Stainless Steel Plate 201 with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

cold and hot rolled 304L mirror finish stainless steel sheet price per kg

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Material |

201/202,304/304L, 310S/309S/316L/316Ti/321,410/420/430/444/443/409L, and 904L

|

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

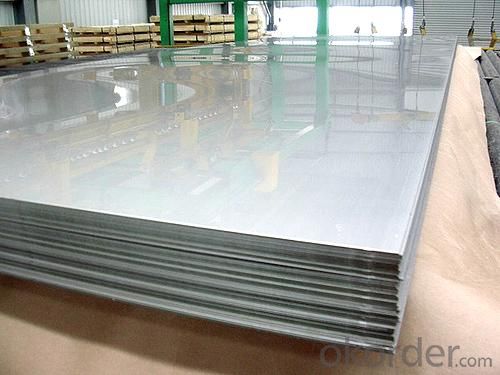

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

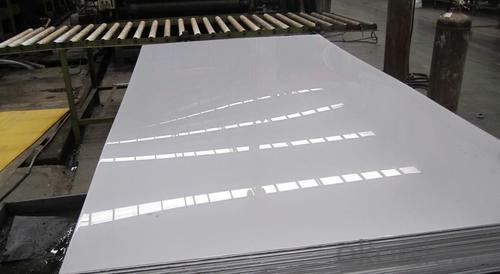

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

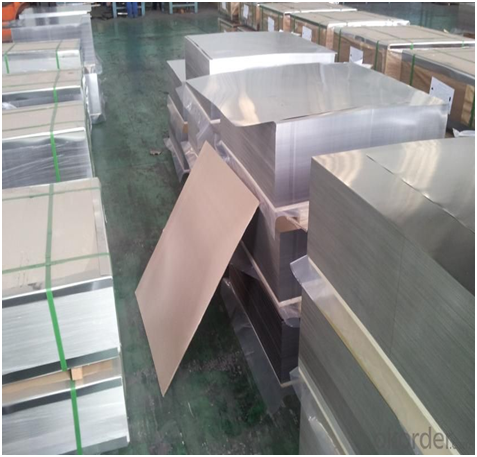

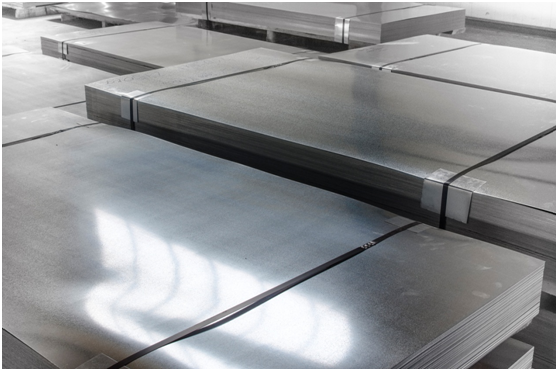

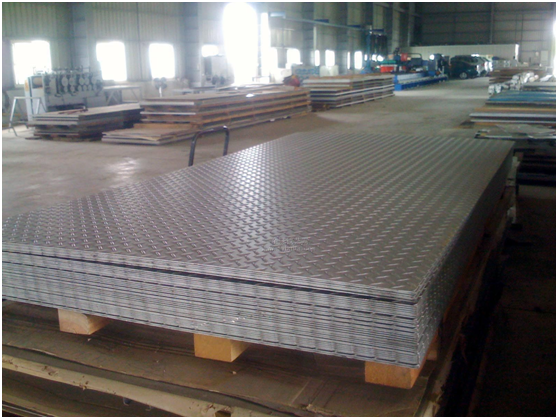

Product Details:

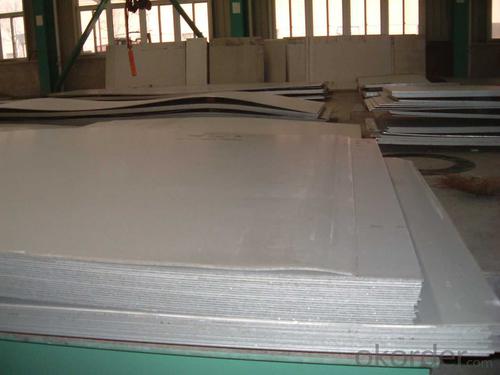

Cold Rolled and Hot Rolled:

Packaging & Shipping

Our Services

Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured.

Company Information

CNBM(China National Building Material Company)International Corporation is a state owned Enterprise.

We are listed in the fortune global 500 companies, and we are the second largest building material company in the world.

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently doing grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321,410/420/430/444/443/409L, and 904L.

FAQ

1. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

2. How long do we usually reply your request?

We always reply our customer within 24 hours.

3. What material are we supplying now?

We are specialized in producing Stainless Steel Coil, Stainless steel(plate/sheet), and duplex stainless steel for 2 decades. We are currently supplying 201/202, 304/304l, 310S/309S/316l/316Ti/321, 410/420/430/444/443/409l, and 904l.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Can stainless steel sheets be used for decorative elevator doors or panels?

- Yes, stainless steel sheets can be used for decorative elevator doors or panels. Stainless steel is a versatile material that is known for its durability, sleek appearance, and resistance to corrosion. It can be easily shaped, engraved, or finished in various ways to create visually appealing designs for elevator doors or panels. Additionally, stainless steel's hygienic properties make it a popular choice for elevator applications.

- Q: 304 how can the water stain on the surface of stainless steel plate be formed?

- If you want to scrub the proposal as soon as possible processing, water Jiyue long more difficult to wear off, if it is ferrite, also easy to rust.

- Q: How do I prevent galvanic corrosion on stainless steel sheets?

- To prevent galvanic corrosion on stainless steel sheets, you can consider a few measures. Firstly, ensure that you use compatible metals when in contact with stainless steel to avoid creating a galvanic couple. Additionally, using insulation or separating materials, such as plastic or rubber gaskets, between dissimilar metals can help prevent galvanic corrosion. Regular cleaning and maintenance of stainless steel surfaces can also mitigate the risk of corrosion. Lastly, applying protective coatings or using corrosion inhibitors can provide an extra layer of defense against galvanic corrosion on stainless steel sheets.

- Q: Are stainless steel sheets suitable for architectural mesh or screens?

- Yes, stainless steel sheets are indeed suitable for architectural mesh or screens. Stainless steel is a versatile and durable material that offers numerous advantages for architectural applications. It is resistant to corrosion, which is crucial for outdoor installations or areas with high humidity. This resistance ensures that the mesh or screens will maintain their structural integrity and aesthetic appeal over time. Additionally, stainless steel has a high strength-to-weight ratio, making it an ideal choice for architectural mesh or screens that require both durability and flexibility. It can be easily fabricated into different shapes and sizes, allowing for custom designs and variations. Stainless steel also offers a sleek and modern appearance, which enhances the overall aesthetic of architectural projects. Overall, stainless steel sheets are a reliable and suitable material for architectural mesh or screens due to their corrosion resistance, strength, versatility, and aesthetic appeal.

- Q: Are stainless steel sheets resistant to fire?

- Yes, stainless steel sheets are highly resistant to fire. Stainless steel is a type of metal alloy that contains a high percentage of chromium, which forms a protective layer of chromium oxide on the surface when exposed to air or moisture. This chromium oxide layer acts as a barrier, preventing oxygen from reaching the underlying metal and thus making stainless steel highly resistant to corrosion and fire. Stainless steel sheets have a melting point of around 2750°F (1510°C), which is significantly higher than the temperatures typically encountered in most fire scenarios. This means that stainless steel can withstand intense heat for a prolonged period without deforming or losing its structural integrity. Furthermore, stainless steel is non-combustible and does not contribute to the spread of flames. It does not release harmful gases or toxic fumes when exposed to fire, making it a safe material for use in various applications where fire resistance is crucial, such as in building construction, industrial equipment, and transportation. Due to these properties, stainless steel sheets are widely used in fire-rated structures, including fire doors, fire-rated walls, and fire-resistant enclosures. They provide an effective barrier against the heat and flames, helping to contain the fire and protect the surrounding areas. However, it is important to note that while stainless steel is highly resistant to fire, it can still be affected by extremely high temperatures or prolonged exposure to fire. In such cases, the material may experience some degree of distortion or damage. Therefore, it is essential to consider the specific fire rating requirements and consult with experts to ensure the appropriate selection and installation of stainless steel sheets in fire-resistant applications.

- Q: Can stainless steel sheets be used in the aerospace industry?

- Certainly, the aerospace industry can indeed employ stainless steel sheets. With its exceptional mechanical properties, corrosion resistance, and high strength-to-weight ratio, stainless steel is an incredibly versatile material. Hence, it finds great applicability in numerous aerospace uses. For instance, it is frequently utilized in fabricating aircraft elements like engine parts, structural frames, fuel tanks, and exhaust systems. Moreover, stainless steel sheets are also employed in manufacturing aerospace fittings, fasteners, and even interior cabin components. Thanks to its outstanding durability and ability to withstand extreme environments and temperature variations, stainless steel remains a dependable choice for the aerospace industry.

- Q: How long do stainless steel sheets last?

- Stainless steel sheets are renowned for their durability and long-lasting nature. The lifespan of these sheets can vary depending on factors like the grade and quality of the stainless steel, environmental conditions, and maintenance practices. However, with proper care and normal circumstances, stainless steel sheets can endure for many decades or even a lifetime. The longevity of stainless steel is greatly influenced by its ability to resist corrosion. This is made possible by the presence of chromium, which forms a passive layer on the surface of the material, safeguarding it from rust and corrosion. This natural protective layer enables stainless steel sheets to withstand harsh environmental conditions, including exposure to moisture, chemicals, and extreme temperatures. Moreover, the grade of stainless steel also plays a role in its lifespan. There are different grades available, such as 304, 316, and 430, each offering varying levels of corrosion resistance. Higher grades, particularly 316 stainless steel, exhibit greater resistance to corrosion and are commonly used in marine and highly corrosive environments, ensuring a longer lifespan. To maximize the lifespan of stainless steel sheets, proper maintenance is crucial. Regular cleaning with mild detergents and non-abrasive materials is necessary to eliminate dirt, grime, and contaminants that can degrade the protective layer of stainless steel. Additionally, it is important to avoid contact with harsh chemicals or abrasive materials that can scratch or damage the surface. While stainless steel sheets have an impressive lifespan, it is important to acknowledge that their durability is not limitless. Over time, factors like wear and tear, exposure to severe conditions, or improper maintenance can gradually diminish the protective layer of stainless steel and reduce its lifespan. Nonetheless, with appropriate care and maintenance, stainless steel sheets can be a cost-effective and enduring choice for various applications, including construction, automotive, and household products.

- Q: Stainless steel plate laser cutting how to charge?

- It's plasma cutting... In fact, if the process is not required, you can buy a hand grinder with cutting pieces.

- Q: Can stainless steel sheets be used for fire escapes?

- Yes, stainless steel sheets can be used for fire escapes. Stainless steel is known for its high strength, corrosion resistance, and durability, making it suitable for fire escape applications. It can withstand high temperatures and is not easily affected by fire or heat, ensuring the safety and reliability of fire escapes.

- Q: Can stainless steel sheets be used for signage or lettering?

- Yes, stainless steel sheets can be used for signage or lettering. Stainless steel is a durable and versatile material that is resistant to corrosion, making it suitable for outdoor applications. It can be cut into various shapes and sizes, allowing for customized signage and lettering designs. Additionally, stainless steel can be finished in different ways, such as brushed or polished, to achieve the desired aesthetic.

Send your message to us

Stainless Steel Plate 201 with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords