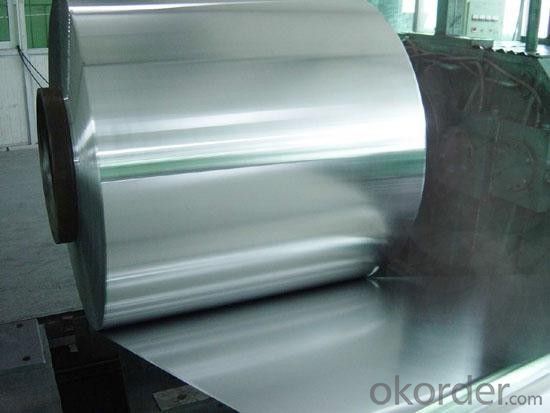

Stainless Steel Sheet and Plate with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of stainless steel

304 stainless Steel Plate

stainless steel plate,steel sheet,steel plate

Standard: ASTM,GB,DIN,JIS,ISO,EN,etc.

TISCO stainless Steel Plate 304/NO.1 finished

stainless steel plate,steel sheet,steel plate

Standard: ASTM,GB,DIN,JIS,ISO,EN,etc.

Delivery short and low cost advantage.

Description of stainless steel:

stainless steel plate,hot rolled stainless steel plate,cold rolled stainless steel plate,stainless steel sheet,steel sheet,sheet

Material of stainless steel:

304,304L,309S,310S,316,316L,316Ti,317L,317L,321,347H,409,409L,410S,420,430,201,202,etc.

Thickness of stainless steel:

From 0.3mm to 100mm

Width of stainless steel:

1000mm,1219mm,1250mm,1500mm,1800mm,2200mm,2500mm or as your requirement

Length of stainless steel:

2000mm,2438mm,2500mm,6000mm,6096mm or as your requirement

Application of stainless steel:

Stainless steel plate applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. Our company has cooperative relation between the domestic agents. Stainless steel plate can be made accordingto the customers requirements. Fasten delivery. Quality assured.Welcome to order more.

Contacts

If you have any question,please feel free to contact us.

- Q: Can stainless steel sheets be used for roofing?

- Yes, stainless steel sheets can be used for roofing. Stainless steel is a durable and long-lasting material that is resistant to corrosion, rust, and weathering, making it an excellent choice for roofing applications. It is commonly used in industrial, commercial, and residential roofing projects. Stainless steel sheets offer high strength and are able to withstand extreme weather conditions, including heavy rain, snow, and wind. Additionally, stainless steel is fire-resistant and does not warp or crack, providing a reliable and secure roofing solution. However, it is important to note that stainless steel roofing materials can be more expensive than other roofing options, so cost considerations should be taken into account.

- Q: What is the price range of stainless steel sheets?

- The price of stainless steel sheets can fluctuate due to a variety of factors, including the grade, sheet thickness, size, and any additional finishes or coatings. Typically, the price range for stainless steel sheets begins at approximately $20 per sheet for smaller sizes and standard grades. However, for larger sizes, higher grades, and specialized finishes, the price can escalate to several hundred dollars per sheet. It is worth mentioning that prices can also differ depending on the supplier and market conditions. Therefore, it is advisable to compare prices from multiple sources in order to secure the most favorable deal.

- Q: What are the different types of stainless steel sheet patterns available?

- There are several different types of stainless steel sheet patterns available, each with its own unique design and characteristics. Some of the most common patterns include: 1. Plain or smooth: This is the most basic and common pattern, featuring a smooth and simple surface without any visible texture or design. 2. Brushed or satin: This pattern is achieved by brushing the surface of the stainless steel sheet with a fine grit abrasive, creating a consistent directional grain. It provides a subtle and elegant look. 3. Diamond or quilted: This pattern features a raised diamond-shaped design on the surface of the stainless steel sheet, providing enhanced traction and slip resistance. It is commonly used for flooring, stairs, and industrial applications. 4. Linen: This pattern resembles the texture of linen fabric, with a series of parallel lines etched onto the surface of the stainless steel sheet. It adds a unique visual appeal and can be used in various applications, including interior design and architectural projects. 5. Perforated: This pattern consists of a series of small holes or perforations punched into the stainless steel sheet, creating a visually interesting and functional design. It is commonly used in applications that require ventilation or filtration. 6. Checker or tread: This pattern features a raised checkerboard design on the surface of the stainless steel sheet, providing a non-slip surface. It is commonly used for flooring, stairs, and transportation equipment. These are just a few examples of the different types of stainless steel sheet patterns available. Each pattern offers a different aesthetic and functional value, allowing for versatile use in a wide range of applications.

- Q: Can stainless steel sheets be used for elevator buttons?

- Yes, stainless steel sheets can be used for elevator buttons. Stainless steel is often chosen for its durability, resistance to corrosion, and sleek appearance, making it a suitable material for elevator buttons that are frequently touched and exposed to various environmental conditions.

- Q: What are the different types of etched patterns available for stainless steel sheets?

- Stainless steel sheets come in a range of etched patterns, each with its own distinctive and visually appealing design. Some popular options include: 1. The Diamond Pattern: This classic and elegant design features small diamond-shaped indentations etched onto the stainless steel surface. It is commonly used in architectural applications. 2. The Checkerboard Pattern: Resembling a checkered board, this pattern adds a modern and geometric touch to stainless steel sheets. It is often utilized in interior design and decorative settings. 3. The Floral Pattern: Incorporating floral designs etched onto the stainless steel sheet, this pattern brings an element of elegance and sophistication. It is commonly seen in luxury home decor and jewelry. 4. The Geometric Pattern: Offering a contemporary and artistic look, this pattern includes various geometric shapes etched onto the stainless steel sheet. It is suitable for both modern and traditional settings. 5. The Wave Pattern: By etching wavy lines onto the stainless steel sheet, this pattern creates a sense of movement and fluidity. It is frequently employed in architectural projects for a dynamic and visually interesting effect. 6. The Textured Pattern: With various textures like brushed, hammered, or linen finishes etched onto the stainless steel sheet, this pattern adds depth and dimension to the metal. It is ideal for interior design and decorative purposes. 7. Custom Patterns: In addition to the standard options, it is also possible to create custom patterns based on specific designs or logos. This allows for personalized and unique stainless steel sheets, often used in branding or specialty projects. Overall, the wide range of etched patterns available for stainless steel sheets provides endless possibilities for design and application. Whether for architectural, decorative, or industrial purposes, there is a pattern to suit every need and aesthetic preference.

- Q: Are stainless steel sheets suitable for architectural facades?

- Architectural facades can greatly benefit from the use of stainless steel sheets. Not only are they highly suitable, but they also offer numerous advantages in terms of their aesthetic appeal, durability, and sustainability. Firstly, stainless steel sheets possess an inherent visual appeal that can greatly enhance the overall look of any building. With its sleek and modern appearance, stainless steel can effortlessly elevate the design aesthetic. Furthermore, architects have the freedom to choose from a variety of finishes such as brushed, mirrored, or patterned, allowing them to achieve their desired look and feel. Moreover, stainless steel is highly resistant to corrosion, making it an ideal choice for outdoor applications. It can withstand exposure to harsh weather conditions, pollution, and other environmental factors without deteriorating. This remarkable resistance to corrosion also means that stainless steel requires minimal maintenance, resulting in reduced long-term costs and efforts associated with facade upkeep. In terms of strength and durability, stainless steel sheets excel. They can withstand impact, making them suitable for high-traffic areas or buildings located in regions prone to severe weather events. Additionally, stainless steel is resistant to staining, scratching, and fading, ensuring that the facade remains attractive and intact for an extended period. Sustainability is another significant advantage of stainless steel sheets for architectural facades. As a 100% recyclable material, stainless steel can be reused without losing its properties, making it an environmentally friendly option. Furthermore, its longevity significantly reduces the need for frequent replacements, further contributing to sustainability efforts. In conclusion, stainless steel sheets are an excellent choice for architectural facades due to their aesthetic appeal, corrosion resistance, strength, durability, and sustainability. Regardless of whether they are used in modern or traditional designs, stainless steel can provide a long-lasting and visually pleasing solution for enhancing the exterior of buildings.

- Q: Can stainless steel sheets be used for kitchen backsplashes?

- Yes, stainless steel sheets can be used for kitchen backsplashes. Stainless steel is a popular choice for backsplashes due to its durability, resistance to stains and heat, and easy maintenance. It provides a sleek and modern look to the kitchen while also protecting the walls from splatters and spills.

- Q: Can stainless steel sheets be used for elevator ceilings or floors?

- Indeed, elevator ceilings or floors can be constructed using stainless steel sheets. Stainless steel, a remarkably resilient and adaptable material, is frequently employed in diverse architectural endeavors, including the creation of elevator interiors. This material boasts a multitude of advantages, such as its resistance to corrosion, simplicity of maintenance, and its ability to lend a sleek and contemporary aesthetic. By customizing stainless steel sheets to match the precise dimensions and design requisites of elevator ceilings or floors, an elegant and practical solution is achieved. Furthermore, stainless steel seamlessly integrates with various elevator accessories, such as lighting fixtures, handrails, and buttons, facilitating a cohesive incorporation within the overall elevator design.

- Q: Are stainless steel sheets suitable for food packaging equipment?

- Yes, stainless steel sheets are suitable for food packaging equipment. Stainless steel is a popular choice for this application due to its excellent corrosion resistance, durability, and hygienic properties. It can withstand frequent cleaning and sterilization processes, ensuring food safety and maintaining the quality of packaged products. Additionally, stainless steel is non-reactive, preventing any contamination or alteration of the food during packaging. Overall, stainless steel sheets are a reliable and suitable material for food packaging equipment.

- Q: How do you prevent crevice corrosion on stainless steel sheets?

- To prevent crevice corrosion on stainless steel sheets, it is important to ensure proper cleaning and maintenance. Regularly inspect the sheets for any signs of damage or corrosion and promptly address any issues. Avoid leaving stagnant water or debris in crevices or gaps as they can promote corrosion. Applying protective coatings, such as paints or sealants, can also help prevent crevice corrosion. Additionally, using stainless steel grades that are more resistant to crevice corrosion, such as 316 or 317, can be beneficial in preventing this type of corrosion.

Send your message to us

Stainless Steel Sheet and Plate with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords