Stainless Steel Plate 409L with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

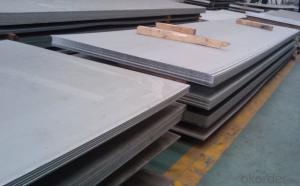

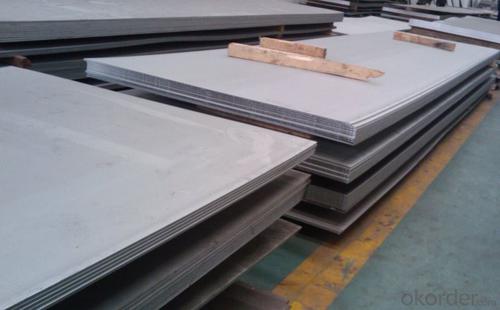

Stainless Steel Plate 409L with Surface Treatment

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Material |

201/202,304/304L, 310S/309S/316L/316Ti/321,410/420/430/444/443/409L, and 904L

|

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

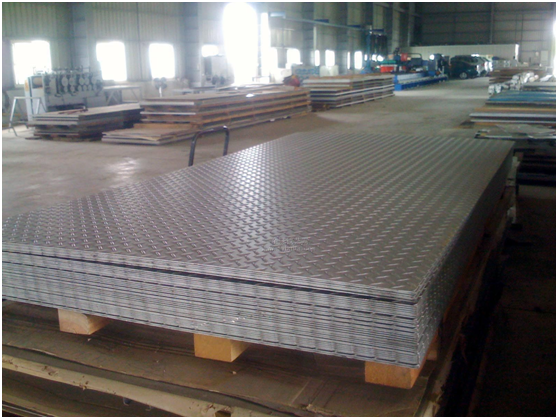

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

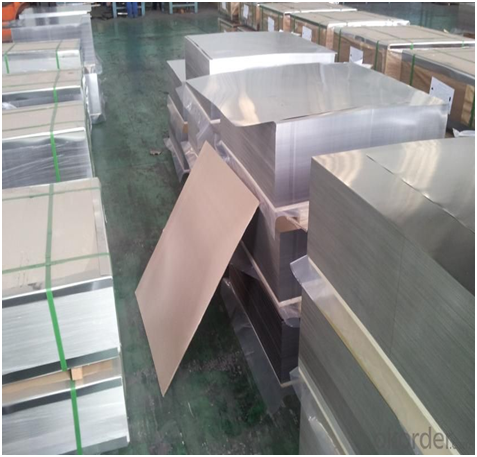

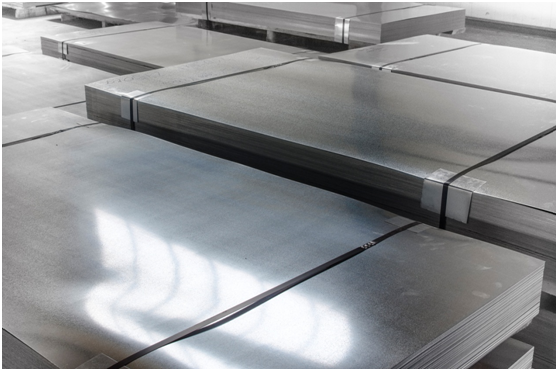

Product Details:

Cold Rolled and Hot Rolled:

Packaging & Shipping

Our Services

Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured.

Company Information

CNBM(China National Building Material Company)International Corporation is a state owned Enterprise.

We are listed in the fortune global 500 companies, and we are the second largest building material company in the world.

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently doing grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321,410/420/430/444/443/409L, and 904L.

FAQ

1. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

2. How long do we usually reply your request?

We always reply our customer within 24 hours.

3. What material are we supplying now?

We are specialized in producing Stainless Steel Coil, Stainless steel(plate/sheet), and duplex stainless steel for 2 decades. We are currently supplying 201/202, 304/304l, 310S/309S/316l/316Ti/321, 410/420/430/444/443/409l, and 904l.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Can stainless steel sheets be used for column covers?

- Yes, stainless steel sheets can be used for column covers. Stainless steel is a durable and corrosion-resistant material, making it suitable for exterior applications. It provides an attractive and modern finish that can enhance the aesthetic appeal of a building. Stainless steel sheets can be easily fabricated and installed to fit around columns, creating a sleek and seamless appearance. Additionally, stainless steel is low maintenance and easy to clean, making it a practical choice for column covers that are exposed to the elements.

- Q: Are stainless steel sheets suitable for architectural mesh or screens?

- Yes, stainless steel sheets are indeed suitable for architectural mesh or screens. Stainless steel is a versatile and durable material that offers numerous advantages for architectural applications. It is resistant to corrosion, which is crucial for outdoor installations or areas with high humidity. This resistance ensures that the mesh or screens will maintain their structural integrity and aesthetic appeal over time. Additionally, stainless steel has a high strength-to-weight ratio, making it an ideal choice for architectural mesh or screens that require both durability and flexibility. It can be easily fabricated into different shapes and sizes, allowing for custom designs and variations. Stainless steel also offers a sleek and modern appearance, which enhances the overall aesthetic of architectural projects. Overall, stainless steel sheets are a reliable and suitable material for architectural mesh or screens due to their corrosion resistance, strength, versatility, and aesthetic appeal.

- Q: Can stainless steel sheets be cut or shaped easily?

- Yes, stainless steel sheets can be cut or shaped easily. Stainless steel is known for its excellent machinability and workability, making it relatively easy to cut, shape, and form into desired shapes or sizes with the right tools and techniques.

- Q: Can stainless steel sheets be used in food processing industries?

- Yes, stainless steel sheets are commonly used in food processing industries for various applications. Stainless steel is highly resistant to corrosion, making it ideal for use in environments where food is processed, stored, or handled. It is hygienic, easy to clean, and does not react with the food, ensuring that the quality and safety of the food are maintained. Stainless steel sheets are used for making food preparation surfaces, worktables, countertops, sinks, shelves, storage tanks, and equipment like mixers, conveyors, and ovens. Additionally, stainless steel sheets are durable and can withstand high temperatures, making them suitable for a wide range of food processing operations.

- Q: Can stainless steel sheets be bent or formed without cracking?

- Stainless steel sheets possess the ability to be bent or formed without any occurrence of cracking. The remarkable formability and ductility of stainless steel enables effortless bending, shaping, or forming into diverse configurations. Nevertheless, the degree to which stainless steel can be bent sans cracking hinges on various factors, such as the stainless steel's grade and thickness, the type of bending or forming technique employed, as well as the equipment and methodologies utilized. To avoid cracking, it is crucial to utilize appropriate bending tools, employ gradual and consistent pressure, and refrain from exerting excessive force or sharp bends. Additionally, enhancing the formability of stainless steel sheets and minimizing the risk of cracking during bending or forming procedures can be achieved by preheating or annealing them.

- Q: How do you form stainless steel sheets into different shapes?

- Different shapes can be achieved with stainless steel sheets by employing various processes, including bending, rolling, and welding. The choice of method depends on the desired shape and the thickness of the sheet. To form stainless steel sheets into shapes like cylinders or boxes, bending is commonly used. This involves clamping the sheet between a punch and a die and applying force to create the desired bend. By adjusting the pressure and the distance between the punch and die, the angle and radius of the bend can be controlled. Rolling is another technique used to form stainless steel sheets into curved or cylindrical shapes. This process entails passing the sheet through a series of rollers, which gradually bend the material into the desired shape. The diameter and curvature of the final shape can be altered by changing the spacing and alignment of the rollers. For more complex shapes, welding is often combined with bending or rolling. Multiple stainless steel sheets are joined together using heat and pressure to create the desired form. This enables the creation of intricate shapes, such as cones or irregular geometries. In addition to these methods, specialized equipment like hydraulic presses or hydroforming can be employed to shape stainless steel sheets. These techniques involve applying high pressure or fluid pressure to the sheet, resulting in deformation and the desired shape. It is crucial to note that forming stainless steel sheets necessitates skilled operators and precise machinery to ensure accuracy and quality. Moreover, the properties of the stainless steel, such as thickness and composition, can also impact the feasibility and success of the forming process.

- Q: Can stainless steel sheets be welded?

- Yes, stainless steel sheets can be welded. Stainless steel is a versatile material that can be welded using various welding techniques such as TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, or spot welding. However, the specific type of stainless steel and the thickness of the sheet will determine the most suitable welding method. It is important to ensure proper surface preparation, cleanliness, and the use of appropriate filler materials to achieve a strong and durable weld. Additionally, stainless steel has a higher thermal conductivity compared to other metals, so it may require more precise control of heat input during the welding process to prevent distortion or warping of the sheet.

- Q: Are stainless steel sheets suitable for architectural facades?

- Yes, stainless steel sheets are suitable for architectural facades. They offer durability, corrosion resistance, and a sleek modern look that complements various architectural styles. Stainless steel sheets can withstand harsh weather conditions and require minimal maintenance, making them an excellent choice for long-lasting and visually appealing facades.

- Q: Do stainless steel sheets require any special handling during installation?

- Yes, stainless steel sheets require special handling during installation to ensure their proper installation and to prevent damage. Some important considerations include using proper lifting equipment, ensuring a clean and dry surface, avoiding contact with other metals to prevent galvanic corrosion, and following the manufacturer's guidelines for installation and maintenance.

- Q: Can stainless steel sheets be used for fire escapes?

- Indeed, fire escapes can utilize stainless steel sheets. Stainless steel, known for its remarkable durability and resistance, exhibits the ability to endure elevated temperatures and retain its structural integrity when confronted with fire. This material, free from combustible properties, abstains from emitting hazardous gases when subjected to heat, thereby establishing itself as a secure option for constructing fire escapes. Moreover, the corrosion resistance inherent in stainless steel guarantees the longevity and dependability of the fire escape system. Ultimately, stainless steel sheets emerge as an exceptional selection for fire escapes due to their robustness, fire resistance, and durability.

Send your message to us

Stainless Steel Plate 409L with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords