Diamond Plate Stainless Steel

Diamond Plate Stainless Steel Related Searches

Stainless Steel Diamond Plate Stainless Steel Plates Stainless Steel Platter Stainless Steel Dinner Plates Stainless Steel Wall Plates Stainless Steel Divided Plate Stainless Steel Charger Plates Stainless Checkered Plate Polished Aluminum Diamond Plate Anodized Aluminum Diamond Plate Diamond Checkered Plate Aluminum Diamond Plate Strips Metal Stainless Steel Colored Aluminum Diamond Plate Stainless Steel Plate For Sale Stainless Steel Stainless Thin Aluminum Diamond Plate Aluminum Black Diamond Plate Diamond Plate Aluminum Polish Stainless Steel Jewellery Stainless Steel Cover Plates Brazing Aluminum Diamond Plate Stainless Steel Jewelery Stainless Steel Camping Plates Welding Aluminum Diamond Plate Black Aluminum Diamond Plate Aluminum Diamond Plate Cooler Stick On Aluminum Diamond Plate Aluminum Diamond Plate Panels Stainless Steel Kick PlatesDiamond Plate Stainless Steel Supplier & Manufacturer from China

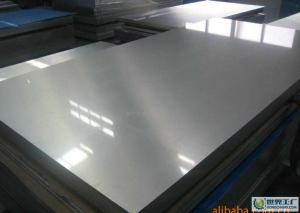

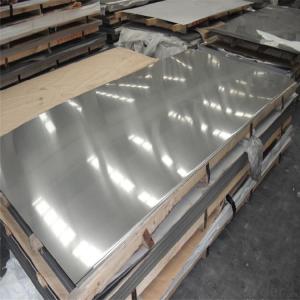

Diamond Plate Stainless Steel is a type of metal product that is known for its durability, corrosion resistance, and slip-resistant surface. This material is made from high-quality stainless steel and features a distinctive diamond pattern that adds to its aesthetic appeal and functionality. It is widely recognized for its ability to withstand harsh conditions and maintain its integrity over time, making it a popular choice for various industries.The application and usage scenarios for Diamond Plate Stainless Steel are vast, as it is suitable for both indoor and outdoor environments. Common uses include flooring, stair treads, ramps, wall cladding, and even as a decorative element in commercial and residential settings. Its slip-resistant surface makes it an ideal choice for areas where safety is a priority, such as in industrial facilities, commercial kitchens, and public spaces. Additionally, its corrosion resistance makes it perfect for marine applications and other environments where exposure to moisture and chemicals is common.

Okorder.com is a leading wholesale supplier of Diamond Plate Stainless Steel, offering a large inventory to meet the diverse needs of customers. With a commitment to quality and customer satisfaction, Okorder.com ensures that each piece of Diamond Plate Stainless Steel is manufactured to the highest standards. This allows customers to have access to a reliable and extensive selection of this versatile product, making it easier for them to find the perfect solution for their specific requirements.

Hot Products