Stainless Steel Sheet/Plate 201 with Good Corrosion Resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 8500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Sheet/Plate 201 with Good Corrosion Resistance

Description of Stainless Steel Sheet/Plate 201 with Good Corrosion Resistance:

304 stainless steel is the most widely used in the 300 series stainless steel.

Its anti-corrosion property is stronger than the 200-series

stainless steel, but the anti-acid property is worse than 316. 304 stainless steel have a good resistance in high temperature and the

excellent corrosion resistance.

304 stainless steel is more expensive than 201, cheaper than the 316.

1. Commodity: 304 Stainless Steel

2. Technique: Cold Rolled/hot rolled Stainless Steel

3. Grade: 304 Stainless Steel

4. Type: Stainless Steel Sheet/coil

5. Finish: 2B/Ba/8K/Emboss/Etch

6. Edge: mill edge /silted edge

7.Size:1219mm*2438mm,1219mm*3048mm,or as customized

Usages of Stainless Steel Sheet/Plate 201 with Good Corrosion Resistance:

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Specifications of Stainless Steel Sheet/Plate 201 with Good Corrosion Resistance:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Surface Finish Characteristics Stainless Steel Sheet/Plate 201 with Good Corrosion Resistance:

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

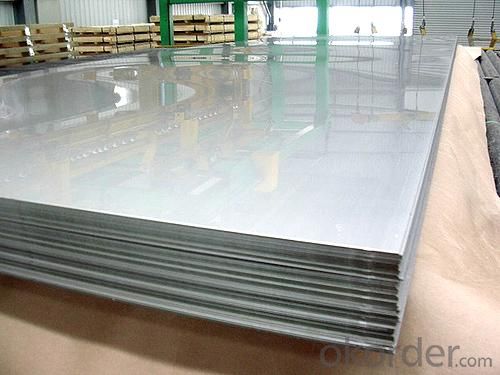

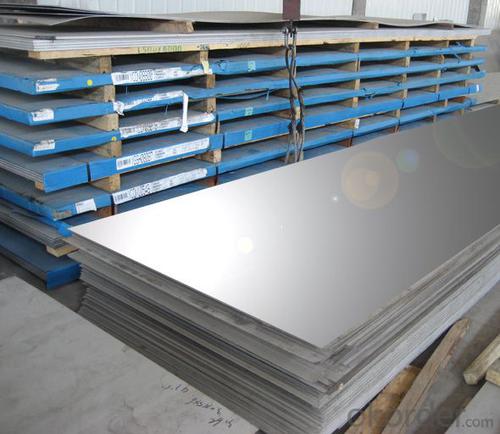

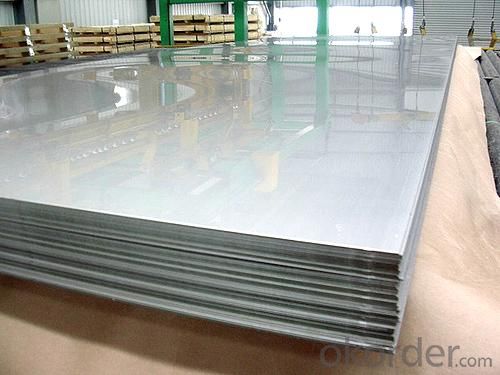

Images of Stainless Steel Sheet/Plate 201 with Good Corrosion Resistance:

Sandard Seaworth Packing(wooden packing with water proof paper):

FAQ of Stainless Steel Sheet/Plate 201 with Good Corrosion Resistance:

1. What are we supplying?

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently supplying grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321, 410/420/430/443/444/409L, and 904L.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

If you have any question about stainless steel sheets,donot forget to sending the email to Us!

You will get the competitive Price and have a very good experience about the Buying Process!

CNBM International Corporation is always your trustful friend!

- Q: Several processing techniques of colored stainless steel

- Etched series, etched images, visible pictures. After etching, the color or color can be etched and etched. The color stainless steel etching is made by etching various patterns on the surface of the material by chemical method. The 8K mirror panel or drawing plate plate, etching treatment, on the surface of the deep processing, can be partial and local lines, drawing, inlaid with gold and titanium and other kinds of complex process, realize the pattern of light and colorful effect. Etching stainless steel including color stainless steel etching, a variety of patterns, for the selection of color: titanium black (Hei Tai), sky blue, titanium gold, sapphire blue, brown, brown, purple, bronze, green bronze, champagne gold, rose gold, purple, white, green, green, suitable for: star hotel KTV, a large shopping mall, senior entertainment etc.. Can also be customized according to customer drawings and requirements, but the need for template fees.

- Q: Can stainless steel sheets be used for decorative room dividers or partitions?

- Yes, stainless steel sheets can be used for decorative room dividers or partitions. Stainless steel is a versatile material known for its durability, strength, and resistance to corrosion, making it a popular choice for various applications. When used as room dividers or partitions, stainless steel sheets can add a sleek and modern aesthetic to any space. They can be customized with different finishes, such as brushed, mirrored, or patterned, to create a unique and decorative look. Stainless steel dividers or partitions are also easy to clean and maintain, making them a practical choice for high-traffic areas or commercial spaces. Overall, stainless steel sheets offer both functionality and style, making them suitable for use as decorative room dividers or partitions.

- Q: What is the magnetic permeability of stainless steel sheets?

- The magnetic permeability of stainless steel sheets may vary depending on the specific alloy and processing conditions. Generally, stainless steel is known for its low magnetic permeability, which means it is not a good conductor of magnetic fields. However, certain types of stainless steel, like ferritic stainless steel, have a higher magnetic permeability compared to other grades such as austenitic stainless steel. It's worth mentioning that factors like temperature and the presence of external magnetic fields can also impact the magnetic permeability of stainless steel. Therefore, it is advisable to refer to specific technical data or conduct magnetic permeability testing for precise and detailed information about the magnetic properties of stainless steel sheets.

- Q: Can stainless steel sheets be used for food packaging?

- Stainless steel sheets are indeed suitable for food packaging purposes. Their utilization in the food industry is widespread owing to the multitude of benefits they offer. This material is incredibly robust and enduring, providing exceptional safeguarding for food items. Moreover, stainless steel exhibits resistance against corrosion, guaranteeing its safety for direct contact with edibles. Not only that, but stainless steel is also effortless to cleanse and maintain, ensuring that proper hygiene standards are upheld. Additionally, stainless steel sheets can be easily molded and shaped into various packaging designs, allowing for a wide range of versatile packaging solutions. Overall, when it comes to food packaging, stainless steel sheets emerge as a dependable and secure choice.

- Q: What's the drill for stainless steel?

- Stainless steel is characterized by high toughness, easy to stick the knife, so requires higher hardness of the drill bit, surface finish is better, the drill tip angle than the ordinary drill (130--135 degrees). At the same time, cooling should be sufficient

- Q: How do you form stainless steel sheets into different shapes?

- Stainless steel sheets can be formed into different shapes through various processes such as bending, cutting, and welding. Bending can be achieved by using specialized tools like press brakes or rollers to apply force and reshape the sheet. Cutting techniques like shearing or laser cutting can be used to create desired shapes or sizes. Additionally, welding is employed to join different stainless steel sheets together, enabling the formation of complex structures and shapes.

- Q: Can stainless steel sheets be used in chemical processing plants?

- Chemical processing plants can utilize stainless steel sheets due to their high resistance to corrosion, which makes them an ideal material for environments with chemical exposure. Stainless steel is capable of enduring exposure to a wide range of chemicals, including acids, alkalis, and solvents, without deteriorating or reacting with them. Furthermore, stainless steel sheets are easily cleaned and maintained, ensuring that they adhere to the stringent hygiene and safety standards demanded in chemical processing plants. Additionally, stainless steel possesses exceptional strength and durability, making it suitable for various applications within the facility, such as tanks, piping, pressure vessels, and heat exchangers. In conclusion, stainless steel sheets are a dependable and versatile option for implementation in chemical processing plants.

- Q: What are the different types of surface treatments available for stainless steel sheets?

- There are several types of surface treatments available for stainless steel sheets, including mirror finish, brushed finish, satin finish, etched finish, embossed finish, and colored finish. These treatments can enhance the appearance, durability, and corrosion resistance of stainless steel sheets, catering to various aesthetic and functional requirements.

- Q: Are stainless steel sheets suitable for nuclear power plants?

- Yes, stainless steel sheets are suitable for nuclear power plants. Stainless steel is a highly durable material that possesses excellent corrosion resistance, mechanical strength, and heat resistance properties, which are crucial requirements for the harsh and demanding environment of nuclear power plants. Additionally, stainless steel's ability to withstand high temperatures and maintain its structural integrity makes it a reliable choice for various components, such as piping, vessels, and heat exchangers, within nuclear power plants.

- Q: What factors affect the cost of stainless steel sheets?

- There are several factors that can affect the cost of stainless steel sheets. These include the type and grade of stainless steel, the thickness and size of the sheets, the quantity being purchased, market demand and availability, production and labor costs, and any additional processing or finishing requirements.

Send your message to us

Stainless Steel Sheet/Plate 201 with Good Corrosion Resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 8500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords