steel sheets, you can take several measures. Firstly, ensure that the sheets are properly cleaned and free from any contaminants before installation. This includes removing any oils, dirt, or other substances that may contribute to corrosion. Additionally, applying a corrosion-resistant coating or a protective film can act as a barrier against fretting corrosion. It is also important to avoid excessive mechanical stress or movement between the sheets, as this can lead to fretting corrosion. Finally, maintaining a dry and clean environment, with controlled humidity levels, can significantly reduce the risk of fretting corrosion on stainless steel sheets.

- Q: Are stainless steel sheets easy to install?

- Yes, stainless steel sheets are relatively easy to install. They can be easily cut to size and can be installed using various methods such as adhesive, screws, or welding, depending on the specific application. Additionally, stainless steel sheets are lightweight and flexible, making them easier to handle and install compared to other materials.

- Q: How do you prevent intergranular corrosion in stainless steel sheets?

- Intergranular corrosion in stainless steel sheets can be prevented by using materials with low carbon content, such as the 304L or 316L grades, which are more resistant to intergranular corrosion. Additionally, heat treatment processes such as solution annealing or sensitization treatment can be employed to restore the corrosion resistance of the stainless steel sheets.

Send your message to us

Stainless Steel Sheet Gauge22 in Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords