Self Adhesive TPO Membrane Single-ply Roofing System

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- 400000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Self Adhesive TPO Membrane

Product Profle of Self Adhesive TPO Membrane

TPO membrane is a flexible Thermoplastic Polyolefin (FPO) roofing membrane made from the incorporation of a ethylene propylene rubber into a polypropylene matrix. The membrane is specifically formulated for long-term weather resistance without plasticizers.

We produce 4 types of TPO membrane to satisfy all the needs of different applications.

1.Polyester Fleece Backing Thermoplastic Polyolefin Waterproof Membrane

2.Polyester Mesh Reinforced Thermoplastic Polyolefin Waterproof Membrane

3. Homogeneous Thermoplastic Polyolefin Waterproof Membrane

4. Self Adhesive TPO Membrane

Self Adhesive TPO membrane is TPO with self adhesive function. It's easy for installation, saving time and cost, especially labour cost.

Advantages of Self Adhesive TPO Membrane

-Self adhesive TPO membrane is easy for installation, saving time and cost, especially labour cost.

-TPO membrane can be overlapped and hot-air welded, offers exceptionally strong seam.

-Long-term weatherability, excellent durability, the service life of TPO is more than 50 years.

-High solar reflective, energy saving, environmental friendly.

-Excellent durability and root resistance, can be used as root barrier for green roof.

-Excellent the same low temperature resistance as rubber materials which can keep flexible at -40℃.

-Excellent chemical resistance to acids, alkali and salts.

-Available in more than 9 colors.

Applications of Self Adhesive TPO Membrane

-Various roofing waterproof projects, such as industrial and civil buildings, public constructions

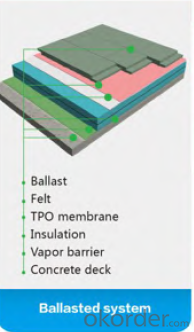

- Full adhered system for concrete substrate or mechanically attached systems or ballasted system.

Propoties of Self Adhesive TPO Membrane

Item | Requirement | Test Method | ||

Thickness, min, mm | Sheet-overall | ≥1.0 | ASTM D6878 | |

Coating over fabric or scrim, weathering side only | ≥0.305 | ASTM D751 | ||

Breaking strength, min, N | ≥976 | ASTM D751 | ||

Elongation at reinforcement break, min, % | ≥15 | ASTM D751 | ||

Tensile strength,min, N | ≥245 | ASTM D751 | ||

Brittleness point, max, °C | ≤-40 | ASTM D2137 | ||

Ozone resistance | no cracks | ASTM D1149 | ||

Properties after heat aging | Breaking strength, % min | ≥90 | ASTM D573 | |

Elongation at reinforcement break, % min | ≥90 | ASTM D573 | ||

Tearing strength, % min | ≥60 | ASTM D573 | ||

Weight change (mass), max % | ≤±1 | ASTM D573 | ||

Linear dimensional change, max, % | ≤±1 | ASTM D1204 | ||

Water absorption, max, mass % | ≤±3.0 | ASTM D471 | ||

Factory seam strength, min, N | ≥290 | ASTM D751 | ||

Weather resistance | Visual inspection | - | ||

Packaging of Self Adhesive TPO Membrane

Thickness | Roll Size | Rolls / Wooden Crate | Wooden Crate / 20’ Container |

1.2 mm | 15 m2 | 25 | 20~25 |

20 m2 | 25 | ||

30 m2 | 25 | ||

1.5 mm | 15 m2 | 25 | |

20 m2 | 25 | ||

30 m2 | 20 |

Above quantities are indicative only. We can produce it according to your demands.

Storage of Self Adhesive TPO Membrane

TPO material should be stored in well-ventilated place and avoid being exposed to the sun or rain. The temperature in stored places can not be higher than 45° C. It only can be put horizontally in five-level. It has to be avoided acid, alkali, oil and organic solvents. The shelf life is 1 year.

Transportation of Self Adhesive TPO Membrane

TPO material should avoid inclination or lateral drift during transportation. When necessary, covering with felted fabric.

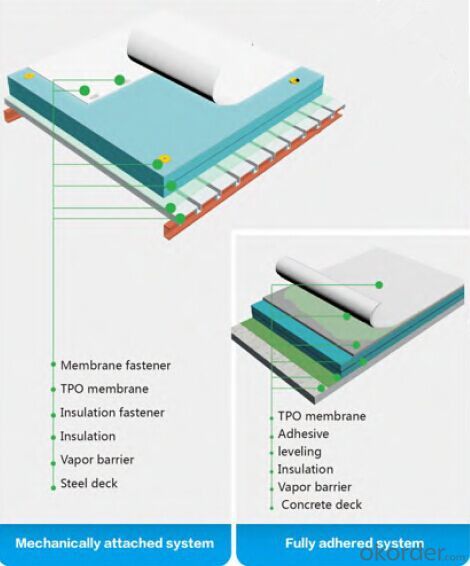

Application System of Self Adhesive TPO Membrane

We not only provides TPO waterproofing membrane, but also dedicates to integrated roofing systems. TPO single ply roofing waterproof system includes mechanically attached roofing system, fully adhered roofing system and ballasted roofing system.

Application Methods of Self Adhesive TPO Membrane

● For Mechanically Attached Roofing System

Before application, spread TPO membranes on substrate in advance. Install TPO membranes perpendicular to steel deck ribs on the substrate without distortions according to the flange. The overlapping width is 120 mm. The minimum overlapping distance of membrane short side direction is 50 mm. Fasteners are installed according to designed position. Hot-air welding is adopted for laps with 40 mm welding width.

● For Fully Adhered Roofing System

Before application, spread TPO membranes on substrate in advance. Install TPO membranes on the substrate without distortions according to the flange. The overlapping width should be more than 50 mm. Hot-air welding is adopted for laps with 40 mm welding width. Professional adhesives need to be used on both underside and substrate surfaces to adhere and maintain.

● For Ballasted Roofing System

Before application, spread TPO membranes on substrate in advance. Install TPO membranes on the substrate without distortions according to the flange. The overlapping width should be more than 50 mm. Hot-air welding is adopted for laps with 40 mm welding width.

Attentions

● TPO membranes reflect heat and light, wearing protective clothing (long-sleeved shirt, long-barreled trousers), and wearing a filter to protect the skin and eyes from UV-induced damage.

● Security measures for roof perimeter are necessary when application. Sheet surface is slippery when wet, taking care to avoid slide.

● Sealants and adhesives are flammable containing solvents. They will be dangerous when exposure to heat, even have the possibility to catch fire and explode.

● Sealants, adhesives, cleaners should be avoided contacting with skin and eyes.

● No smoking during application.

FAQ

1. What’s your production ability of TPO membrane per year?

We own the largest EPDM production line in China. Our product ability of TPO membrane reaches 500million square meters.

2. How's your products quality?

Our TPO is with the top quality at home and abroad. Our quality is much higher than Chinese standard, they can satisfy the certification of CE, GOST-R, FM.

3. What's the service life of your TPO membrane?

The service life of our TPO membrane is more than 50 years.

4.What's your MOQ?

Our MOQ is 4000M2.

5. Can you provide free of charge samples for testing quality?

Yes, we’re very glad to send you free of charge samples for checking. You just need to pay for the freight cost.

6. How do you protect TPO membrane in transportation?

We package TPO rolls by PE bag, then 20~25 rolls will be packed into one big wooden crate.

7. Can you customize TPO membrane?

Yes, we’re very glad to customize TPO membrane according to your requirement. We can do more than 9 colors, and customize the thickness and width according to your requirement.

Photos

- Q: How does a waterproofing membrane handle temperature fluctuations?

- A waterproofing membrane is designed to handle temperature fluctuations by being flexible and resistant to thermal expansion and contraction. Temperature fluctuations can cause materials to expand and contract, which can lead to cracks, leaks, and other forms of damage. However, a waterproofing membrane is typically made from a durable and flexible material, such as PVC or EPDM, that can withstand these changes in temperature without compromising its effectiveness. When exposed to high temperatures, the membrane will expand slightly to accommodate the increased thermal energy. Conversely, when temperatures drop, the membrane will contract to maintain its integrity. This flexibility allows the membrane to adapt to the changing conditions without cracking or becoming brittle. In addition to being flexible, a waterproofing membrane is also designed to resist UV radiation from the sun. UV radiation can cause materials to deteriorate over time, leading to decreased performance and potential leaks. By incorporating UV stabilizers into the membrane's composition, it can withstand prolonged exposure to sunlight and maintain its durability even in harsh weather conditions. Furthermore, some waterproofing membranes have built-in insulation properties that help to regulate temperature fluctuations. These membranes can provide additional thermal resistance, reducing heat loss in cold weather and minimizing heat gain in hot weather. This insulation layer helps to stabilize the temperature of the underlying structure, preventing damage caused by extreme temperature changes. Overall, a waterproofing membrane is engineered to handle temperature fluctuations by being flexible, resistant to thermal expansion and contraction, and capable of withstanding UV radiation. These properties ensure that the membrane remains intact and effective in protecting the underlying structure from water damage, regardless of the surrounding temperature conditions.

- Q: Can a waterproofing membrane be used for tunnels or subway systems?

- Yes, a waterproofing membrane can be used for tunnels or subway systems. It is a common practice to use waterproofing membranes in underground structures to prevent water infiltration and protect the structural integrity of the tunnels or subway systems. These membranes are designed to provide a barrier against water, ensuring the safety and longevity of the underground infrastructure.

- Q: Can a waterproofing membrane be installed on a sloping surface?

- Indeed, on a sloping surface, one can install a waterproofing membrane. In fact, it is frequently essential to do so in order to guarantee adequate drainage and prevent the accumulation of water. The process of installation may differ depending on the specific type of waterproofing membrane employed; however, it generally entails preparing the surface, administering a primer or adhesive, and meticulously positioning and securing the membrane. It is crucial to verify that the membrane is correctly installed and sealed to effectively safeguard against water infiltration, particularly on a sloping surface where water can effortlessly flow and gather.

- Q: Can a waterproofing membrane be used for plant rooms and mechanical equipment areas?

- Yes, a waterproofing membrane can be used for plant rooms and mechanical equipment areas. Plant rooms and mechanical equipment areas often require waterproofing to protect the equipment and surrounding structures from water damage. A waterproofing membrane is a commonly used solution for this purpose. It creates a barrier that prevents water from penetrating into the plant rooms and mechanical equipment areas, ensuring that the equipment remains dry and protected. The waterproofing membrane also helps to prevent moisture-related issues such as mold and mildew growth, which can be detrimental to the operation of the equipment and the overall functionality of the plant room. Overall, using a waterproofing membrane in plant rooms and mechanical equipment areas is a reliable and effective way to ensure the longevity and performance of the equipment and structures.

- Q: Can a waterproofing membrane be used on stadium seating areas?

- Indeed, stadium seating areas can benefit from the application of a waterproofing membrane. Typically utilized to shield structures from water-related harm, such as roofs, basements, and decks, waterproofing membranes prove invaluable. Stadium seating areas, being frequently exposed to the elements like rain and snow, are susceptible to water damage if not adequately safeguarded. The implementation of a waterproofing membrane effectively thwarts water infiltration, thereby averting potential predicaments including mold proliferation, material deterioration, and structural impairment. It is crucial to select a top-notch waterproofing membrane specifically formulated for outdoor usage, capable of enduring heavy foot traffic, thus guaranteeing enduring protection for the stadium seating areas.

- Q: Can a waterproofing membrane be used on tunnels with water drainage systems?

- Yes, a waterproofing membrane can be used on tunnels with water drainage systems. The membrane acts as a barrier, preventing water from penetrating the tunnel structure and directing it towards the drainage system for proper disposal. This helps to ensure the integrity and longevity of the tunnel while effectively managing water flow.

- Q: Can a waterproofing membrane be used for swimming pool decks or patios?

- Yes, a waterproofing membrane can be used for swimming pool decks or patios.

- Q: Is a waterproofing membrane suitable for below-grade applications?

- A waterproofing membrane is a suitable choice for below-grade applications, where the areas are situated beneath ground level, like basements or foundations. These regions are susceptible to water infiltration and moisture problems, which can result in harm and structural issues. The purpose of a waterproofing membrane is to prevent water from entering and act as a barrier against moisture. It can be applied either on the exterior or interior surface of the below-grade structure, creating a continuous and long-lasting seal. This membrane effectively prevents water from seeping into the below-grade area, ensuring a dry and stable environment. It is crucial to utilize a waterproofing membrane in below-grade applications to safeguard the structure against water damage, the growth of mold, and other associated concerns.

- Q: Can a waterproofing membrane be used on insulation surfaces?

- Yes, a waterproofing membrane can be used on insulation surfaces. It provides an additional layer of protection to prevent moisture infiltration and damage to the insulation material.

- Q: Can a waterproofing membrane be used on gypsum block surfaces?

- Yes, a waterproofing membrane can be used on gypsum block surfaces. Gypsum blocks are porous and can be prone to moisture infiltration, so applying a waterproofing membrane can help prevent water damage and moisture-related issues.

Send your message to us

Self Adhesive TPO Membrane Single-ply Roofing System

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- 400000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords