Roof EPDM Waterproofing Membrane Width from 1.2mm to 2mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

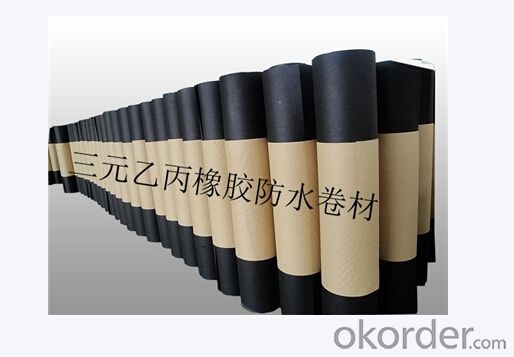

EPDM waterproofing membrane

1. Brief Introduction:

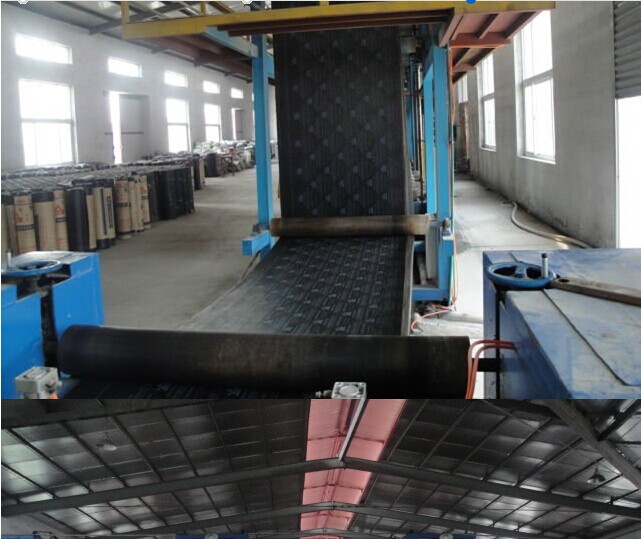

This waterproof membrane is made from ternary ethylene-propylene rubber. Weadopts the world advanced equipment of cold feeding extrusion and continuous valcanization technology.

With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or crack under normal building movement.

2. Characters:

1)Good flexibility, creep properties and malleability, and the superior adapting ability to the deformation of the primary stress generated.

2). Tight adhesion between waterproof layer and basic layer, no channeling water. Having self healing ability after piercing.

3).Operation without heating. And possessing the reliability of pasting by itself with super strong connection of sheet materialand adhesion of same base.

4). Convenient and safe operation, no pollution to the environment.

3. Application:

1),Roofs, Basement, Toilet

2),Industrial and civil building waterproofing

3),Geosynthetic liner for swimming pool, channels, irrigation system

4),Especially suit for projects with high requirements in durability, anti-corrosion anddeformation

4. Package and Storage:

Each Roll with one plastic bag with or without pallets.

Keep in dry and ventilated place. Avoid shining and raining. Height of stack not more than 5 layers. Shelf life:12 months.

5. Specification:

Type | EPDM Waterproof Rubber Membrane | |||

Material | EPDM Rubber | |||

Thickness | 1.0mm | 1.2mm | 1.5mm | 2.0mm |

Size | 1.2m(width) * 20m(length)/roll | |||

Type | Vulcanized | |||

Pattern | Non-reinforced(homogeneous) | |||

Packing | 24sqm--80sqm/roll, with plastic bag | |||

Color | Black | |||

Application | Roofs, basement, pond, Lake, steel structure roof, swimming pool, underground, tunnel, etc | |||

5. Some photos:

- Q: Can a waterproofing membrane be used in roofs?

- Roofs can indeed benefit from the use of a waterproofing membrane. It's a widely employed technique for safeguarding roofs against water-related harm. Typically composed of robust materials like rubber or modified bitumen, this membrane is applied to the roof's surface to establish a barrier that prevents water from seeping through. As a result, leaks and potential damage are averted, as this protective layer stops water from penetrating the roof's underlying structure. Waterproofing membranes are particularly advantageous for flat or low-sloped roofs, where water accumulation is prone to causing issues. Moreover, these versatile membranes can be utilized on diverse roofing materials, including concrete, metal, and asphalt, making them suitable for various roof types. Overall, incorporating a waterproofing membrane into roofs effectively enhances their durability and longevity, while ensuring dependable protection against water infiltration.

- Q: Can a waterproofing membrane be used for elevator shafts and stairwells?

- Yes, a waterproofing membrane can be used for elevator shafts and stairwells to provide a barrier against water infiltration and prevent moisture-related damages.

- Q: Can a waterproofing membrane be used for parking garage ramps and driveways?

- Yes, a waterproofing membrane can be used for parking garage ramps and driveways. It serves as a protective barrier against water infiltration, preventing damage to the underlying structure and extending its lifespan.

- Q: Is a waterproofing membrane resistant to impact damage?

- The main purpose of a waterproofing membrane is not to withstand impact damage. Rather, it is primarily intended to safeguard the underlying structure from moisture damage and prevent water infiltration. Although certain membranes may possess a certain degree of impact resistance, it is not their principal attribute. In order to shield the membrane from impact damage, additional precautions such as incorporating protective layers or utilizing materials that are resistant to impact may be required.

- Q: Can a waterproofing membrane be used on flat roofs?

- Yes, a waterproofing membrane can be used on flat roofs. In fact, it is a common and effective method used to protect flat roofs from water damage and leakage. The waterproofing membrane is designed to provide a durable and watertight barrier, ensuring the roof remains protected from rain, snow, and other elements.

- Q: Can a waterproofing membrane be used on precast aluminum surfaces?

- Yes, a waterproofing membrane can be used on precast aluminum surfaces. The membrane forms a protective layer that prevents water penetration, ensuring the durability and longevity of the precast aluminum surfaces.

- Q: How long do waterproofing membranes last?

- The lifespan of waterproofing membranes can differ based on a variety of factors including the type of membrane utilized, the quality of installation, environmental conditions, and maintenance practices. Typically, high-quality waterproofing membranes have a lifespan ranging from 10 to 50 years. As an illustration, bituminous membranes, commonly employed in roofing applications, generally last around 20 to 30 years. Conversely, more advanced synthetic membranes like PVC or TPO can endure for up to 40 years or possibly longer. Nevertheless, it is essential to recognize that these estimates are contingent upon optimal conditions and regular maintenance. Factors such as exposure to extreme weather, improper installation, insufficient maintenance, or physical damage can significantly diminish the lifespan of the membranes. Consequently, it is vital to seek guidance from professionals and adhere to the manufacturer's maintenance recommendations in order to ensure the longevity of the waterproofing membranes.

- Q: Can a waterproofing membrane be used in hot climates?

- Yes, a waterproofing membrane can be used in hot climates. In fact, it is essential to use a waterproofing membrane in areas with high temperatures and intense sunlight. The membrane provides protection against water intrusion, which is crucial in preventing damage to structures such as roofs, balconies, or basements. Additionally, a high-quality waterproofing membrane is designed to withstand the effects of temperature fluctuations and UV radiation, ensuring its longevity and effectiveness even in hot climates. Therefore, using a waterproofing membrane is highly recommended in hot climates to ensure the durability and integrity of the structures it is applied to.

- Q: What is the difference between PET waterproofing membrane and BAC waterproofing membrane? What is the commonality? Is BAC a PET?

- PET refers to polyethylene terephthalate, PET film using polyester composite film as the surface material, coated with rubber asphalt adhesive material, with cement mortar paste or self-adhesive. Can be constructed on the wet base surface, the grass-roots requirements are low, with high bond strength, bonding effect is good, not channeling water and so on.

- Q: Does a waterproofing membrane provide any soundproofing benefits?

- No, a waterproofing membrane does not provide any soundproofing benefits. Its primary function is to prevent water penetration and protect against moisture damage. Soundproofing requires specific materials and techniques designed to absorb, block, or isolate sound waves.

Send your message to us

Roof EPDM Waterproofing Membrane Width from 1.2mm to 2mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords