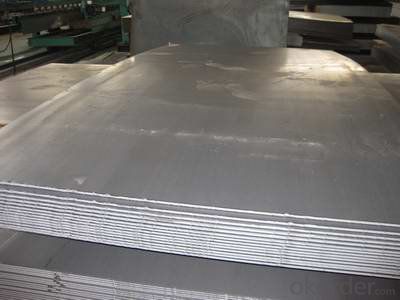

Stainless Steel Plate 201 with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

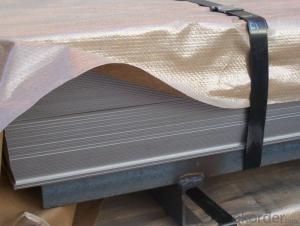

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

1. What's the quality?

very fine

2. How long get reply?

within 24 hours

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: What are the common sizes of stainless steel sheets?

- Common sizes of stainless steel sheets vary depending on the industry and application. However, there are some standard sizes that are readily available in the market. For instance, stainless steel sheets commonly come in thicknesses ranging from 0.4mm to 3.0mm. The most common widths are 1000mm, 1219mm, and 1500mm, while the most common lengths are 2000mm, 2438mm, and 3000mm. These dimensions are often referred to as 4x8 (4 feet by 8 feet), as they are the standard size for stainless steel sheets used in various construction and fabrication projects. It's worth noting that stainless steel sheets can also be custom-cut to specific dimensions based on the requirements of a particular project. This allows for greater flexibility and ensures that the sheets fit perfectly for the intended application.

- Q: What are the different types of stainless steel sheet alloys available?

- There are several types of stainless steel sheet alloys available, including austenitic, ferritic, martensitic, and duplex alloys. Each type has its own unique properties and characteristics, making them suitable for various applications.

- Q: Are stainless steel sheets safe for contact with food?

- Yes, stainless steel sheets are safe for contact with food. Stainless steel is a non-reactive and non-toxic material, making it an excellent choice for food preparation and storage. It does not leach any harmful chemicals or flavors into the food and is resistant to corrosion, ensuring hygiene and safety.

- Q: Can stainless steel sheets be used for decorative ceiling tiles?

- Indeed, decorative ceiling tiles can be created using stainless steel sheets. Renowned for its durability, resistance to corrosion, and aesthetic allure, stainless steel is a versatile material. It can be effortlessly tailored and fashioned into an assortment of designs, textures, and finishes, rendering it an exceptional option for decorative applications. By incorporating stainless steel ceiling tiles, any environment, be it residential, commercial, or industrial, can acquire a contemporary and polished appearance. Furthermore, stainless steel proves to be a practical choice in areas where cleanliness is of utmost importance, as it is facile to clean and maintain.

- Q: How long do stainless steel sheets last?

- Stainless steel sheets have an exceptionally long lifespan and can last for several decades or even a lifetime with proper care and maintenance.

- Q: Are stainless steel sheets suitable for hygienic applications?

- Yes, stainless steel sheets are highly suitable for hygienic applications. Stainless steel is corrosion-resistant, non-porous, and easy to clean, making it ideal for environments that require strict hygiene standards, such as hospitals, food processing plants, and laboratories. Additionally, stainless steel has antimicrobial properties that inhibit the growth of bacteria, further enhancing its suitability for hygienic applications.

- Q: What is the price range for stainless steel sheets?

- The cost of stainless steel sheets can fluctuate based on several factors, including the thickness, size, and grade of the stainless steel. Typically, thinner sheets begin around $30 per square foot, while thicker or higher-grade sheets can reach up to $150 per square foot. It is crucial to consider that market conditions and supplier pricing policies may also impact prices. Thus, it is advisable to compare prices from various suppliers before finalizing a purchase.

- Q: Are stainless steel sheets suitable for decorative purposes?

- Yes, stainless steel sheets are suitable for decorative purposes. Stainless steel has a sleek and modern appearance that adds a touch of elegance and sophistication to any space. Its smooth and reflective surface creates a visually pleasing aesthetic that enhances the overall look and feel of a room. Additionally, stainless steel is highly durable and resistant to corrosion, making it a long-lasting choice for decorative applications. The versatility of stainless steel sheets allows them to be used in various decorative forms, such as wall panels, backsplashes, countertops, and even furniture. Whether in residential or commercial settings, stainless steel sheets can be utilized to create stunning and eye-catching decorative elements that complement any interior design style.

- Q: What's the cheapest kind of stainless steel plate? What's the model and how much is it?

- The cheapest is 201, the price is relative to the thickness

- Q: Can stainless steel sheets be used for water filtration systems?

- Yes, stainless steel sheets can be used for water filtration systems. Stainless steel is corrosion-resistant, durable, and can withstand high temperatures, making it suitable for water filtration applications. Additionally, its smooth surface helps to prevent the growth of bacteria and biofilm, ensuring clean and safe water filtration.

Send your message to us

Stainless Steel Plate 201 with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords