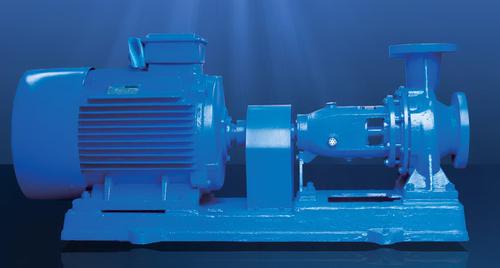

SLNC series horizontal end suction pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Production outline

SLNC series single-stage single-suction cantilever centrifugal pump with reference to foreign famous manufacturer horizontal centrifugal pump, conform to the requirements of the ISO2858, its performance parameters are from the original IS type centrifugal water pump performance parameters optimization, expand and become, its internal structure, the overall appearance IS integrated the original type IS water centrifugal pump and the advantages of existing says Mr Galdi at SLW horizontal pump, cantilever type pump design, make its performance parameters and the internal structure and overall appearance are tend to be more reasonable and reliable.

Manufactured products in strict accordance with the relevant requirements, product quality is stable and reliable performance,for the transport of water and physical and chemical properties similar to water without solid particles in the liquid with.

This series of pump flow range 15-2000m³/h, 10-140m head range, and adjust the rotation speed can be obtained by cutting impeller of nearly 200 types of products, can adapt to all industry demand, according to the rotation speed can be divided into 2950r/min, 1480r/min and 980r/min, press the impeller cutting pattern can be divided into basic, type A,type B, type C and type D.

Product features

1. Compact structure. This series of pump is horizontal structure, beautiful shape, covering an area of less.

2. Smooth running, low noise, high concentricity components.Connected by coupling pump and motor, impeller has good dynamic and static balance, little vibration when running, improving the use environment.

3. No leakage. Shaft sealing adopts corrosion-resistant carbide mechanical seal.

4. Easy maintenance. After this series of horizontal pump is open type structure, do not need to remove the line, can be for maintenance.

- Q: Pump impeller diameter plus assembly what changes? What's the effect on the motor?

- 1., the larger the diameter of the impeller, the greater the head, the greater the flow rate, because the flow of water depends on the speed of rotation of the impeller generated by the centrifugal force and the line speed on the tangent, the greater the diameter, the centrifugal force and the greater the speed of the line. The relationship between the centrifugal pump water delivery and the vacuum degree is that the centrifugal pump is the centrifugal force principle to complete pumping. Without water, the time and space turn will burn out the equipment.2., the head and impeller diameter is related, the larger the impeller, the greater the head, and vice versa. The flow rate has little to do with the impeller diameter. Under the rated conditions, the greater the head, the smaller the flow rate, inversely proportional.

- Q: how much is it to replace timing belt and water pump on a Chrysler voyager 2002?????

- Timing belt can be be anywhere from $200 to $400,but make sure a pro does it beaches if it's put on wrong and off time it can mess up your engine and that would be in the thous..this happened to me.. Water pump idk

- Q: I replaced the water pump on my 1997 acura cl 3.0 v6 vtec. I set the timing how alldata said to. (Lined up marks on timing drive pulley and both cam pulleys) and put it all back together. Now when I start it the motor runs rough for about 45 seconds then it smooths out but won't rev past 3000 rpm. What are some possibilites it could be?

- looks like the force belt broke, or is slipping. The force belt connects the engine to numerous aspects, like your alternator which rates your battery, the water pump, which pushes the coolant around the engine and radiator to relax the engine, and your skill guidance pump, which pressurizes the hydraulic fluid to your skill guidance. do no longer force the motor vehicle back till you fix it. you're able to desire to heavily blow out the motor by using over heating it.

- Q: Can I charge the battery (1.2Vx2) with the suction tube submerged in the water or do I have to remove the suction tube every time I have to charge the battery?

- Since you don't mention the model of the pump, if you can connect the charger with a dry connection, you should not have to remove the pump/tube. If you have to take the battery out, you stand the risk of dropping it in the water putting it back, but obviously (I think) you don't have to remove the pump/tube.

- Q: First the shop put in a heater core, but it was still leaking and overheating. Next they put in a water pump. Went to get it and now it wines really loud and the engine use to purr like a kitten, couldn't even tell it was running, now the engine shakes the whole car and it died one the way home but started again. The shop said the cam positioning needs reset again and on the way back to the shop it died again. So from leaking anti-freeze to now it vibrates, dies and wines really loud ! Any ideas what they did wrong ?

- Matbe they forgot to replace water pump gasket, timing belt not aligned with timing of engine.

- Q: i hear water swirl in my dash board when i take off and when i reverse, i heard its the water pump pushing water through the heater core, but how can i fix it.?

- The issue is not just that the water pump is pumping air through the system, it is that there is an issue with air being in there in the first place. It gets there one of two ways. First, your cooling system is losing water somewhere and air is getting drawn in through the coolant overflow bottle or through a leak in the hoses, the radiator, or the radiator cap. Second it is getting in through a compression leak. Compression leaks are caused by blown head gaskets or cracked or corroded cylinder heads or engine blocks. You need to determine which it is, because you need to address the issues differently. Fill the cooling system with coolant, purge the air out of it, and connect a pressure gauge to the radiator where the cap normally goes. Start the engine. If the gauge fluctuates up and down, you have a compression leak caused by a blown head gasket or crack in the block or head. If the gauge doesn't fluctuate, you have a leak in the cooling system that could be in any one of many places, such as hoses, caps, freeze plugs, the radiator itself, the heater core, or one of many gaskets. If it turns out to be a compression leak, you need to pull off the heads and replace the gaskets, and if there is any corrosion or cracks, you need to either replace or repair the heads. Broken head bolts can also allow compression leaks, so if you do remove the heads, you need to replace the bolts and torque them to the correct specs. If your engine oil looks frothy, like latte, this is another sign that you have a blown head gasket. It means coolant is getting into the engine oil. If it is a leak in the cooling system that is not related to the head gasket, you need to find it and seal it. There is no other way to find out exactly what is allowing air into your cooling system other than these two methods. The sound you hear when water is flowing through your heater core is actually the air gurgling through. No air, no sound.

- Q: where t is in minutes since the pump is started. If the holding tank contains 1000 liters of water when the pump is started, how much water does it hold one hour later?

- Water is pumped out of a holding tank at a rate of 4-4e^(-.14t) liters/minute. Lets call that function w(t). So if we integrate w(t) over a time period that will give us the total water removed over that time period. So lets integrate it from t=0 (time when pump started) to t=60 (one hour later): ∫ w(t) from t=0 to t=60 ∫ w(t)=∫ 4-4e^(-.14t)=4t+(4/.14)e^(-.14t) evaluated from 0 to 60 ∫ w(t)=4(60)+(4/.14)e^(-.14*60)-4(0)-(4/.1... ∫ w(t)=211.435 liters removed If the holding tank began at 1000 liters and 211.435 were removed... Remaining water=1000-211.435 ***Remaining water=788.565 liters***

- Q: We lost power during the hurricane, we have well water. the power went out and we lost water also, what are the procedures to bleed and restart a goulds pumps c48a93a06 water pump?

- 1. you are going to need at least a couple gallons of water in a bucket to re-prime. 2. look for a plug at the top of the pump and remove it. 3. pour water into the plug opening, filling up the pump as much as you can. 4. put plug back in so at least one thread is grabbing. by doing this it will allow air to escape and won't be spraying water everywhere. it is also a good idea to keep your hand on the plug. 5. turn on electricity to pump. 6. when you start to notice pressure re-gaining tighten up the plug so it does not drip. It is also a good idea to have an outside tap on to get air out of the lines. Another thing is, it is a good idea to shut off water to toilets and washing machines before re-starting pump because small debris have a habit of clogging them up. When your pressure is back, drain your toilet and cold water line to your washing machine, flushing all the stuff out until you see nice clear water. Hope I helped and good luck.

- Q: its a honda accord 1991 Lx my car started overheating only when i stop when i go it doesnt overheat what should i check like the water pump

- chances are your radiator cooling fan is not working,could be the cooling fan switch,bad fan motor,or relay

- Q: Is it accurate to say that it should begin at 2, not at 0?

- It freezes at 0 degrees, and the pump runs and gets stuck.

Send your message to us

SLNC series horizontal end suction pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords