Solar Silicon Wafer Price - 6 inch 3bb Monocrystalline Best Solar Cell 18.0%

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

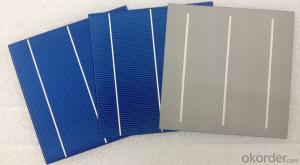

Place of Origin: | China (Mainland) | Brand Name: | xrsolar | Model Number: | ERC-156M-3BB |

Material: | Monocrystalline Silicon | Size: | 6 inch | Number of Cells: | 1 |

Max. Power: | 4.3W | Material:: | monocrystalline Silicon | Size:: | 156mmx156mm or 6 inch |

Max. Power:: | 4.3 watts | efficiency:: | 16%-17.8% | busbar:: | 3 |

Color: | Dark Blue | Voltage:: | 0.508V-0.53V | Thickness:: | 190um±20um |

Packaging & Delivery

Packaging Details: | 100pcs in one box,1000pcs per carton, standard export carton |

Delivery Detail: | 5-7 days after received the payment |

Specifications

3BB Monocrystallin Best Solar Cell Price

1.Size: 6*6 solar cell

2. Efficiency:4.3WMonocrystallin Best Solar Cell Price

6 Inch 3BB Monocrystallin Best Solar Cell Price

Dimension: 156mm x 156mm

Diagonal: 200mm (round chamfers)

Front: Anisotropically texturized surface and dark silicon nitride

anti-reflection coating

1.9mm silver busbars

Back: Full-surface aluminum back-surface field

4.0mm (silver / aluminum) continuous soldering pads

Features

1.High conversion efficiencies resulting in superior power output performance.

2.Outstanding power output even in low light or high temperature conditions

3.Optimized design for ease of soldering and lamination

4.Long-term stability,reliability and performance

5.Low breakage rate

6.Color uniformaity

Packaging & Shipping

1. Item are only shipped after PAYMENT is received.

2. Originally our solar cells are 100 pieces per box, 10 boxes per carton.

2. Please check out your ADDRESS carefully when processing order.

3. Please CONTACT us ASAP if you haven't received the parcel.

Shipping will be made via EMS, DHL, Fedex, UPS , TNT etc

FAQ:

1. Q: Do you have your own factory?

A: Yes, we have. Our factory located in Jiangsu

2. Q: How can I visit your factory?

A: Before you visit,please contact us.We will show you the route or arrange a car to pick you up.

3. Q: Do you provide free sample?

A: Commenly we provide paid sample.

4. Q: Could you print our company LOGO on the nameplate and package?

A: Yes, we accept it.And need an Authorization Letter from you.

- Q: Are solar silicon wafers affected by electromagnetic interference (EMI)?

- Solar silicon wafers are not directly affected by electromagnetic interference (EMI). However, the performance of solar panels, which use these wafers, can be influenced by EMI. EMI can interfere with the proper functioning of the electrical components in a solar system, such as inverters or charge controllers, leading to reduced efficiency or even system failure. Therefore, while silicon wafers themselves are not affected, precautions need to be taken to minimize the impact of EMI on the overall solar power system.

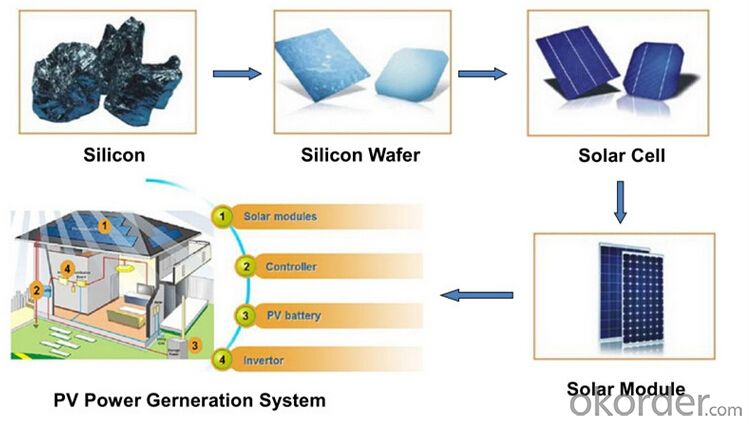

- Q: Can solar silicon wafers be used in solar water heating systems?

- Yes, solar silicon wafers can be used in solar water heating systems. These wafers are commonly used in photovoltaic (PV) solar panels to convert sunlight into electricity. However, they can also be utilized in solar thermal systems, including solar water heating, where the sunlight is directly used to heat water.

- Q: Are solar silicon wafers affected by ultraviolet (UV) radiation?

- Yes, solar silicon wafers are affected by ultraviolet (UV) radiation. UV radiation can cause degradation and damage to the silicon material used in solar cells, reducing their efficiency and overall performance over time. Therefore, it is important to take precautions and use protective coatings or materials to minimize the impact of UV radiation on solar silicon wafers.

- Q: Are there any advancements in solar silicon wafer technology?

- Yes, there have been significant advancements in solar silicon wafer technology. These advancements include the development of thinner wafers, increased efficiency in converting sunlight into electricity, and the use of alternative materials such as multi-crystalline silicon and thin-film solar cells. Additionally, new manufacturing processes and techniques have been introduced to reduce costs and improve the overall performance of solar silicon wafers.

- Q: How are solar silicon wafers protected from electrical faults or short circuits?

- Solar silicon wafers are protected from electrical faults or short circuits through various methods, such as the implementation of anti-reflective coatings, passivation layers, and junction boxes. These protective measures help to prevent direct contact between the conducting materials and the silicon wafer, reducing the likelihood of electrical faults or short circuits. Additionally, quality control measures during the manufacturing process ensure that the wafers are free from any defects or impurities that could potentially lead to electrical issues.

- Q: How much is the thickness of the silicon wafer

- And two knives. We do DIP package, 4 inch wafer to thin to 0.300mm; 6 inch wafer to be reduced to about 0.320mm, error 0.020mm.

- Q: What is the role of a passivation layer in a solar silicon wafer?

- The role of a passivation layer in a solar silicon wafer is to prevent or reduce surface recombination of charge carriers, which improves the efficiency and performance of the solar cell.

- Q: What are the different types of mounting structures used for solar silicon wafers?

- The different types of mounting structures used for solar silicon wafers include fixed tilt, single-axis tracking, and dual-axis tracking systems. Fixed tilt structures hold the solar panels at a fixed angle, while single-axis tracking structures allow the panels to move along one axis to follow the sun's path. Dual-axis tracking structures enable the panels to move along both vertical and horizontal axes, maximizing their exposure to sunlight throughout the day.

- Q: Can solar silicon wafers be used in disaster relief efforts?

- Yes, solar silicon wafers can certainly be used in disaster relief efforts. They can be utilized to quickly set up temporary or portable solar power systems, providing electricity for emergency communication devices, lighting, medical equipment, and other essential needs in disaster-affected areas where traditional power sources may be disrupted or unavailable. The versatility and efficiency of solar silicon wafers make them a valuable resource in helping communities during times of crisis and aiding in the recovery process.

- Q: What is the typical diameter of a solar silicon wafer?

- The typical diameter of a solar silicon wafer is 156 mm (6.14 inches).

Send your message to us

Solar Silicon Wafer Price - 6 inch 3bb Monocrystalline Best Solar Cell 18.0%

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords