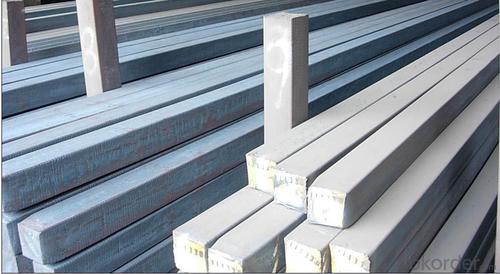

Square Steel Billet Q235 Grade Prime Quality 7#

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Square Steel Billet Q235 Grade Prime Quality 7#

M. S. Billets are used for rolling of TMT Re-Bars of Fe415 and Fe500 Grade and various other structural steel products.

CRS Billets are used for rolling of CRS TMT Re-Bars.

Special Alloy Billets are used for rolling of any special grade TMT Re-Bars like Earthquake resistant TMT Re-Bars and for special grade structural steel products.

Main Feature Square Steel Billet Q235 Grade Prime Quality 7#

Raw elements(C,Fe,Ni,Mn,Cr,Cu.)---Smelted ingots by AOD finery---hot rolled into black suface---pickling in acid liquid---cold drawn----polished by automatically machine--- cutting into pieces---checking quanlity

Applications of Square Steel Billet Q235 Grade Prime Quality 7#

Widely Used in the areas such as Stainless Steel Fasteners, Chains, Kitchen and Sanitary wares, Furniture handles, Handrails, Electroplating and Electrolyzing pendants, Foods, Electron, Petroleum, Construction and Decoration, etc. Products have a high strength after cold-working. Electronic products parts, Medical appliance, Springs, Bus Inside and Outside packaging and building, Street Lamp Posts, etc. Decoration materials and Outdoor Publicity Billboard. Used for the products which have the Anti-Stress Corrosion requirement. Electron Products, Table-wares, Bolts, Nuts, Screen Meshes, Cumbustors and so on.

Specifications of Square Steel Billet Q235 Grade Prime Quality 7#

| Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

| Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

| Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

| Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

| 20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

| 3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

| 5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

FAQ of Square Steel Billet Q235 Grade Prime Quality 7#

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How are steel billets marked for identification and traceability?

- Various methods are utilized to mark steel billets for identification and traceability. One prevalent approach involves the utilization of unique identification numbers or codes. These numbers or codes can be engraved or stamped onto the billet's surface, enabling easy identification. Laser engraving machines or steel stamping tools are frequently employed for this purpose. Aside from identification numbers, other significant details, such as the grade, heat number, and production date, can also be marked on the billet. These details play a crucial role in traceability, allowing for the tracking of the steel's origin and quality. Moreover, some manufacturers may choose to employ additional marking techniques, such as paint or ink marking. This may entail the use of specific colors or symbols to represent different characteristics or attributes of the billet. For example, a particular color might indicate the intended use of the steel, while a symbol may signify the manufacturer's logo or quality certification. Overall, the marking of steel billets for identification and traceability is indispensable in ensuring quality control, verifying compliance with industry standards, and facilitating efficient inventory management throughout the supply chain.

- Q: How do steel billets contribute to the infrastructure development?

- Steel billets are a crucial component in infrastructure development as they serve as the raw material for manufacturing various steel products used in construction. These billets are used to produce reinforcement bars, beams, columns, and other structural elements that provide strength and stability to buildings, bridges, roads, and other infrastructure projects. By providing a strong and durable foundation, steel billets contribute significantly to the overall safety and longevity of infrastructure, promoting sustainable development and economic growth.

- Q: How are steel billets used in the manufacturing of renewable energy equipment?

- The production of renewable energy equipment relies heavily on steel billets. These billets are melted and molded into specific shapes, usually square or rectangular, using a process called casting. Once formed, they undergo further processing and shaping to create the required components. In wind energy, for example, steel billets are used to manufacture the sturdy tower structures that support the wind turbines. These towers must be able to withstand harsh environmental conditions and support the turbine's weight. Steel billets provide the necessary strength and durability to construct these towers, ensuring the longevity and reliability of the turbines. Likewise, in solar energy, steel billets are used in the production of solar panels and mounting structures. Steel frames are necessary to support the photovoltaic cells and shield them from external factors. Additionally, steel billets are used to build the mounting structures that secure the solar panels in place, allowing them to efficiently capture sunlight. Steel billets are also integral to hydroelectric power equipment. They are utilized in the construction of turbines and other components that are submerged in water. These billets require excellent corrosion resistance and high strength to withstand the extreme conditions and forces present in hydroelectric power plants. Moreover, steel billets find applications in the manufacturing of components for other types of renewable energy equipment, such as geothermal power plants and biomass energy systems. They are used in various ways, including as structural supports, heat exchangers, and boilers, where their strength and durability are of utmost importance. In conclusion, steel billets play a crucial role in the production of renewable energy equipment. Their strength, durability, and corrosion resistance make them an ideal material for constructing the essential components of wind turbines, solar panels, hydroelectric power plants, and other renewable energy systems. By providing the necessary structural integrity, steel billets contribute to the efficient and reliable operation of renewable energy equipment, facilitating the transition to a more sustainable and eco-friendly energy future.

- Q: How are steel billets priced in the market?

- Steel billets are typically priced in the market based on various factors such as supply and demand dynamics, production costs, and market conditions. The pricing is influenced by factors such as raw material costs, energy prices, transportation costs, and any applicable taxes or duties. Additionally, market participants consider factors like global economic trends, industry forecasts, and geopolitical events that may impact the overall steel market. Ultimately, steel billet pricing is determined through negotiations between buyers and sellers based on these various factors.

- Q: How are steel billets inspected for defects?

- Steel billets are inspected for defects using various non-destructive testing methods such as visual inspection, ultrasonic testing, magnetic particle inspection, and eddy current testing. These techniques help identify surface cracks, internal flaws, and other defects that may compromise the quality and integrity of the steel billets.

- Q: How are steel billets used in the production of mining machinery?

- Due to their unique properties and versatility, steel billets play a crucial role in the production of mining machinery. These semi-finished metal forms are made from raw iron ore and undergo a series of heating, rolling, and cooling processes to achieve their final shape and properties. In the manufacturing of mining machinery, steel billets are the primary raw material for various important components. Heavy-duty structural parts, such as frames, chassis, and support structures, require high strength and durability to withstand the extreme conditions and heavy loads in mining operations. Steel billets also serve as the foundation for critical functional components like gears, shafts, and axles. These components are vital for the proper functioning and control of mining machinery, as they transmit power and facilitate movement. Steel billets offer excellent machinability, allowing them to be easily shaped into the complex geometries required for these components. Moreover, steel billets are used to produce wear-resistant parts and components that can withstand constant abrasion, impact, and wear. Cutting edges, buckets, and crusher liners are examples of such components. Steel billets are often alloyed with elements like manganese or chromium to enhance their hardness, toughness, and resistance to wear. In the production of mining machinery, steel billets are also utilized for hydraulic components and systems. Hydraulic cylinders, valves, and pumps are essential for the operation and control of mining equipment. Steel billets provide the necessary strength and integrity to withstand high-pressure hydraulic systems, ensuring reliable and efficient performance. In summary, steel billets are indispensable in the production of mining machinery. They are used to manufacture various structural, functional, and wear-resistant components that are vital for the reliable and efficient operation of mining equipment. The unique properties of steel billets, including their strength, durability, and machinability, make them an ideal choice for withstanding the demanding conditions encountered in mining operations.

- Q: How are steel billets used in the production of oil and gas exploration equipment?

- Steel billets are commonly used in the production of oil and gas exploration equipment due to their strength and durability. These billets are shaped and machined into various components such as valves, pumps, drilling tools, and pipelines, which are crucial for the extraction and transportation of oil and gas. The high-quality steel ensures that the equipment can withstand harsh operating conditions, including high temperatures, pressure, and corrosive environments, thereby ensuring the safety and reliability of oil and gas exploration operations.

- Q: What are the potential applications of steel billets in the automotive sector?

- Steel billets have a wide range of potential applications in the automotive sector. One of the key uses of steel billets is in the production of automotive parts and components. These billets can be further processed and shaped into various forms such as rods, bars, and sheets to manufacture critical components like engine parts, chassis, and suspension systems. The strength and durability of steel make it an ideal material for automotive applications. Steel billets can be transformed into high-strength steel alloys, which are known for their excellent mechanical properties, including high tensile strength, hardness, and impact resistance. These properties make steel billets suitable for use in structural components, such as the frame and body of vehicles, providing stability and enhancing passenger safety. Steel billets are also used in the production of engine parts, such as crankshafts, camshafts, and connecting rods. These components require high strength and resistance to wear and fatigue, which steel billets can provide. Additionally, steel billets can be used to manufacture gears, axles, and transmission components, which require excellent mechanical properties to withstand the demanding conditions of the automotive industry. Furthermore, steel billets find application in the manufacturing of suspension systems, including control arms, stabilizer bars, and springs. These components need to withstand heavy loads, vibrations, and impacts while ensuring optimal ride comfort and handling. Steel billets' high strength and toughness make them suitable for these critical suspension components. Moreover, steel billets are also utilized in the production of safety features in automobiles. For instance, they can be used to manufacture reinforced door beams, which enhance the structural integrity of the vehicle and provide protection in the event of a collision. Additionally, steel billets can be employed in the production of seat frames and seatbelt components, ensuring passenger safety and restraint systems. Overall, the potential applications of steel billets in the automotive sector are vast and crucial. Their strength, durability, and excellent mechanical properties make them indispensable for the production of various automotive components, ranging from engine parts to structural elements and safety features.

- Q: How do steel billets contribute to the manufacturing of electrical appliances?

- Steel billets are used in the manufacturing of electrical appliances as they serve as a raw material for various components. These billets are transformed into sheets, wires, or rods which are then used to create the outer casings, frames, or conductive elements of the appliances. The strength and durability of steel make it an ideal choice for ensuring the longevity and safety of electrical appliances.

- Q: What is the role of steel billets in the manufacturing of railway wheels?

- Steel billets play a crucial role in the manufacturing of railway wheels. They serve as the primary raw material used to create these wheels. Railway wheels need to be extremely strong, durable, and able to withstand heavy loads, extreme temperatures, and constant wear and tear. Steel billets are first melted down and then shaped into a cylindrical form, which is similar to the final shape of the railway wheel. These billets are then further processed through a series of manufacturing steps, such as hot rolling, forging, and machining, to transform them into the desired shape and dimensions of the railway wheel. The main advantage of using steel billets is their high strength and toughness. Steel is renowned for its excellent mechanical properties, including high tensile strength and hardness. These characteristics are essential for railway wheels, as they need to bear enormous loads and resist deformation under extreme pressures. Moreover, steel billets provide the necessary metallurgical properties required for railway wheels. They can be alloyed with additional elements such as carbon, manganese, and chromium to enhance their strength, hardness, and resistance to corrosion and fatigue. This ensures that the railway wheels maintain their structural integrity and performance over an extended period of time. In summary, steel billets are the starting point in the manufacturing process of railway wheels. They provide the raw material necessary to create robust, durable, and reliable wheels that can withstand the demanding conditions of railway operations. The use of steel billets ensures that railway wheels meet the stringent requirements for safety, performance, and longevity in the transportation industry.

Send your message to us

Square Steel Billet Q235 Grade Prime Quality 7#

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords