Single - Side Climbing Formwork System

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

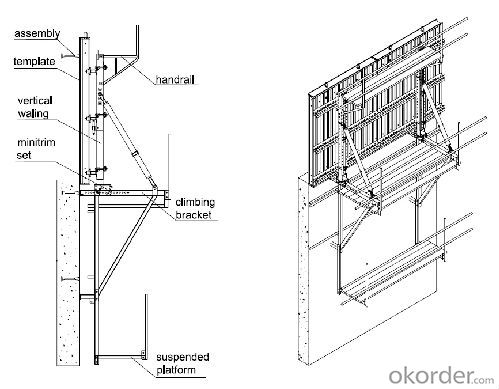

1. Structure of Single - Side Climbing Formwork System

The M30/D20 climbing cones have been designed especially for single-sided concreting using SCB180 in dam construction, and to allow the transfer of high tensile and shear forces into the still fresh, unreinforced concrete. Without wall-through tie-rods, finished concrete is perfect.Typical applications for the SCB 180 system are dams, locks, cooling towers, pier heads, tunnels, and bank vaults.

The formwork is simply tilted backwards when striking takes place. The 1.80 m wide bracket requires only a minimum of space.

It is with the advantages of standard design, excellent applicability and interchangeable.

2. Main Features of Single - Side Climbing Formwork System

A) Stable and cost-effective for high loads.

Generous bracket spacing allow large-area formwork units with optimal utilization of the bearing capacity. This leads to extremely economical solutions.

B) Simple and flexible planning

With SCB180 single-sided climbing formwork, circular structures can also be concreted without undergoing any large planning process. Even use on inclined walls is feasible without any special measures because additional concrete loads or lifting forces can be safely transferred into the structure.

3. Single - Side Climbing Formwork System Images

4. Single - Side Climbing Formwork System Specification

5. FAQ of Single - Side Climbing Formwork System

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

We can provide you the professional design team.

We can provide fashionable and newest styles for you.

We can design the artwork for you.

Please feel free to customize.

2) What promises can be done by us?

If interested in Single - Side Climbing Formwork System, please feel free to write us for any QUOTE.

If printing required, please advise asap because the whole set need much more time to complete.

Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

Response will be carried out in 24hours after receiving any complain or request.

If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

Packing: As Customer's Requirements

Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

Shipping time:Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days. Other mass qty of Single - Side Climbing Formwork System, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: Cantilever support is good or not

- Mainly to see the venue and use. Like singing when playing with the former (to facilitate the performers to play), and recording, broadcast and use the latter (the effect of small effect)

- Q: How to put the microphone line to the cantilever bracket

- Unless you bring their own wheat line, or use a fixed connection.

- Q: Do not know is not the reason for wheat too heavy, cantilever support can not afford the old crooked, I would like to ask how should this

- What is your model of what kind of wheat stent it?

- Q: Taobao sells the capacitor arm of the cantilever bracket has 20, there are 30 +, which is cheap which, cheap that can buy it? The My computer desktop is a glass bracket can clip it? The

- Your desktop is not the glass, and those who buy the shelves of the bar

- Q: How much is the load bearing. Who has a detailed selection of material forms. Month is better.

- Search the shelf height is usually 2.5 meters (such as access to goods by the forklift can be up to 6 meters), cantilever length of 1.5 meters, the load per arm is usually less than 1000KG. Such shelves are used for machinery manufacturing and building materials supermarkets. Plus the shelf, especially for small space, low warehouse, easy management, wide field of vision, compared with ordinary shelf shelves, the utilization rate is higher; according to the carrying capacity can be divided into lightweight, medium, Type three.

- Q: A continuous beam bridge for the 40 +80 +80 +40 hole arrangement, the main beam of concrete strength C50, the use of hanging basket cantilever construction process, the basket structure for the triangular cable-stayed, the length of the closure section of 2m, close Seal of the skeleton made of steel. Question: (1) What are the casting processes? Should be divided into several T structure for construction? (2) the bridge with the first side of the cross-cross after the closure of the construction measures, please meet the closure of the construction should meet the requirements? (3) how to complete the system conversion?

- Chisel addition to the temporary consolidation system is converted from T-structure to continuous beam in the form of the maximum negative moment

- Q: Cantilever pneumatic tapping machine bracket can be flexible to move, cantilever radius can reach up to 2 meters, there are 1.1 meters 1.8 meters Oh, because it is a stent, and some people will worry about attack out of the teeth is not straight! Attack the teeth straight, this is not straight according to the hole and the machine is related to the vertical, so the machine must be a good degree of vertical, okay Oh!

- Since it is also equipped with copper sets, it is recommended to re-repair the aperture, the oval 0.9mm really a little too large, if not repair can be processed into the copper sleeve than the upper limit of small size 0.05mm, sets of holes and then crashed into the workpiece , In the finishing, to prevent the copper sleeve also appears oval phenomenon

- Q: Hurry, Shenzhen shelf factory have what shelf?

- Do you want to store shelves or supermarket shelves? Storage shelves, then there are heavy, medium, attic, etc. to give you a choice

- Q: How to install the cantilever bracket

- Hanging small, then the first construction of hanging scaffolding as a construction platform, and then install.

- Q: What are the shelf systems in warehouses?

- This is based on the landlord of the goods of the big filial species to choose. The In Baidu pictures, enter the shelves, the landlord will see all types of shelves, there are hollow, solid, double shelf, a single shelf. and many more.

Send your message to us

Single - Side Climbing Formwork System

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords