Silicone Roof Coating

Silicone Roof Coating Related Searches

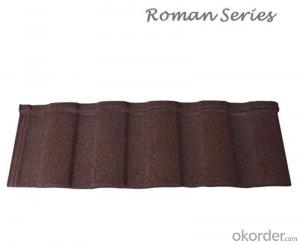

Solid Polycarbonate Roofing Corrigated Plastic Roofing Synthetic Felt Roofing Silver Roof Paint Corrugated Roof Sealant Synthetic Slate Roofing Roof Sealer Spray Foam Roofing Asphaltic Roofing Roof Polycarbonate Roof Cement Roofing Sealer Roof Insulation Materials Sip Roof Resin Roof Spray On Roofing Clear Corrugated Plastic Roofing Wavy Plastic Roofing Iso Roofing Heat Reflective Material For Roof Copper Roofing Material Industrial Roofing Roof Insulation Materials Comparison Corrugated Polycarbonate Roofing Stone Coated Steel Roof Roof Foam Board Insulation Cast Iron Roof Rubber Roofing Underlayment Attaching Solar Panels To Roof Iko RoofingSilicone Roof Coating Supplier & Manufacturer from China

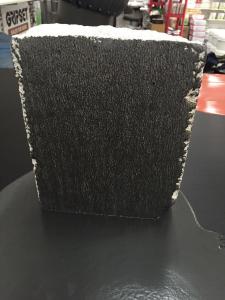

Silicone Roof Coating is a high-performance, water-based product designed to protect and extend the life of various roofing materials. It is formulated with advanced silicone technology to provide excellent resistance against UV rays, weathering, and temperature fluctuations, ensuring the longevity of the roof. This coating is ideal for both residential and commercial applications, offering a durable and cost-effective solution for maintaining the integrity of the roof.The application of Silicone Roof Coating is versatile, as it can be used on a variety of roofing surfaces such as metal, asphalt, and concrete. It is particularly useful in scenarios where traditional roofing materials are prone to damage or wear, providing a protective barrier that can prevent leaks and other issues. This product is also environmentally friendly, as it does not contain harmful chemicals or volatile organic compounds (VOCs), making it a safe choice for both the environment and building occupants.

Okorder.com is a leading wholesale supplier of Silicone Roof Coating, boasting a large inventory to meet the demands of various projects. As a reliable source for this product, Okorder.com ensures that customers have access to high-quality Silicone Roof Coating at competitive prices. With their extensive stock and commitment to customer satisfaction, Okorder.com is the go-to destination for those seeking to purchase Silicone Roof Coating for their roofing needs.

Hot Products