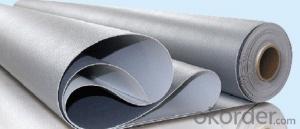

Thermoplastic Polyolefin (TPO)Roofing Membrane for Roofing Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product features of TPO Waterproof Membrane for Roofing Market:

1.high reflectivity,anti-ultraviolet radiation,do not need to be protection,energy saving and environmental protection.

2.long-term weathering resistance,resistance to ultravoilet radiation and heat aging,density is small.

3..high elasticity,high strength,high elongation,good suppleness.

4.effectively resist harmful chemicals,industrial pollutants erosion,wear resistance,resistance to puncture.

5.with automatic quench.

Features of Thermoplastic Polyolefin (TPO)Roofing Membrane for Roofing Industry:

- Easy installation with good system integrity, need few accessories

- High tensile and tear strength, puncture resistance

- No plasticizer, heat aging and UV resistance, durable

- Hot-air welding, rapid welding speed, high peel strength (two times of PVC)

-No chlorine, 100% recyclable, environment friendly

- Durable hot-air welding performance and convenient maintainance

- Smooth surface, unfading and stain resistance

Applications of Thermoplastic Polyolefin (TPO)Roofing Membrane for Roofing Industry:

- Roof construction & steel structure of both industrial and civil engineering

- Underground engineering, such as subways, tunnels, air Raid shelter, etc.

- Sewage treatment, dam, reservoir and basement, grain storehouse, etc."

Technical Parameters of Thermoplastic Polyolefin (TPO)Roofing Membrane for Roofing Industry:

No. | Item | Index | |||

1 | mm≥ thickness of resin layer above inermediate tire mm ≥ | - | - | 0.4 | |

2 | tensile property | N/cm ≥ maximum tensile force N/cm ≥ | - | 200 | 250 |

MPa ≥ tensile Strength MPa ≥ | 12.0 | - | - | ||

≥ elongation at maximun tensile force% ≥ | - | - | 15 | ||

% ≥ elongation at fracture % ≥ | 500 | 250 | - | ||

3 | size change rate under heat treatment %≤ | 2.0 | 1.0 | 0.5 | |

4 | flexibility at low temperature | no crack at -40°c | |||

5 | unpermeability | 0.3Mpa,2h waterproof | |||

FRQ:

What is your main market?

Our Tpo Roofing Membrane with Superior Raw Material for Roofing Market sells very well in USA, United Kingdom, Austrilia, Canada, Japan, Pakistan, etc.

What is your advantage for Tpo Roofing Membrane?

With the most advanced production line, our good quality is based on superior material imported from America. We have different color available and could produce any color you want.

- Q: What are the requirements for the storage of waterproofing membranes?

- Stand up to release the time can not put too long or how you put the deformation will be ..... so we generally stand

- Q: Can a waterproofing membrane be used on bridges?

- Yes, a waterproofing membrane can be used on bridges. It is a common practice to use waterproofing membranes on bridge decks to protect them from water infiltration, which can cause damage and deterioration over time. The membrane acts as a barrier, preventing water from penetrating the bridge deck and protecting the underlying structure.

- Q: Can a waterproofing membrane be used on precast brass surfaces?

- No, a waterproofing membrane cannot be used on precast brass surfaces. Brass is a non-porous material, therefore it does not require waterproofing.

- Q: Can a waterproofing membrane be used for a rooftop garden protection?

- Yes, a waterproofing membrane can be used for rooftop garden protection. Waterproofing membranes are designed to create a barrier against water penetration, preventing leaks and protecting the underlying structure. By installing a waterproofing membrane on the rooftop, it helps to protect the garden and prevent water damage to the building.

- Q: Can a waterproofing membrane be used on tunnels with seismic protection systems?

- Tunnels equipped with seismic protection systems can indeed benefit from the use of a waterproofing membrane. It is strongly advised to employ such a membrane in order to avoid water infiltration and subsequent harm to the tunnel's integrity. Seismic protection systems are engineered to absorb and dissipate the seismic energy released during an earthquake, guaranteeing the tunnel's safety and stability. However, these systems do not provide any defense against water ingress. By incorporating a waterproofing membrane, the tunnel can be shielded from potential water leaks and seepage, which can result in reinforcement corrosion, concrete deterioration, and overall structural impairment. It is crucial to opt for a waterproofing membrane specifically designed for tunnel use, taking into account qualities such as flexibility, durability, and resistance to seismic-induced movement. Moreover, precise detailing and installation techniques must be employed to ensure a seamless and efficient waterproofing system that complements the tunnel's seismic protection measures.

- Q: Can a waterproofing membrane be used on interior walls?

- Yes, a waterproofing membrane can be used on interior walls to prevent water infiltration and moisture damage.

- Q: Basement SBS Waterproof Coil Division I and II type What is the difference? How is the site identified?

- Type I low temperature flexibility is -20 degrees, pulling force of 500N / 5cm, elongation of 30%. Type II low temperature is -25 degrees, tension of 800N / 5cm, elongation of 40%. The appearance of the general can not distinguish, you can take the sample to the laboratory to be a tensile test on it.

- Q: Is the foundation pit waterproofing and the foundation pouring on the working face?

- 3, you say waterproof and pouring concrete conflict? Do not conflict

- Q: Can a waterproofing membrane be used for foundation walls and footings?

- Yes, a waterproofing membrane can be used for foundation walls and footings. A waterproofing membrane is a thin layer of material, typically made of rubberized asphalt or polymer-modified bitumen, that is applied to the exterior surface of foundation walls and footings to prevent water penetration. It acts as a barrier, preventing water from seeping into the foundation and causing moisture-related issues such as dampness, mold, and structural damage. The waterproofing membrane is typically applied to the foundation walls and footings during the construction phase, either before or after the concrete is poured. It is important to ensure that the membrane is properly installed and sealed to provide effective waterproofing. The membrane is also commonly combined with other waterproofing techniques such as drainage systems and sump pumps to provide comprehensive protection against water intrusion. Using a waterproofing membrane for foundation walls and footings is a common practice in construction, especially in areas with high water tables or heavy rainfall. It is an effective and reliable method to prevent water damage and increase the longevity of the foundation. Properly waterproofing the foundation walls and footings is essential for maintaining a dry and structurally sound building.

- Q: Are waterproofing membranes resistant to ponding water?

- Yes, waterproofing membranes are generally resistant to ponding water. Waterproofing membranes are designed to create a barrier that prevents water from seeping through and causing damage to the underlying structure. This includes standing or ponding water that may accumulate on the surface. However, it is important to note that the effectiveness of waterproofing membranes can vary depending on the specific product and installation technique used. It is recommended to consult with a professional to ensure the correct membrane is selected and installed properly to provide the desired level of resistance to ponding water.

Send your message to us

Thermoplastic Polyolefin (TPO)Roofing Membrane for Roofing Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords