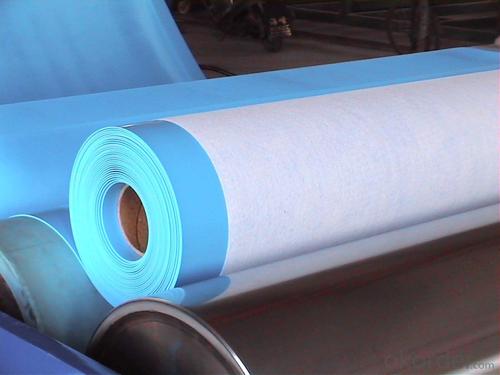

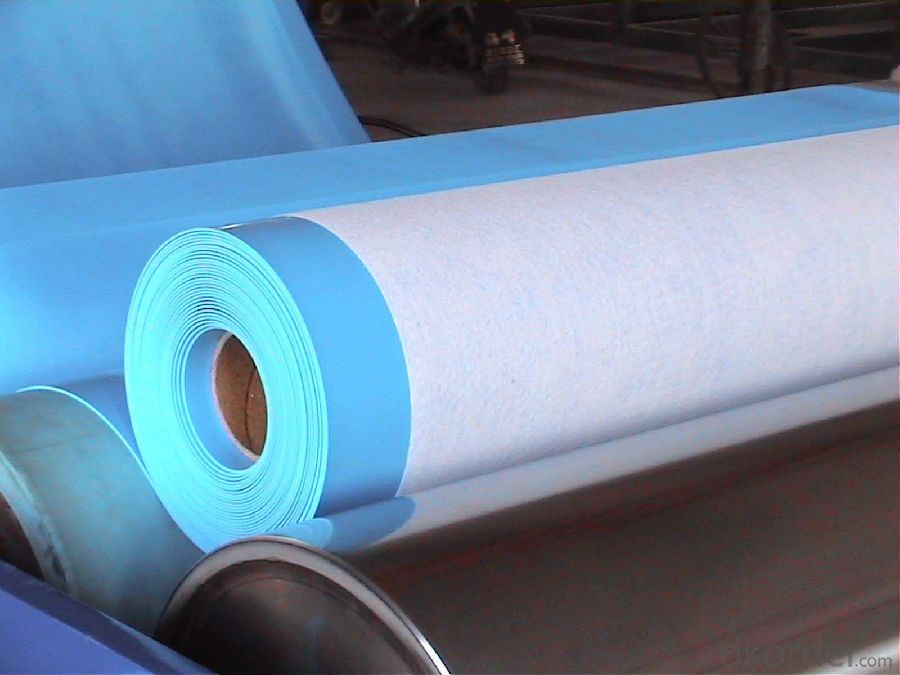

TPO Waterproof Membrane for Roofing Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of TPO Waterproof Membrane for Roofing Construction:

Thermoplastic polyolefin (TPO) membrane is based on polypropylene and EP (ethylene-propylene) rubber polymerized together by using state-of-the-art polymer manufacturing technology. This technology enables TPO membranes flexible at low temperatures without the use of polymeric or liquid plasticizers.TPO membranes fall into two main types: Homogeneous TPO & Reinforced TPO. Reinforced TPO has a polyester mesh layer in the middle, which provides reinforced membranes with high breaking and tearing strength and puncture resistance."

Main Features of TPO Waterproof Membrane for Roofing Construction:

- Easy installation with good system integrity, need few accessories

- High tensile and tear strength, puncture resistance

- No plasticizer, heat aging and UV resistance, durable

- Hot-air welding, rapid welding speed, high peel strength (two times of PVC)

-No chlorine, 100% recyclable, environment friendly

- Durable hot-air welding performance and convenient maintainance

- Smooth surface, unfading and stain resistance

Specifications of TPO Waterproof Membrane for Roofing Construction:

| Type | Thickness (mm) | Weight (kg/sqm) | Roll Size (m) | Colors | 20ft Container |

| Homogeneous TPO waterproof membrane | 1.0 mm | 1.63kg/sqm | 2.05m x 20m | White/ Grey | 14000 sqm |

| 1.2 mm | 1.83kg/sqm | 2.05m x 20m | White/ Grey | 12000 sqm | |

| 1.5 mm | 2.24kg/sqm | 2.05m x 20m | White/ Grey | 10000 sqm | |

| 2.0 mm | 2.30kg/sqm | 2.05m x 20m | White/ Grey | 9000 sqm | |

| Reinforced TPO waterproof membrane | 1.2 mm | 1.83kg/sqm | 2.05m x 20m | White/ Grey | 12000 sqm |

| 1.5 mm | 2.24kg/sqm | 2.05m x 20m | White/ Grey | 10000 sqm | |

| 2.0 mm | 2.30kg/sqm | 2.05m x 20m | White/ Grey | 9000 sqm |

Applications of TPO Waterproof Membrane for Roofing Construction:

- Roof construction & steel structure of both industrial and civil engineering

- Underground engineering, such as subways, tunnels, air Raid shelter, etc.

- Sewage treatment, dam, reservoir and basement, grain storehouse, etc.

FAQ:

1. What are we supplying?

We are specialized in producing TOP membrane, Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used for a swimming pool deck coating?

- Yes, a waterproofing membrane can be used for a swimming pool deck coating. A waterproofing membrane is designed to prevent water penetration and protect the underlying surfaces. When applied correctly, a waterproofing membrane can create an effective barrier against water and moisture, making it an ideal choice for a swimming pool deck coating. It can help prevent water damage, such as cracking, spalling, or deterioration, and also provide a non-slip surface for added safety. Additionally, a waterproofing membrane can help extend the lifespan of the pool deck by protecting it from water-related issues. Overall, using a waterproofing membrane for a swimming pool deck coating is a practical and beneficial choice.

- Q: Are waterproofing membranes suitable for residential basements?

- Yes, waterproofing membranes are suitable for residential basements. These membranes are designed to prevent water infiltration and protect the basement against moisture damage. They create a barrier that keeps water out, helping to keep the basement dry and free from water-related issues like mold and water damage.

- Q: Can a waterproofing membrane be used on precast chrome surfaces?

- Yes, a waterproofing membrane can be used on precast chrome surfaces. Waterproofing membranes are often used to protect surfaces from water damage and prevent moisture from seeping into the structure. Precast chrome surfaces can also benefit from the application of a waterproofing membrane to ensure their longevity and durability. The membrane will create a barrier between the surface and any potential water intrusion, thereby protecting the precast chrome and maintaining its appearance and functionality. It is important to choose a waterproofing membrane that is compatible with chrome surfaces and follow the manufacturer's instructions for proper application.

- Q: Are waterproofing membranes resistant to punctures?

- Yes, waterproofing membranes are designed to be resistant to punctures. These membranes are typically made from durable materials such as polyvinyl chloride (PVC), thermoplastic olefin (TPO), or ethylene propylene diene terpolymer (EPDM), which are known for their strength and ability to withstand external pressures. Additionally, waterproofing membranes are often reinforced with polyester or fiberglass to further enhance their puncture resistance. However, it is important to note that while waterproofing membranes are designed to be highly resistant to punctures, they may still be susceptible to damage if subjected to sharp objects or excessive force. Therefore, it is essential to handle and install these membranes with care to maintain their integrity and effectiveness.

- Q: Are waterproofing membranes resistant to diesel fuel?

- Typically, diesel fuel is not resisted by waterproofing membranes. Being a petroleum-based substance, diesel fuel can harm various types of waterproofing materials. The membrane's integrity can be degraded, reducing its ability to prevent water from penetrating. Consequently, it is crucial to avoid exposing waterproofing membranes to diesel fuel since it can compromise their effectiveness and durability. If there is a chance of diesel fuel coming into contact with the membrane, it is advisable to employ extra protective measures like chemical-resistant barriers or a secondary containment system to avert any potential harm to the waterproofing membrane.

- Q: Can a waterproofing membrane be used on galvanized surfaces?

- Yes, a waterproofing membrane can be used on galvanized surfaces. The membrane provides an additional layer of protection against water penetration, which is especially important for galvanized surfaces that may be prone to rusting or corrosion.

- Q: Can a waterproofing membrane be used in basements and foundations?

- Yes, a waterproofing membrane can be used in basements and foundations. In fact, it is often recommended to install a waterproofing membrane in these areas to protect against water penetration and moisture issues. The membrane is typically applied to the exterior side of the foundation walls and basement floors, forming a barrier that prevents water from seeping through the concrete. This helps to keep the basement and foundation dry, reducing the risk of water damage, mold growth, and structural issues. Waterproofing membranes are available in various types, such as bituminous, rubberized asphalt, and liquid-applied membranes, allowing for flexibility in choosing the most suitable option based on the specific requirements of the project. Overall, installing a waterproofing membrane is an effective way to enhance the longevity and durability of basements and foundations.

- Q: Can a waterproofing membrane be applied in cold weather or during winter months?

- Yes, a waterproofing membrane can be applied in cold weather or during winter months. However, it is important to follow the manufacturer's guidelines and use products specifically designed for cold weather applications. Cold weather may affect the curing time of the membrane, so it is recommended to take necessary precautions and allow sufficient time for proper curing to ensure the effectiveness of the waterproofing.

- Q: Can a waterproofing membrane be used in swimming pools?

- Yes, a waterproofing membrane can be used in swimming pools. In fact, it is a common practice to use waterproofing membranes in the construction or renovation of swimming pools to prevent water leakage. These membranes are specifically designed to create a barrier against water penetration, ensuring that the pool remains watertight and free from leaks. The membranes are typically made from durable materials such as PVC, EPDM, or polyurethane, which are resistant to water, chemicals, and UV rays. Additionally, the membranes are flexible and can easily adapt to the shape and contours of the pool, providing a seamless and long-lasting waterproofing solution.

- Q: What is the PEDM waterproofing membrane material?

- Process: clean up the grassroots → brushing the primary treatment agent → additional layer of treatment → film paste surface coating → base surface coating → coil bonding, exhaust, compaction → coil joint bonding, compaction → roll Material end of the head and edge processing → do protection.

Send your message to us

TPO Waterproof Membrane for Roofing Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords