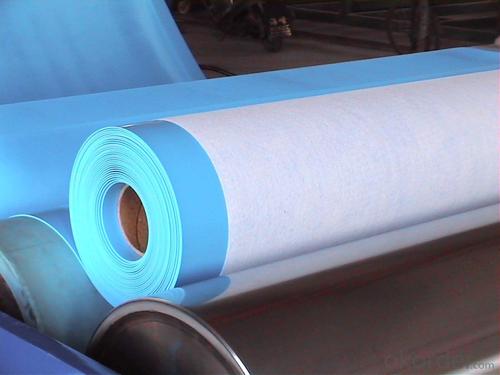

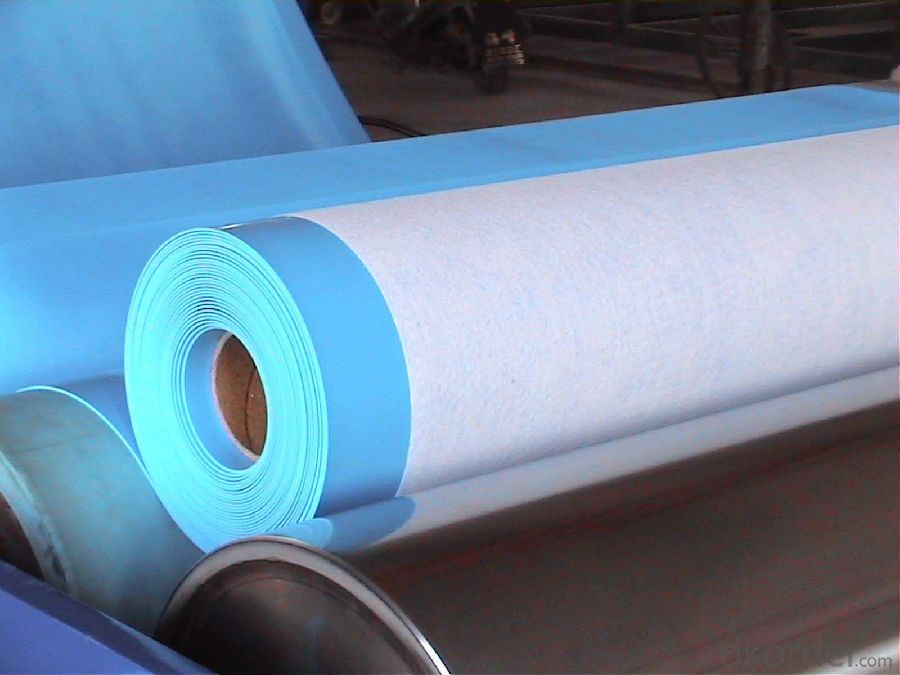

TPO Waterproof Membrane for Rooftop and Room

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of TPO Waterproof Membrane:

Thermoplastic polyolefin (TPO) membrane is based on polypropylene and EP (ethylene-propylene) rubber polymerized together by using state-of-the-art polymer manufacturing technology. This technology enables TPO membranes flexible at low temperatures without the use of polymeric or liquid plasticizers.TPO membranes fall into two main types: Homogeneous TPO & Reinforced TPO. Reinforced TPO has a polyester mesh layer in the middle, which provides reinforced membranes with high breaking and tearing strength and puncture resistance."

Main Features of TPO Waterproof Membrane:

1. Manufactuer

2. Outstanding dimensional stability

3. High puncture resistance

4. Excellent chemical and environmental stress-cracking resistance

5. Good tensible strength

6. ISO and CE certificate

7. Easy to install

8. Customerized specification possible

Specifications of TPO Waterproof Membrane:

| Type | Thickness (mm) | Weight (kg/sqm) | Roll Size (m) | Colors | 20ft Container |

| Homogeneous TPO waterproof membrane | 1.0 mm | 1.63kg/sqm | 2.05m x 20m | White/ Grey | 340 rolls/ 14000 sqm |

| 1.2 mm | 1.83kg/sqm | 2.05m x 20m | White/ Grey | 285 rolls/ 12000 sqm | |

| 1.5 mm | 2.24kg/sqm | 2.05m x 20m | White/ Grey | 240 rolls/ 10000 sqm | |

| 2.0 mm | 2.30kg/sqm | 2.05m x 20m | White/ Grey | 215 rolls/ 9000 sqm | |

| Reinforced TPO waterproof membrane | 1.2 mm | 1.83kg/sqm | 2.05m x 20m | White/ Grey | 285 rolls/ 12000 sqm |

| 1.5 mm | 2.24kg/sqm | 2.05m x 20m | White/ Grey | 240 rolls/ 10000 sqm | |

| 2.0 mm | 2.30kg/sqm | 2.05m x 20m | White/ Grey | 215 rolls/ 9000 sqm |

Applications of TPO Waterproof Membrane:

- Roof construction & steel structure of both industrial and civil engineering

- Underground engineering, such as subways, tunnels, air Raid shelter, etc.

- Sewage treatment, dam, reservoir and basement, grain storehouse, etc.

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used in areas with high humidity?

- Yes, a waterproofing membrane can be used in areas with high humidity. In fact, high humidity can often contribute to the need for waterproofing as it can lead to moisture buildup and potential water damage. Waterproofing membranes are designed to create a barrier that prevents water from seeping through surfaces, such as walls or floors. They can effectively protect against moisture and water infiltration, which is particularly important in high humidity areas where the risk of water damage is greater. By applying a waterproofing membrane, you can significantly reduce the likelihood of mold, mildew, and other moisture-related issues in these environments.

- Q: Are waterproofing membranes flexible?

- Yes, waterproofing membranes are typically flexible. They are designed to be able to expand and contract with the building materials they are applied to, ensuring a tight and secure seal to prevent water penetration.

- Q: Can a waterproofing membrane be used for wastewater facilities?

- Yes, a waterproofing membrane can be used for wastewater facilities. Waterproofing membranes are specifically designed to protect structures from water damage, including from wastewater. These membranes are typically made of durable materials such as PVC, EPDM, or TPO, which have excellent resistance to water and chemicals. Wastewater facilities require robust protection against the corrosive and potentially damaging effects of wastewater. Installing a waterproofing membrane can help prevent water infiltration, which can lead to structural damage, deterioration, and contamination of surrounding areas. Waterproofing membranes provide a barrier that prevents water and moisture from penetrating the facility's walls, floors, and foundations. This helps to maintain the integrity of the structure, prevent leaks, and protect against corrosion caused by chemicals present in wastewater. In addition to protecting against water and chemical damage, some waterproofing membranes also offer resistance to UV rays, high temperatures, and freeze-thaw cycles, which are important considerations for wastewater facilities located in extreme weather conditions. Overall, using a waterproofing membrane in wastewater facilities is a reliable and effective solution to ensure long-term protection against water damage, maintain the structural integrity, and enhance the durability of the facility.

- Q: Can a waterproofing membrane be used in shower pans?

- Using a waterproofing membrane in shower pans is indeed recommended to prevent water leakage or damage to the underlying structure. This barrier prevents water from seeping through the shower pan and into the subfloor or surrounding walls, maintaining the integrity and longevity of the shower pan and the overall shower system. Furthermore, it also safeguards against mold and mildew growth, creating a safe and hygienic environment. Thus, incorporating a waterproofing membrane in shower pans is crucial for a durable and water-resistant shower installation.

- Q: Can waterproofing membranes be used on concrete slabs?

- Yes, waterproofing membranes can be used on concrete slabs. These membranes are designed to provide a protective barrier against water infiltration and can effectively prevent moisture from seeping into the concrete.

- Q: Are waterproofing membranes resistant to gasoline vapors?

- Yes, waterproofing membranes are generally resistant to gasoline vapors. They are designed to create a barrier against moisture and other liquids, including gasoline and its vapors.

- Q: Does a waterproofing membrane require any specific surface preparation for tile installations?

- Yes, a waterproofing membrane does require specific surface preparation for tile installations. The success of the waterproofing membrane and the longevity of the tile installation depend on proper surface preparation. Before installing a waterproofing membrane, it is crucial to ensure that the surface is clean, dry, and free from any contaminants such as dust, debris, oil, grease, or any loose or crumbling materials. The surface should be thoroughly cleaned and any existing tile, adhesive, or grout should be removed if necessary. In addition to cleanliness, it is important to make sure the surface is smooth and even. Any uneven areas or imperfections should be leveled and patched using a suitable patching compound. This will help prevent any water from pooling or seeping underneath the waterproofing membrane, which could lead to potential issues such as leaks, mold growth, or damage to the tile installation. Furthermore, it is essential to ensure that the surface is structurally sound and stable. If there are any cracks, weak areas, or signs of instability, they should be addressed and repaired before installing the waterproofing membrane. This will help provide a solid foundation for the tile installation and prevent any future problems. Overall, proper surface preparation is crucial for the success of a waterproofing membrane and tile installation. It ensures a clean, smooth, and stable surface, which is necessary for the membrane to adhere properly and provide effective waterproofing. Following the manufacturer's guidelines and consulting with a professional if needed can help ensure the correct surface preparation for a long-lasting and reliable tile installation.

- Q: Can a waterproofing membrane be used on different types of surfaces, such as concrete, wood, or metal?

- Yes, a waterproofing membrane can be used on different types of surfaces such as concrete, wood, or metal. Waterproofing membranes are designed to create a barrier that prevents water from penetrating the surface and causing damage. They are versatile and can adhere to various materials, making them suitable for different applications. For concrete surfaces, a waterproofing membrane can be applied to protect against water intrusion and to prevent moisture-related issues such as cracks, corrosion, or mold growth. It can be used on concrete foundations, basements, or retaining walls to ensure they remain dry and structurally sound. When it comes to wood, a waterproofing membrane acts as a protective layer that prevents water absorption, warping, rotting, or decay. It can be applied to exterior surfaces like decks, balconies, or fences to enhance their lifespan and maintain their integrity. In the case of metal surfaces, a waterproofing membrane can be used to prevent rusting and corrosion caused by water exposure. It creates a barrier that seals out moisture, protecting metal roofs, gutters, or other metal structures from water damage. It is important to note that different types of waterproofing membranes may be more suitable for specific surfaces. For example, liquid-applied membranes can be easily applied on irregular surfaces like concrete, while sheet membranes may be more appropriate for flat or smooth surfaces. It is advisable to consult with a professional or manufacturer to determine the most suitable waterproofing membrane for a specific surface and application.

- Q: Does a waterproofing membrane prevent water damage to building materials?

- Yes, a waterproofing membrane is designed to prevent water damage to building materials. It acts as a barrier that prevents water from penetrating into the structure and causing damage. The membrane is typically applied to areas that are susceptible to water intrusion, such as roofs, basements, and foundations. By creating a waterproof seal, it effectively prevents water from seeping through and damaging the building materials. This helps to protect the integrity of the structure and can prevent issues such as mold growth, rotting, and deterioration of materials. However, it is important to note that the effectiveness of a waterproofing membrane can vary depending on the quality of the product and the proper installation. Regular maintenance and inspections are also necessary to ensure that the membrane remains intact and continues to provide protection against water damage.

- Q: Does a waterproofing membrane provide any soundproofing benefits?

- No, a waterproofing membrane does not provide any soundproofing benefits. A waterproofing membrane is specifically designed to protect surfaces from water penetration, such as roofs, walls, or foundations. It is typically made of materials like asphalt, rubber, or polyethylene, which are not effective in blocking or absorbing sound waves. Soundproofing, on the other hand, involves the use of special materials and techniques that can reduce or eliminate the transmission of sound from one area to another. This can include insulation, acoustic panels, or soundproof barriers. Therefore, if soundproofing is a concern, it is necessary to consider separate soundproofing measures in addition to a waterproofing membrane.

Send your message to us

TPO Waterproof Membrane for Rooftop and Room

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords