Stainless Steel Plate 321 with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Stainless Steel Plate 321 with Surface Treatment

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Material |

201/202,304/304L, 310S/309S/316L/316Ti/321,410/420/430/444/443/409L, and 904L

|

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

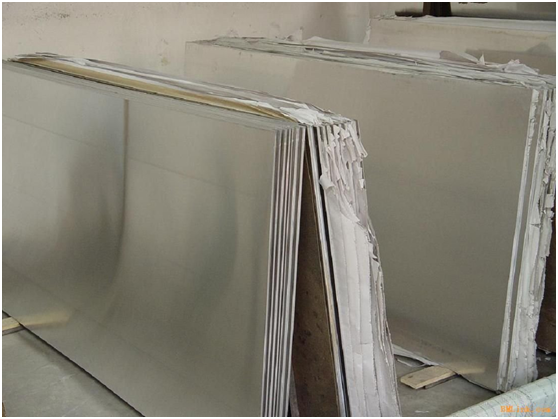

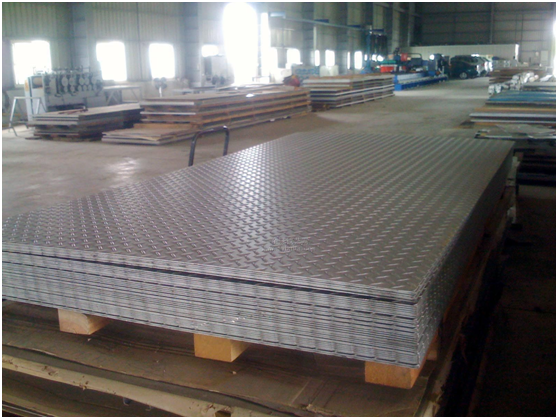

Product Details:

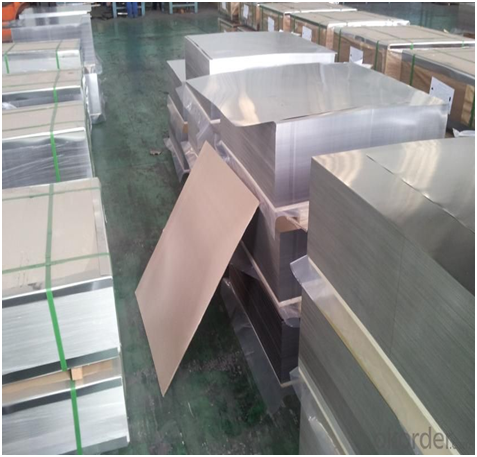

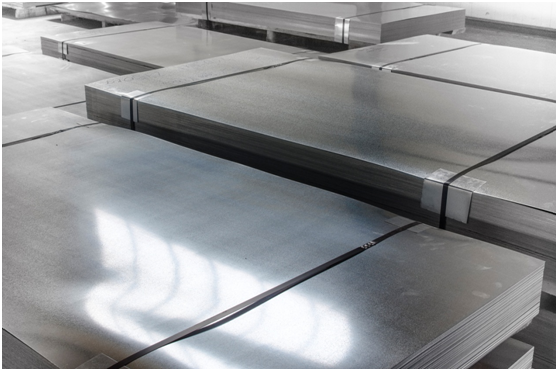

Cold Rolled and Hot Rolled:

Packaging & Shipping

Our Services

Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured.

Company Information

CNBM(China National Building Material Company)International Corporation is a state owned Enterprise.

We are listed in the fortune global 500 companies, and we are the second largest building material company in the world.

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently doing grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321,410/420/430/444/443/409L, and 904L.

FAQ

1. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

2. How long do we usually reply your request?

We always reply our customer within 24 hours.

3. What material are we supplying now?

We are specialized in producing Stainless Steel Coil, Stainless steel(plate/sheet), and duplex stainless steel for 2 decades. We are currently supplying 201/202, 304/304l, 310S/309S/316l/316Ti/321, 410/420/430/444/443/409l, and 904l.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Several processing techniques of colored stainless steel

- Sand blasting, sand blasting can be plated color, but the color of the plating and ordinary plating color difference exists, mainly due to sand blasting particles for emery. The color stainless steel sand blasting plate is made of zirconium beads through the mechanical equipment in the stainless steel plate surface, so that the surface of the board presents small beads, grainy sand surface, forming a unique decorative effect. Uses: mainly used in architectural decoration, elevator decoration, industrial decoration, facilities, decoration and other stainless steel products.

- Q: What is the standard size of a stainless steel sheet?

- The standard size of a stainless steel sheet can vary depending on the manufacturer and the specific application. However, in general, stainless steel sheets are commonly available in standard sizes of 4 feet by 8 feet (1220mm by 2440mm) or 4 feet by 10 feet (1220mm by 3050mm). These dimensions are widely used in various industries such as construction, manufacturing, and fabrication. Additionally, stainless steel sheets may also come in different thicknesses, ranging from 0.4mm to 6mm or more, depending on the intended use and requirements. It is important to note that custom sizes and dimensions can also be obtained from manufacturers for specific projects or applications that require non-standard sizes.

- Q: Can stainless steel sheets be used for outdoor railings?

- Yes, stainless steel sheets can be used for outdoor railings. Stainless steel is a popular choice for outdoor applications due to its durability and resistance to corrosion. It is able to withstand exposure to various weather conditions, such as rain, snow, and sunlight, without deteriorating or rusting. Stainless steel railings provide a sleek and modern look to outdoor spaces, while also offering strength and stability. Additionally, stainless steel is low maintenance and easy to clean, making it an ideal material for outdoor railings that may be subjected to dirt, dust, or other debris. Overall, stainless steel sheets are an excellent choice for outdoor railings, offering both aesthetic appeal and long-lasting performance.

- Q: Are stainless steel sheets suitable for chemical transport containers?

- Indeed, chemical transport containers can rely on stainless steel sheets. Renowned for its exceptional resistance to corrosion, stainless steel proves highly appropriate for chemical transportation. Its ability to withstand numerous acids, alkalis, and corrosive substances guarantees the preservation and purity of the chemicals throughout transit. Moreover, stainless steel sheets boast durability and strength, delivering structural integrity to the containers and ensuring the secure transportation of chemicals.

- Q: Can stainless steel sheets be used for elevator shafts?

- Elevator shafts can indeed utilize stainless steel sheets, as they offer durability, resistance to corrosion, and an appealing aesthetic. By employing stainless steel sheets, one can ensure a lasting and easy-to-maintain solution, as they resist rust and corrosion caused by factors like humidity, moisture, and chemicals. Moreover, stainless steel possesses strength and can withstand the weight and stress typically encountered by elevator shafts. The sleek and contemporary look of stainless steel further enhances the overall design value of the elevator shaft. Consequently, stainless steel sheets serve as a dependable and fitting material choice for constructing elevator shafts.

- Q: Can stainless steel sheets be used for kitchen countertops?

- Yes, stainless steel sheets can be used for kitchen countertops. Stainless steel is a durable and hygienic material that is resistant to stains, heat, and bacteria. It is a popular choice for kitchen countertops due to its modern aesthetic, easy maintenance, and ability to withstand heavy use.

- Q: Is stainless steel plate permitted to contact galvanized material?

- The reason why stainless steel can not be welded or contacted directly with ordinary steel is to prevent corrosion of stainless steel, not to prevent corrosion of ordinary steel.

- Q: Is there a big price difference between the SUS304 stainless steel plate and the drawing plate?

- Wire drawing is the surface of a steel processing methods, 304 and 201 steel plates can be processed drawing, the price difference is not very large, it will be more than a processing fee. The steel plate after drawing is more likely to rust than the steel plate on the 2B surface.

- Q: What are the different types of stainless steel sheet finishes for automotive applications?

- There are several different types of stainless steel sheet finishes that are commonly used in automotive applications. These finishes are designed to provide both aesthetic appeal and functional benefits for the automotive industry. 1. No. 1 Finish: This is a hot-rolled, annealed, and pickled finish that is characterized by a rough, dull appearance. It is commonly used in non-decorative applications where corrosion resistance is the primary concern. 2. No. 2B Finish: This is a bright, cold-rolled finish that is commonly used for automotive trim and decorative applications. It has a smooth surface and a moderate level of reflectivity. 3. No. 3 Finish: This is a semi-polished finish that is achieved by using progressively finer abrasives. It has a moderate level of reflectivity and is commonly used for decorative applications where a shinier appearance is desired. 4. No. 4 Finish: This is a brushed finish that is achieved by polishing the stainless steel sheet with a fine-grit abrasive. It has a consistent, linear grain pattern and a moderate level of reflectivity. It is commonly used for decorative applications such as trim and accents. 5. No. 8 Mirror Finish: This is a highly polished finish that is achieved by buffing the stainless steel sheet with a series of abrasive compounds. It has a mirror-like appearance and is commonly used for decorative applications that require a high level of reflectivity. In addition to these standard finishes, there are also specialty finishes available for automotive applications, such as embossed, patterned, or textured finishes. These finishes can provide unique design elements and enhance the overall aesthetic appeal of the vehicle. Overall, the choice of stainless steel sheet finish for automotive applications depends on the specific requirements of the project, including factors such as corrosion resistance, durability, and desired appearance.

- Q: How do you remove water spots from stainless steel sheets?

- Achieving water spot-free stainless steel sheets is simple with these steps: 1. Begin by thoroughly cleansing the surface using a mild dish soap and warm water solution. This will eliminate any dirt or grime that might contribute to the presence of water spots. 2. Rinse the sheets with fresh water and dry them completely using a soft cloth or towel. This is crucial to prevent the formation of new water spots during the cleaning procedure. 3. Subsequently, create a mixture of equal parts white vinegar and water. Immerse a clean cloth or sponge into the solution, ensuring to remove any excess liquid. 4. Gently rub the affected areas of the stainless steel sheets with the vinegar solution-soaked cloth or sponge. Make sure to follow the grain of the stainless steel in order to avoid scratching the surface. 5. Once the water spots have been rubbed, rinse the sheets with clean water and thoroughly dry them again using a soft cloth or towel. 6. If the water spots persist, you can attempt using a stainless steel cleaner or polish specifically formulated for eliminating stains and water spots. Follow the instructions provided with the cleaner and test it on a small, inconspicuous area beforehand to ensure it does not harm the stainless steel. Always remember to utilize soft materials and gentle cleaning techniques when dealing with stainless steel to prevent scratching or damaging the surface.

Send your message to us

Stainless Steel Plate 321 with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords