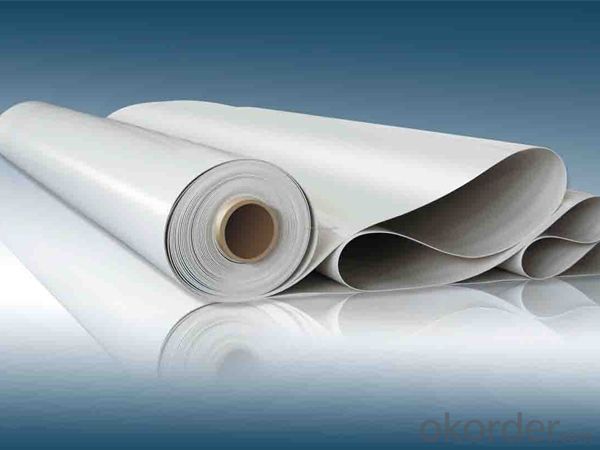

TPO Roofing Waterproof Membrane with Superior Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The Advantages Of TPO Roofing Waterproof Membrane with Superior Material:

1. Weather resistance and durability

2. Excellent weldability

3. No any crisp agents to prevent materials brittleness

4. Intermediate enhanced polyester mesh fabric to have high tensile strength, fatigue resistance and penetrating resistance suitable for mechanically attached roofing systems

5. Excellent high and low temperature resistance the same as rubber materials which can keep flexible at -50 degree and keep mechanical strength in high temperature

6. Excellent chemical resistance to acids, bases, restaurant exhaust emissions, etc.

7. Dimension stability

8. White-based light-color and smooth surface with high reflection, energy saving and anti-dust functions

9. Use heat welding for the seam areas to form a reliable seamless waterproof layer

Applications of TPO Roofing Waterproof Membrane with Superior Material:

- Roof construction & steel structure of both industrial and civil engineering

- Underground engineering, such as subways, tunnels, air Raid shelter, etc.

- Sewage treatment, dam, reservoir and basement, grain storehouse, etc."

Technical Parameters of TPO Roofing Waterproof Membrane with Superior Material:

No. | Item | Index | |||

1 | mm≥ thickness of resin layer above inermediate tire mm ≥ | - | - | 0.4 | |

2 | tensile property | N/cm ≥ maximum tensile force N/cm ≥ | - | 200 | 250 |

MPa ≥ tensile Strength MPa ≥ | 12.0 | - | - | ||

≥ elongation at maximun tensile force% ≥ | - | - | 15 | ||

% ≥ elongation at fracture % ≥ | 500 | 250 | - | ||

3 | size change rate under heat treatment %≤ | 2.0 | 1.0 | 0.5 | |

4 | flexibility at low temperature | no crack at -40°c | |||

5 | unpermeability | 0.3Mpa,2h waterproof | |||

FRQ:

What is your main market?

Our Tpo Roofing Membrane with Superior Raw Material for Roofing Market sells very well in USA, United Kingdom, Austrilia, Canada, Japan, Pakistan, etc.

What is your advantage for Tpo Roofing Membrane?

With the most advanced production line, our good quality is based on superior material imported from America. We have different color available and could produce any color you want.

- Q: Can a waterproofing membrane be used on EPDM roofs?

- Yes, a waterproofing membrane can be used on EPDM roofs. EPDM (ethylene propylene diene terpolymer) is a highly durable and flexible synthetic rubber roofing material commonly used for low-slope and flat roofs. While EPDM roofs are already waterproof, applying an additional waterproofing membrane can provide an extra layer of protection and enhance the roof's longevity. The waterproofing membrane can act as a barrier against water infiltration, preventing leaks and moisture damage. However, it is important to ensure that the waterproofing membrane is compatible with EPDM and follows the manufacturer's guidelines for installation to maintain the roof's integrity.

- Q: Is a waterproofing membrane resistant to algae or moss growth?

- A waterproofing membrane is usually resistant to the growth of algae or moss. Its purpose is to form a barrier against water infiltration, preventing moisture from seeping into the underlying structure. These membranes are typically composed of materials that are not favorable for the growth of algae or moss, such as synthetic polymers or rubberized compounds. Furthermore, they are often treated with additives that hinder the growth of organic matter, including algae or moss. Nevertheless, it is crucial to acknowledge that if the membrane is consistently exposed to moisture or damp conditions over time, it may become a breeding ground for algae or moss. Therefore, it is important to regularly maintain and clean the waterproofing membrane to ensure its longevity and effectiveness.

- Q: Can a waterproofing membrane be used on roofs with rooftop gardens?

- Yes, a waterproofing membrane can be used on roofs with rooftop gardens. In fact, it is highly recommended to use a waterproofing membrane to protect the underlying structure from water damage. A rooftop garden adds additional weight and moisture to the roof, so a proper waterproofing system is essential to prevent leaks and ensure the longevity of the roof. The waterproofing membrane acts as a barrier against water infiltration and helps to keep the rooftop garden and the building below dry.

- Q: Are waterproofing membranes resistant to earthquake movements?

- Waterproofing membranes are designed to prevent the intrusion of water and moisture into structures, such as buildings and basements. While they are highly effective in protecting against water damage, they are not specifically designed to resist or withstand earthquake movements. Earthquakes involve the shaking and movement of the ground, which can exert significant forces on structures. Waterproofing membranes are not typically engineered to absorb or distribute these forces in the same way as seismic-resistant materials or building techniques. However, it is worth noting that some waterproofing systems may have a certain degree of flexibility or elasticity, which could potentially provide some resistance to minor ground movements during an earthquake. These properties may help the membrane to maintain its integrity and prevent water intrusion in the event of slight shifting or settling. Ultimately, when it comes to earthquake resistance, it is crucial to employ specialized seismic design principles and techniques that are appropriate for the specific location and building requirements. Waterproofing membranes should be used in conjunction with these seismic-resistant measures to ensure the overall structural integrity and safety of a building during seismic events.

- Q: Can a waterproofing membrane be used for a hospital?

- Yes, a waterproofing membrane can be used for a hospital. Waterproofing membranes are commonly used in hospitals to prevent water infiltration and protect the building from water-related damages. They are especially useful in areas with high moisture levels such as bathrooms, basements, and roofs. By installing a waterproofing membrane, hospitals can ensure a dry and safe environment for both patients and staff, reducing the risk of mold, mildew, and structural deterioration caused by water damage.

- Q: Can waterproofing membranes be used on concrete surfaces?

- Yes, waterproofing membranes can be used on concrete surfaces. Waterproofing membranes are designed to create a barrier against water penetration, and they are commonly used on concrete surfaces to protect them from water damage. These membranes are typically made of materials such as rubber, PVC, or bitumen, and they are applied to the concrete surface in a liquid or sheet form. Once applied, the membrane forms a continuous and durable waterproof layer that prevents water from seeping into the concrete. This is particularly beneficial in areas that are prone to water exposure, such as basements, bathrooms, or exterior concrete structures. Waterproofing membranes can effectively extend the lifespan of concrete surfaces by preventing water-related issues such as cracking, spalling, or mold growth.

- Q: Does a waterproofing membrane need to be primed before installation?

- Yes, a waterproofing membrane typically requires priming before installation. Priming helps improve the adhesion of the membrane to the substrate and ensures proper bonding, enhancing the overall effectiveness and durability of the waterproofing system.

- Q: Are waterproofing membranes resistant to chemicals?

- Yes, waterproofing membranes are generally resistant to chemicals. These membranes are designed to provide a protective barrier against water infiltration and are typically made from materials such as PVC, TPO, or EPDM which have excellent chemical resistance properties. They are specifically engineered to withstand exposure to various chemicals, including acids, alkalis, solvents, and oils, without deteriorating or being damaged. This chemical resistance ensures that waterproofing membranes can maintain their integrity and effectiveness in environments where chemical exposure is common, such as industrial settings, laboratories, or chemical storage areas. However, it is important to note that the specific chemical resistance capabilities can vary depending on the type and quality of the waterproofing membrane, so it is crucial to choose the appropriate membrane that suits the specific chemical exposure requirements of the project.

- Q: Can a waterproofing membrane be used for planter boxes or green roofs?

- Certainly, planter boxes or green roofs can benefit from the utilization of a waterproofing membrane. It is strongly advised to implement a waterproofing membrane in these scenarios in order to avoid any water seepage or harm to the underlying structure. Essentially acting as a safeguard, the waterproofing membrane serves to prevent water infiltration into the planter boxes or green roofs, therefore preventing potential complications like decay, mold, or structural deterioration. By skillfully sealing the area, the waterproofing membrane guarantees that the water remains within the designated area, which in turn fosters robust plant growth and safeguards the structural stability.

- Q: Can a waterproofing membrane be used on terrazzo surfaces?

- Yes, a waterproofing membrane can be used on terrazzo surfaces. Terrazzo is a durable and long-lasting material, but it is porous and can absorb water if left untreated. Applying a waterproofing membrane helps protect the terrazzo surface from moisture damage, preventing water penetration and potential issues such as staining, cracking, or mold growth.

Send your message to us

TPO Roofing Waterproof Membrane with Superior Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords