Self-adhesive Modified Bitumen Waterproofing Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 60000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Self-adhesive Modified Bitumen Waterproofing Membrane:

Self Adhesive Bitumen Waterproof Membrane

Introduction of Self-adhesive Modified Bitumen Waterproofing Membrane:

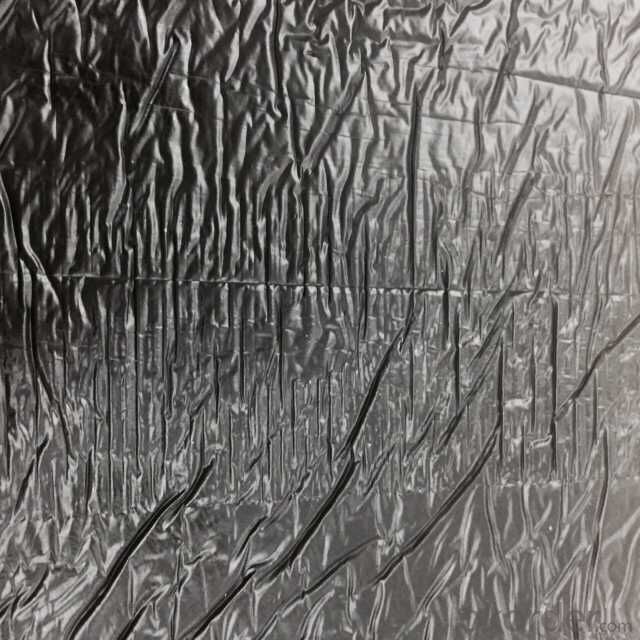

SBS(Styrene Butadiene Styrene) /APP (Atactic Polypropylene) modified bitumen membrane is made by saturating the base in bitumen, or thermoplastic elastomer (such as SBS, APP, APAO, APO), reinforced with polyester or fiberglass, finishing the upward face with polythene membrane, fine sands or mineral slates (or grains) or etc.

Specification of Self-adhesive Modified Bitumen Waterproofing Membrane:

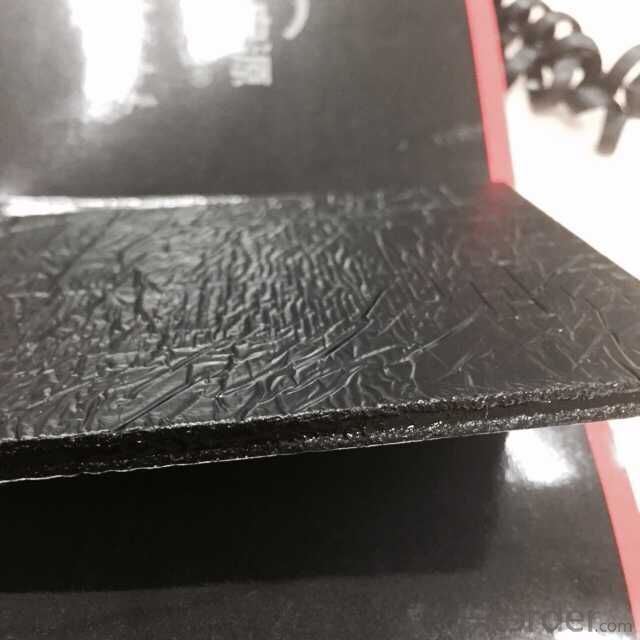

Thickness | 3mm, 4mm, 5mm |

Width | 1m |

length | 7.5m, 10m, 15m, or on demand |

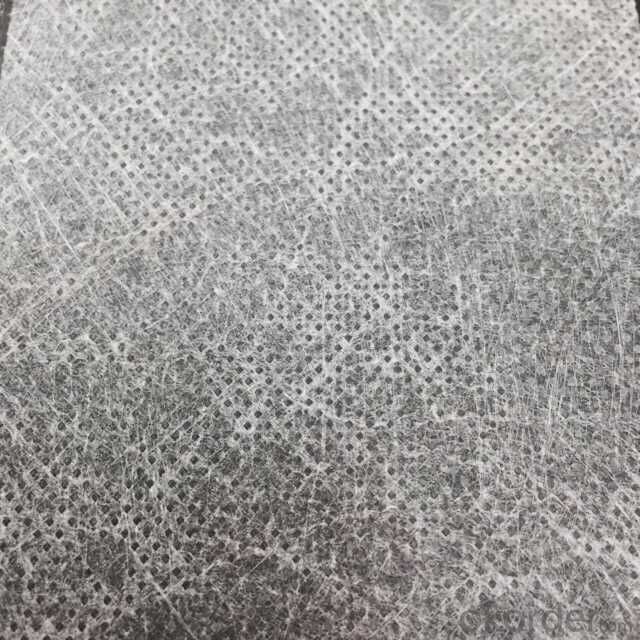

Base | Polyester or Fiberglass felt |

Surface | PE film, Aluminum foil, Yellow sand, Shale gravel(Schist), colored sand |

Type | could self-adhesive |

Notice | SBS modified bitumen membrane is specially applied in the cold district, APP modified bitumen membrane is more suitable for hot district with high temperature. could be self-adhesive modified bitumen membrane |

Applications of Self-adhesive Modified Bitumen Waterproofing Membrane:

-Roof and underground in industrial and civil buildings;

-Bridge, subway, tunnel, swimming pool, etc.

-Waste landfill, sewage plant, irrigation system, etc.

-Self-adhesive Modified Bitumen Waterproof Membrane

-Easy applying and economic on the cost saving

Advantage of Self-adhesive Modified Bitumen Waterproofing Membrane:

-Non-solidified, excellent elastic deformation,thus have good noise reducing;

-Easy applying and economic on the cost saving.

-Good performance on waterproof and economic sound damping.

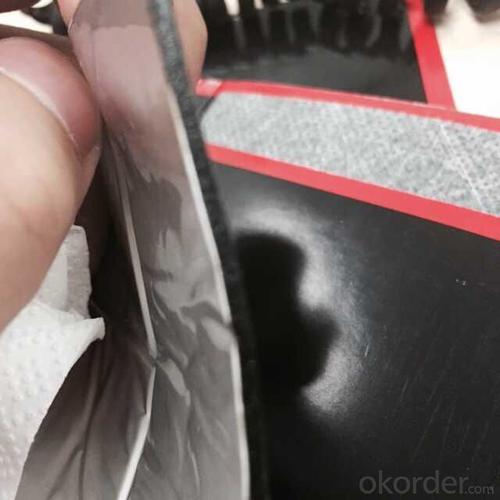

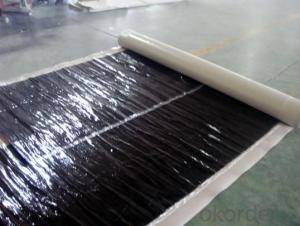

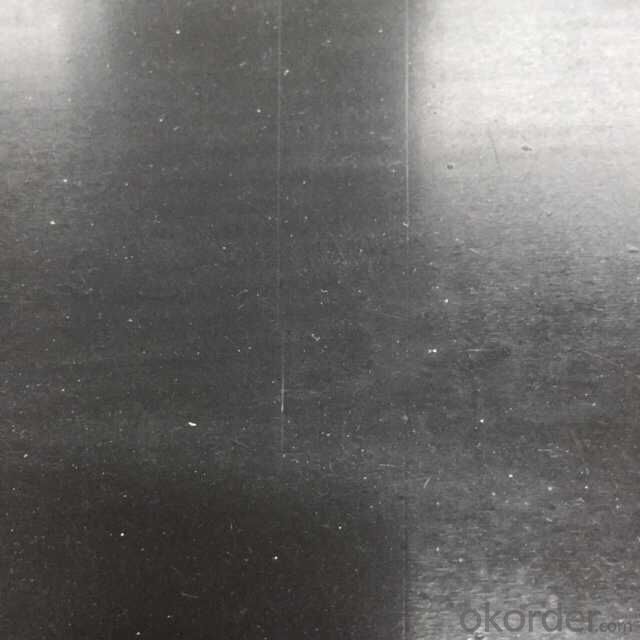

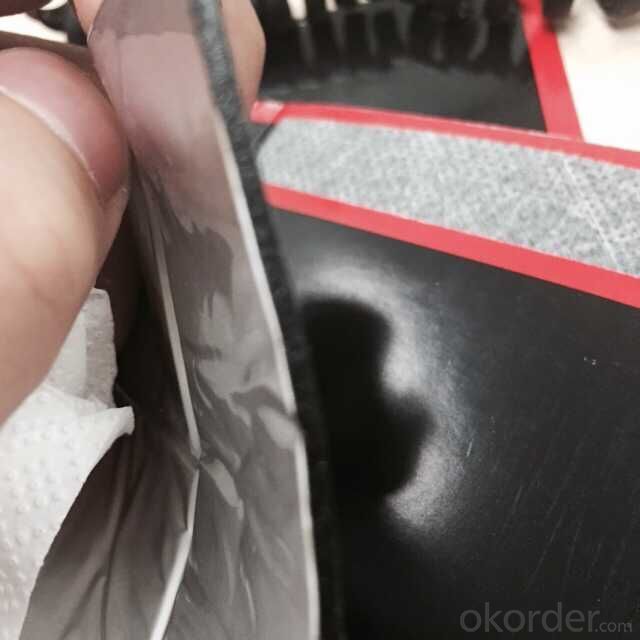

Picture of Self-adhesive Modified Bitumen Waterproofing Membrane:

Storage of Self-adhesive Modified Bitumen Waterproofing Membrane:

Shelf life is 12 months. Store in a cool and dry place with original packing.

Breathable Waterproof Roof Underlay membrane (PP-PP,S-PP,S-S)

Permeable membrane is polymer modified asphalt based, with surface of high strength polypropylene fiber. Back side coated with self adhesive glue or antiskid sand. Made by special process. With excellent waterproof performance and breathable properties.\

Description | Specification | Width | Length | Thickness | |

Roof underlay | 500g/m2PP—PP | 1000mm | 30m | 0.8mm | |

600g/m2S—PP | 1000mm | 25m | 1.0mm | ||

1500g/m2S—S | 1000mm | 20m | 1.3mm | ||

Roof underlay with adhesive band | 500g/m2PP—PP | 1000mm | 30m | 0.8mm | |

600g/m2S—PP | 1000mm | 25m | 1.0mm | ||

1500g/m2S—S | 1000mm | 20m | 1.3mm | ||

It is used as the underlayment of cement tile, painted pottery watts and asphalt shingle. Also suitable for all kinds of architectural roofing, walls, underground waterproof and damp proof project.

Features:

It has good waterproofing and ageing-resistance function,not flowing at highest temperature and no crack at lowest temperature;

Easy application,no pollution,and long service life etc.

Usage:

It is widely used for industry and civil building --- the waterproof and dampproof of the roofs,basements,toilets etc;and the waterproofing of bridges,parking area,tunnels,reserviors etc.

It is specially suitable to the building waterproofing in cold area and to the buildings of changeable constructions.

Requirements for surroundings

-The base should be dry and clean. Do not work in the rainy or snowy day.

-Do not work under heavy wind(above 5 grade)

-Unsuitable for construction below 0°C

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can waterproofing membranes be painted over?

- Yes, waterproofing membranes can be painted over. However, it is important to use a paint that is compatible with the membrane material and to ensure that the membrane is clean and dry before painting. Additionally, it is advisable to consult the manufacturer's guidelines or seek professional advice to ensure proper adhesion and longevity of the painted surface.

- Q: Are waterproofing membranes resistant to sulfuric acid exposure?

- Yes, waterproofing membranes are generally resistant to sulfuric acid exposure. These membranes are designed to provide a barrier against water and other chemicals, including sulfuric acid. However, the level of resistance may vary depending on the specific type and quality of the membrane. It is advisable to consult with manufacturers or experts to ensure the membrane's compatibility with sulfuric acid exposure in specific applications.

- Q: Can a waterproofing membrane be used for stadiums or arenas?

- Yes, a waterproofing membrane can definitely be used for stadiums or arenas. In fact, it is highly recommended to use waterproofing membranes in these large-scale structures to protect them from water damage and leaks. Stadiums and arenas are often exposed to various weather conditions, including heavy rain and snow, which can potentially cause water infiltration into the structure. A waterproofing membrane acts as a barrier, preventing water from penetrating the building envelope and causing damage to the structural components, such as concrete or steel. It helps to maintain the integrity of the structure and prolong its lifespan. Additionally, waterproofing membranes can also provide protection against other forms of moisture, such as condensation and humidity, which can lead to mold growth and deterioration of materials. Therefore, using a waterproofing membrane is a crucial step in ensuring the durability and longevity of stadiums and arenas.

- Q: Are there any specific installation requirements for waterproofing membranes?

- Yes, there are specific installation requirements for waterproofing membranes. These requirements may vary depending on the type of membrane being used, but there are some general guidelines that apply to most installations. Firstly, it is important to properly prepare the surface that the membrane will be applied to. This may involve cleaning the surface, removing any loose debris or previous coatings, and ensuring the surface is smooth and free from any irregularities. This step is crucial as it allows for better adhesion between the membrane and the surface. Next, the membrane should be applied according to the manufacturer's instructions. This typically involves using a suitable adhesive or bonding agent to adhere the membrane to the surface. It is important to follow the recommended application rate and ensure that the membrane is applied evenly and without any air bubbles or wrinkles. In addition to proper application, it is also important to pay attention to the seams and joints of the membrane. These areas are particularly vulnerable to water penetration, so they should be carefully sealed using an appropriate sealant or tape. This ensures a watertight seal and prevents any water from seeping through the seams. Lastly, it is important to protect the installed membrane from any damage during and after installation. This may involve covering the membrane with a protective layer, such as a geotextile fabric or a layer of soil, to prevent punctures or tears. Additionally, any construction or landscaping work that may occur after the installation should be done with caution to avoid damaging the membrane. Overall, the specific installation requirements for waterproofing membranes will depend on the type of membrane being used and the specific conditions of the project. It is always recommended to consult the manufacturer's instructions and guidelines to ensure proper installation and long-lasting waterproofing performance.

- Q: Can a waterproofing membrane be used on precast stainless steel surfaces?

- Yes, a waterproofing membrane can be used on precast stainless steel surfaces. Waterproofing membranes are designed to create a barrier against water penetration, regardless of the substrate material. The membrane can be applied directly to the stainless steel surface to provide protection against moisture, preventing leaks and potential damage. It is important to select a suitable waterproofing membrane that is compatible with stainless steel and has good adhesion properties. Additionally, proper surface preparation and application techniques should be followed to ensure optimal performance of the membrane.

- Q: Is a waterproofing membrane resistant to hydrocarbons or oil spills?

- Yes, a waterproofing membrane is generally resistant to hydrocarbons or oil spills.

- Q: Can a waterproofing membrane be used for sealing pipe penetrations?

- Yes, a waterproofing membrane can be used for sealing pipe penetrations. Waterproofing membranes are designed to create a barrier against water and moisture, making them suitable for sealing pipe penetrations to prevent water leakage or intrusion.

- Q: Can a waterproofing membrane be used in stadiums or sports complexes?

- Stadiums and sports complexes can indeed benefit from the use of waterproofing membranes. It is highly advisable to employ waterproofing solutions in these types of structures to safeguard them against water damage and leaks. The purpose of a waterproofing membrane is to serve as a barrier, preventing water from infiltrating the concrete or other construction materials employed in the stadium or sports complex. This is especially crucial in regions where heavy rainfall or high humidity levels are prevalent. Implementation of a waterproofing membrane on the roofs, walls, and foundations of these edifices helps guarantee their longevity and structural integrity, while also offering a comfortable and secure environment for athletes and spectators alike. Waterproofing membranes are specifically designed to endure the pressures and movements associated with the building, making them an optimal choice for stadiums and sports complexes. Additionally, contemporary waterproofing membranes come in diverse forms, including liquid-applied or sheet membranes. This allows for flexibility in application and compatibility with various construction materials.

- Q: Are there any specific building code requirements for waterproofing membranes?

- Yes, there are specific building code requirements for waterproofing membranes. Building codes vary by jurisdiction, but most codes require that waterproofing membranes meet certain standards and specifications. These requirements are put in place to ensure that buildings are adequately protected from water damage and to maintain the safety and integrity of the structure. Some common building code requirements for waterproofing membranes include: 1. Material standards: The building code may specify the type of materials that can be used for waterproofing membranes. This can include specifications for the type of membrane, such as liquid-applied or sheet membranes, as well as the required thickness and composition. 2. Installation standards: The building code may outline specific installation methods and techniques for waterproofing membranes. This can include requirements for proper surface preparation, application procedures, and detailing around penetrations and transitions. 3. Testing and certification: Building codes may require that waterproofing membranes undergo certain tests and meet specific performance criteria. This can include tests for resistance to water penetration, durability, and compatibility with other building materials. In some cases, the code may require that the waterproofing membrane be certified by a recognized testing laboratory. 4. Code compliance documentation: Building codes often require that waterproofing membranes be installed in accordance with approved plans and specifications. This means that contractors may need to submit documentation to demonstrate compliance with the code, such as product data sheets, manufacturer's installation instructions, and details of the proposed waterproofing system. It is important to consult the local building code or regulatory authority to determine the specific requirements for waterproofing membranes in a particular jurisdiction. Compliance with these requirements is essential to ensure the proper functioning and longevity of the waterproofing system and to avoid potential issues such as water intrusion, mold growth, and structural damage.

- Q: Can waterproofing membranes be used on below-grade parking structures?

- Yes, waterproofing membranes can be used on below-grade parking structures. These membranes are designed to prevent water infiltration and protect the structure from potential water damage. They are commonly used in below-grade applications to ensure the longevity and structural integrity of the parking facility.

Send your message to us

Self-adhesive Modified Bitumen Waterproofing Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 60000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords