Solar Panel Silicon Wafer PV Solar Panel Price / Solar Cell / Solar Module

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

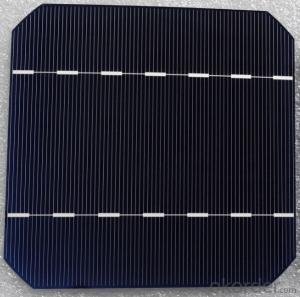

PV Solar Panel Price / Solar Cell / Solar Module

type:156M

appearance:156×1565㎜±0.5mm;diagonal:R=100mm

Main fence wide:1.4-1.5mm back electrode wide:2-2.5mm

Fence line qty:90

Cell thickness:220um±20um

Eff(%) | 18.00- 18.10 | 18.10- 18.20 | 18.20- 18.30 | 18.30- 18.40 | 18.40- 18.50 | 18.50- 18.60 | 18.60- 18.70 | 18.70- 18.80 | 18.80- 18.90 | 18.9- 19.0 | 19.1- 19.1 | 19.1- 19.2 |

Pm(W) | 4.30 | 4.33 | 4.35 | 4.37 | 4.40 | 4.42 | 4.44 | 4.47 | 4.49 | 4.52 | 4.54 | 4.56 |

Isc(A) | 8.71 | 8.73 | 8.76 | 8.77 | 8.78 | 8.82 | 8.83 | 8.85 | 8.86 | 8.88 | 8.9 | 8.93 |

Im(A) | 8.19 | 8.21 | 8.24 | 8.26 | 8.30 | 8.33 | 8.35 | 8.39 | 8.42 | 8.45 | 8.47 | 8.51 |

Voc(V) | 0.630 | 0.631 | 0.632 | 0.633 | 0.634 | 0.634 | 0.635 | 0.636 | 0.637 | 0.637 | 0.638 | 0.64 |

Vm(V) | 0.527 | 0.528 | 0.529 | 0.531 | 0.531 | 0.532 | 0.534 | 0.534 | 0.535 | 0.536 | 0.537 | 0.538 |

FF(%) | 78.6 | 78.7 | 78.8 | 79.0 | 79.2 | 79.3 | 79.5 | 79.6 | 79.8 | 80 | 80 | 80 |

Product Show

Shipping

1. Shipment shall be made only after PAYMENT is received.

2. Please do inform us your DETAILED ADDRESS AND CONTACT INFOMATION before shipment.

3. Shipment shall be made in THREE WORKING DAYS.

- Q: How are solar silicon wafers protected from fire or overheating?

- Solar silicon wafers are protected from fire or overheating through a combination of design features and safety measures. First, the solar panels themselves are typically made with non-flammable materials, such as tempered glass, to minimize the risk of fire. Additionally, the wafers are often encapsulated in a protective layer or surrounded by an insulating material to provide thermal insulation and prevent overheating. Furthermore, solar panels are designed with heat dissipation mechanisms, such as ventilation or cooling systems, to regulate temperatures and prevent excessive heat buildup.

- Q: How do solar silicon wafers perform in dusty and sandy environments?

- Solar silicon wafers can perform well in dusty and sandy environments, although the presence of dust and sand can impact their performance to some extent. The accumulation of dust and sand particles on the surface of solar panels can reduce the amount of sunlight reaching the silicon wafers, resulting in lower energy production. To mitigate this, regular cleaning of the panels is necessary to maintain optimal performance. Additionally, advancements in panel design and coatings have been made to minimize the impact of dust and sand, ensuring better performance in such environments.

- Q: Can solar silicon wafers be used in solar-powered boats?

- Yes, solar silicon wafers can be used in solar-powered boats. These wafers are commonly used in solar panels to convert sunlight into electrical energy. By installing solar panels with silicon wafers on the boat's surface, the sunlight can be harnessed to power the boat's batteries, propelling it forward. This method is an eco-friendly and sustainable way to generate energy for solar-powered boats.

- Q: How do solar silicon wafers contribute to job creation in the solar industry?

- Solar silicon wafers contribute to job creation in the solar industry by serving as a fundamental component in the production of solar cells and modules. As demand for solar energy continues to rise, the manufacturing of silicon wafers expands, leading to the establishment and growth of solar panel manufacturing plants. This expansion creates job opportunities not only in the production and assembly of solar panels but also in related areas such as research and development, quality control, logistics, and sales. Additionally, the deployment of solar panels stimulates the installation and maintenance sector, further contributing to job creation within the solar industry.

- Q: Can solar silicon wafers be used in art installations?

- Yes, solar silicon wafers can be used in art installations. These wafers can be creatively incorporated into various artistic designs to add a unique and sustainable element to the installation.

- Q: How do solar silicon wafers compare to other types of solar cells?

- Solar silicon wafers are the most common type of solar cells used today. They have a higher efficiency and longer lifespan compared to other types of solar cells such as thin-film or organic solar cells. Additionally, silicon wafers have proven to be more reliable and have a better performance in various weather conditions, making them the preferred choice for most solar installations.

- Q: Are there any environmental concerns with the production or disposal of solar silicon wafers?

- Yes, there are some environmental concerns associated with the production and disposal of solar silicon wafers. The production of silicon wafers involves energy-intensive processes and the use of hazardous chemicals, which can contribute to air and water pollution if not managed properly. Additionally, the mining of raw materials for silicon wafers can have negative impacts on ecosystems and communities. Proper disposal and recycling of silicon wafers are also important to prevent potential environmental harm. However, it is worth noting that compared to other energy sources, the environmental impact of solar silicon wafers is relatively lower, and advancements in technology and regulations continue to address these concerns.

- Q: What is a silicon wafer

- Silicon is an important material in the IC fabrication, through photolithography and ion implantation on the silicon wafer and other means, can be made into various semiconductor devices made of silicon chip. With amazing computational capabilities. The development of science and technology promotes the development of semiconductor. Development of automation and computer technology, this makes the silicon chip (integrated circuit) high technology product cost has been reduced to a very low degree. This makes the silicon wafer has been widely used in aerospace, industry, agriculture and national defense, and even crept into every family.

- Q: What are the potential future advancements in solar silicon wafer technology?

- There are several potential future advancements in solar silicon wafer technology. One possibility is the development of thinner wafers, which would reduce material costs and improve the efficiency of solar panels. Another advancement could be the use of higher-quality silicon materials, such as monocrystalline silicon, to enhance the performance of solar cells. Additionally, there is ongoing research in improving the manufacturing processes of silicon wafers, such as the use of advanced deposition techniques or the introduction of new materials, which could further enhance the efficiency and durability of solar panels.

- Q: It is said that monocrystalline silicon, polycrystalline silicon wafer cutting requirements and problems are still quite a lot of

- 1, the impurity line caused by impurities in polycrystalline silicon ingot, slicing process can not completely remove the lead line on a silicon wafer.2, scratch line caused by mortar in large SIC particles or caking mortar. In the process of cutting, SIC particles stuck in between steel wire and silicon can not overflow, cause.Forms: including the whole line and half line marks, concave line, shiny, more narrow than the other.

Send your message to us

Solar Panel Silicon Wafer PV Solar Panel Price / Solar Cell / Solar Module

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords