Thermoplastic Polyolefin (TPO)Roofing Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of Thermoplastic Polyolefin (TPO)Roofing Membrane:

Thermoplastic polyolefin (TPO) membrane is based on polypropylene and EP (ethylene-propylene) rubber polymerized together by using state-of-the-art polymer manufacturing technology. This technology enables BAIRUI TPO membranes flexible at low temperatures without the use of polymeric or liquid plasticizers. BAIRUI TPO membranes fall into two main types: Homogeneous TPO & Reinforced TPO. Reinforced TPO has a polyester mesh layer in the middle, which provides reinforced membranes with high breaking and tearing strength and puncture resistance."

Features of Thermoplastic Polyolefin (TPO)Roofing Membrane:

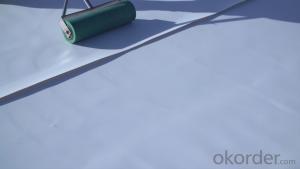

- Easy installation with good system integrity, need few accessories

- High tensile and tear strength, puncture resistance

- No plasticizer, heat aging and UV resistance, durable

- Hot-air welding, rapid welding speed, high peel strength (two times of PVC)

-No chlorine, 100% recyclable, environment friendly

- Durable hot-air welding performance and convenient maintainance

- Smooth surface, unfading and stain resistance

Applications of Thermoplastic Polyolefin (TPO)Roofing Membrane:

- Roof construction & steel structure of both industrial and civil engineering

- Underground engineering, such as subways, tunnels, air Raid shelter, etc.

- Sewage treatment, dam, reservoir and basement, grain storehouse, etc."

Data Sheet of Thermoplastic Polyolefin (TPO)Roofing Membrane:

Type | Thickness (mm) | Weight (kg/sqm) | Roll Size (m) | Colors | 20ft Container |

Homogeneous TPO waterproof membrane | 1.0 mm | 1.63kg/sqm | 2.05m x 20m | White/ Grey | 340 rolls/ 14000 sqm |

1.2 mm | 1.83kg/sqm | 2.05m x 20m | White/ Grey | 285 rolls/ 12000 sqm | |

1.5 mm | 2.24kg/sqm | 2.05m x 20m | White/ Grey | 240 rolls/ 10000 sqm | |

2.0 mm | 2.30kg/sqm | 2.05m x 20m | White/ Grey | 215 rolls/ 9000 sqm | |

Reinforced TPO waterproof membrane | 1.2 mm | 1.83kg/sqm | 2.05m x 20m | White/ Grey | 285 rolls/ 12000 sqm |

1.5 mm | 2.24kg/sqm | 2.05m x 20m | White/ Grey | 240 rolls/ 10000 sqm | |

2.0 mm | 2.30kg/sqm | 2.05m x 20m | White/ Grey | 215 rolls/ 9000 sqm |

FRQ:

What is your main market?

Our Tpo Roofing Membrane with Superior Raw Material for Roofing Market sells very well in USA, United Kingdom, Austrilia, Canada, Japan, Pakistan, etc.

What is your advantage for Tpo Roofing Membrane?

With the most advanced production line, our good quality is based on superior material imported from America. We have different color available and could produce any color you want.

- Q: Can a waterproofing membrane be used for a bridge deck construction?

- Yes, a waterproofing membrane can be used for bridge deck construction. Waterproofing membranes are commonly used in bridge deck construction to protect the underlying structure from water infiltration, which can cause corrosion and damage over time. The membrane acts as a barrier to prevent water from seeping into the concrete, ensuring the durability and longevity of the bridge deck.

- Q: Can a waterproofing membrane be used for water treatment plants?

- Yes, a waterproofing membrane can be used for water treatment plants. Waterproofing membranes are designed to prevent the passage of water and can be used to provide a barrier against water leakage in various structures, including water treatment plants. These membranes can be applied to different areas of the plant, such as tanks, reservoirs, pipes, and basements, to prevent water infiltration and protect the infrastructure from potential damage. Additionally, waterproofing membranes can help maintain the integrity of the water treatment process by ensuring that water remains contained within designated areas and does not seep into surrounding soil or structures.

- Q: Can a waterproofing membrane be installed on any surface?

- A waterproofing membrane can generally be installed on a variety of surfaces, but there are some factors to consider. The suitability of the surface depends on its condition, composition, and the type of waterproofing membrane being used. Typically, waterproofing membranes are designed to adhere to various substrates such as concrete, wood, metal, and masonry. They can be applied to surfaces like roofs, foundations, basements, bathrooms, and balconies. However, it is crucial to ensure that the surface is clean, dry, and free from any contaminants, such as dirt, debris, or loose materials, before installing the membrane. Furthermore, certain surfaces may require additional preparatory work or primers to enhance adhesion and ensure a long-lasting waterproofing solution. For example, rough or uneven surfaces might need to be leveled or smoothed out before the membrane can be applied. It is also important to consider the specific requirements of the waterproofing system being used. Different membranes have different application methods and compatibility with different surfaces. Some membranes may be more suitable for horizontal surfaces like flat roofs, while others may be better suited for vertical surfaces such as walls or foundations. Ultimately, it is recommended to consult with a professional waterproofing contractor or refer to the manufacturer's guidelines to determine the compatibility of the waterproofing membrane with a specific surface and to ensure proper installation for optimal performance and longevity.

- Q: How does a waterproofing membrane handle cracks in the substrate?

- A waterproofing membrane is designed to handle cracks in the substrate by providing a barrier that prevents water from penetrating through the cracks. The membrane is typically made of a flexible material, such as rubber or synthetic polymers, which allows it to stretch and move with the substrate without tearing or breaking. When cracks occur in the substrate, the membrane is able to bridge over the cracks and maintain its integrity, preventing water from seeping through. In some cases, the membrane may have a self-healing property, where it can seal minor cracks on its own, ensuring continuous protection against water ingress. To further enhance its crack-bridging capability, the waterproofing membrane may be reinforced with fibers or fabric layers. These reinforcements increase the tensile strength and flexibility of the membrane, allowing it to effectively span larger cracks or accommodate movement in the substrate without compromising its waterproofing performance. It is important to note that the extent to which a waterproofing membrane can handle cracks in the substrate depends on various factors, such as the type and size of the cracks, the movement of the substrate, and the quality of the membrane installation. It is essential to follow the manufacturer's guidelines and ensure proper surface preparation and installation techniques to maximize the membrane's ability to handle cracks and provide long-lasting waterproofing protection.

- Q: Does a waterproofing membrane require any special considerations for installation in high-humidity areas?

- Yes, a waterproofing membrane does require special considerations for installation in high-humidity areas. High humidity can increase the moisture levels that the membrane is exposed to, potentially affecting its performance and durability. It is important to choose a membrane specifically designed for high-humidity environments and follow proper installation techniques to ensure effective moisture protection. Additionally, regular inspections and maintenance should be conducted to prevent any potential damage or deterioration caused by the high humidity.

- Q: Can a waterproofing membrane be used for vehicular traffic areas?

- Yes, a waterproofing membrane can be used for vehicular traffic areas. Waterproofing membranes are designed to protect surfaces from water damage by creating a barrier that prevents water from seeping through. In vehicular traffic areas, such as parking decks or driveways, it is important to protect the underlying structure from water infiltration, which can cause corrosion, deterioration, and expensive repairs. By using a waterproofing membrane specifically designed for vehicular traffic, the surface can be adequately protected from water damage, as well as other potential contaminants like oil and chemicals. These membranes are typically more durable and able to withstand the weight and impact of vehicles, ensuring long-lasting protection. Additionally, some waterproofing membranes offer slip-resistant properties, making them suitable for use in areas where vehicles may need traction. However, it is crucial to consult with a professional to determine the appropriate waterproofing membrane and installation method for specific vehicular traffic areas based on factors such as traffic volume, load capacity, and climate conditions.

- Q: Can a waterproofing membrane be used in kitchens?

- Yes, a waterproofing membrane can be used in kitchens. Waterproofing membranes are commonly used in areas prone to moisture, such as bathrooms and kitchens, to prevent water damage and leakage. They can be applied to various surfaces, including floors and walls, to create a waterproof barrier and protect against water infiltration. By using a waterproofing membrane in kitchens, one can ensure the longevity and durability of the space while preventing potential water-related issues.

- Q: Can a waterproofing membrane be used for plant rooms and mechanical equipment areas?

- Yes, a waterproofing membrane can be used for plant rooms and mechanical equipment areas. These areas often require protection from water and moisture damage, and a waterproofing membrane can provide an effective barrier to prevent leaks and water infiltration.

- Q: Basement SBS Waterproof Coil Division I and II type What is the difference? How is the site identified?

- SBS type I and type II differences are mainly low temperature flexibility and tensile extension. Type I low temperature flexibility is -20 degrees, pulling force of 500N / 5cm, elongation of 30%. Type II low temperature is -25 degrees, tension of 800N / 5cm, elongation of 40%. The appearance of the general can not distinguish, you can do experiments.

- Q: Are waterproofing membranes resistant to hydrostatic pressure?

- Yes, waterproofing membranes are designed to be resistant to hydrostatic pressure. Hydrostatic pressure refers to the pressure exerted by water when it is at rest. When a building is exposed to water from the ground, such as in basements or foundations, hydrostatic pressure can become a significant concern, as it can cause water to seep through the walls or floors. Waterproofing membranes are specifically engineered to withstand and resist the pressure exerted by water, ensuring that it does not penetrate into the building structure. These membranes are typically made from materials such as bitumen, rubberized asphalt, or synthetic polymers, which have excellent water resistance properties. Moreover, waterproofing membranes are designed to create a continuous barrier against water, preventing any potential leaks or seepage. They are applied in multiple layers, ensuring a strong and durable barrier that can withstand the high pressure exerted by water. It is important to note that the resistance to hydrostatic pressure may vary depending on the type and quality of the waterproofing membrane used. Therefore, it is crucial to choose a high-quality membrane and ensure proper installation to maximize its effectiveness in resisting hydrostatic pressure.

Send your message to us

Thermoplastic Polyolefin (TPO)Roofing Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords