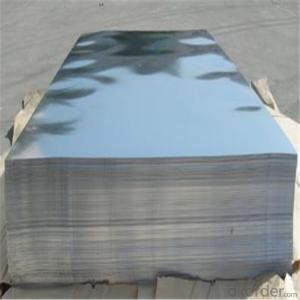

Stainless Steel Plates

Stainless Steel Plates Related Searches

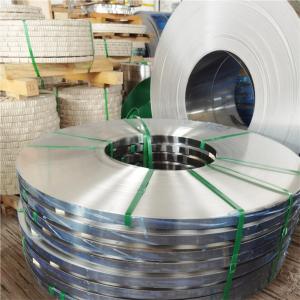

Stainless Steel Wall Plates Stainless Steel Cover Plates Stainless Steel Dinner Plates Stainless Steel Platter Stainless Steel Charger Plates Stainless Steel Camping Plates Stainless Steel Diamond Plate Stainless Checkered Plate Stainless Steel Switch Plates Stainless Steel Kick Plates Stainless Steel Kids Plates Stainless Steel Metals Diamond Plate Stainless Steel Stainless Steel Materials Stainless Steel Pipes Stainless Steel Plate For Sale Stainless Steel Shelves Stainless Steel Wires Stainless Steel Apliances Stainless Steel Tape Stainless Steel Grates Stainless Steel Toddler Plates Stainless Steel Elements Stainless Steel Tiles Stainless Steel Furniture Stainless Steel Enclosures Stainless Steel Kitchens Stainless Steel Divided Plate 1 4 Stainless Steel Plate Stainless Steel StripsStainless Steel Plates Supplier & Manufacturer from China

Stainless Steel Plates are a type of metal sheet material known for their corrosion resistance, durability, and strength. These plates are made from stainless steel alloys, which contain a minimum of 10.5% chromium, providing them with their characteristic corrosion resistance. They come in various grades, thicknesses, and finishes, making them suitable for a wide range of applications.Stainless Steel Plates find extensive use in industries such as construction, automotive, aerospace, and food processing due to their ability to withstand harsh environments and maintain their integrity over time. They are commonly utilized in the manufacturing of kitchen appliances, architectural structures, and industrial equipment, where their resistance to rust and ease of cleaning are highly valued. Additionally, their aesthetic appeal makes them a popular choice for decorative purposes and in the production of various consumer goods.

Okorder.com is a leading wholesale supplier of Stainless Steel Plates, offering a vast inventory of high-quality products to cater to the diverse needs of clients worldwide. With a commitment to excellence, they ensure that their stainless steel plates meet the highest industry standards and are available at competitive prices. This makes Okorder.com an ideal partner for businesses looking to source stainless steel plates for their projects and applications.

Hot Products