Galvanized Steel Coil with Best Quality from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

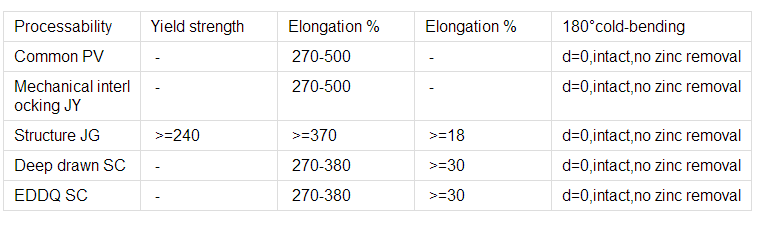

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: Are stainless steel sheets resistant to impact?

- Yes, stainless steel sheets are generally resistant to impact due to their high strength and durability. However, their level of impact resistance may vary depending on the specific grade and thickness of the stainless steel sheet.

- Q: Can stainless steel sheets be used for outdoor furniture?

- Yes, stainless steel sheets can be used for outdoor furniture. Stainless steel is a highly durable material that is resistant to rust, corrosion, and weathering. This makes it an ideal choice for outdoor furniture as it can withstand the elements and retain its appearance and structural integrity over time. Additionally, stainless steel has a sleek and modern look that can complement various outdoor design styles. Whether it's for tables, chairs, or other outdoor furniture pieces, stainless steel sheets can provide a long-lasting and visually appealing option for outdoor use.

- Q: Are stainless steel sheets resistant to oxidation?

- Yes, stainless steel sheets are resistant to oxidation. Stainless steel contains a minimum of 10.5% chromium, which forms a protective layer of chromium oxide on the surface when exposed to oxygen. This layer acts as a barrier, preventing oxygen from reaching the underlying steel and thus inhibiting oxidation. This corrosion-resistant property of stainless steel makes it an ideal choice for various applications where exposure to moisture or harsh environments is a concern. Additionally, stainless steel sheets can also contain other alloying elements such as nickel, molybdenum, and titanium, which further enhance their resistance to oxidation and corrosion.

- Q: Can stainless steel sheets be used for heat exchangers?

- Yes, stainless steel sheets can be used for heat exchangers. Stainless steel has excellent corrosion resistance, high thermal conductivity, and good mechanical properties, making it an ideal material choice for heat exchanger applications.

- Q: Can stainless steel sheets be used for food packaging equipment?

- Yes, stainless steel sheets can be used for food packaging equipment. Stainless steel is a popular material choice for food processing and packaging equipment due to its durability, corrosion resistance, and hygienic properties. It is non-reactive, which means it does not interact with the food, ensuring that the quality and taste of the food remain intact. Stainless steel sheets can be easily cleaned and sanitized, making them suitable for use in food packaging equipment where cleanliness and hygiene are of utmost importance. Additionally, stainless steel has a smooth surface, which makes it easy to handle and prevents food particles from sticking to the equipment. Overall, stainless steel sheets are a reliable and safe option for food packaging equipment.

- Q: Are stainless steel sheets suitable for hygienic applications?

- Stainless steel sheets prove to be highly suitable for applications requiring strict cleanliness and hygiene standards. Their exceptional corrosion resistance renders them ideal for environments with such requirements. The material's non-porous nature ensures it neither absorbs liquids nor harbors bacteria, thus simplifying cleaning and maintenance. Moreover, the smooth and polished surface of stainless steel discourages the accumulation of dirt, grime, and bacteria. Thanks to its durability and strength, stainless steel sheets resist scratches and dents, ensuring a long-lasting and hygienic surface. Because of these hygienic properties, stainless steel sheets find common use in the food and beverage industry, pharmaceutical industry, healthcare facilities, and laboratories.

- Q: What is the lifespan of stainless steel sheets?

- The lifespan of stainless steel sheets can vary depending on various factors such as the grade of stainless steel used, the environment it is exposed to, and the level of maintenance it receives. However, with proper care and maintenance, stainless steel sheets can last for several decades or even longer.

- Q: What drill can drill stainless steel?

- Cobalt bit, hard alloy drill bit, can drill stainless steel.

- Q: Are stainless steel sheets scratch resistant?

- Yes, stainless steel sheets are generally scratch resistant. Stainless steel is known for its durability and resistance to scratching, making it a popular choice for various applications. However, it is important to note that while stainless steel is resistant to most scratches, it is not completely scratch-proof. Deep or abrasive scratches can still occur, especially if the surface is exposed to harsh or abrasive materials. Regular maintenance and care, such as avoiding the use of abrasive cleaners or scrubbing pads, can help minimize the risk of scratches and maintain the appearance of stainless steel sheets.

- Q: 304 stainless steel plate 1*1219*C what do you mean?

- 304 stainless steel is a universal stainless steel material, antirust performance than the 200 series of stainless steel material stronger. High temperature resistance is also good, can be as high as 1000-1200 degrees. 304 stainless steel has excellent stainless steel corrosion resistance and better intergranular corrosion resistance. The oxidizing acid, in the experiments: the concentration of more than 65% of boiling temperature following nitrate, 304 stainless steel has high corrosion resistance. Alkaline solution and most organic acids and inorganic acids also have good corrosion resistance.

Send your message to us

Galvanized Steel Coil with Best Quality from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords