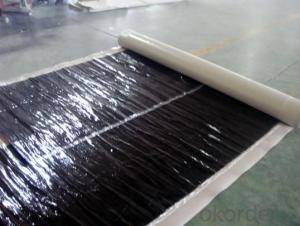

Self Adhesive Modified Bituminous Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

itis a modified bitumen base sheet consisting of polymer modified asphalt added viscosifier inside covering with different upper separated materials and underside with silicone antisticking layer. According to different upper surface, it includes three types: PE film surfacing (SAM-930APE), sand surfacing (SAM-930AS) and antisticking surfacing (SAM-930AN). There have two kinds of thickness: 3.0 mm and 4.0 mm.

Item | Requirement | ||

Soluble matter content, g/m 2 ≥ | 3 mm | 2100 | |

4 mm | 2900 | ||

Tensile property | Tensile strength, N/50mm ≥ | 3 mm | 600 |

4 mm | 800 | ||

Elongation at the maximum tensile force, % ≥ | 40 | ||

Resistance to heat( degree centigrade ) | 70, No sliding, flowing, dripping | ||

Flexibility at low temperature,( degree centigrade ) | -30 | ||

No cracking | |||

Water tightness | Pass at 0.3 MPa, 120 min | ||

Sheering properties N/50mm | Between membranes ≥ | 1.0 | |

Between membrane and aluminum plate ≥ | 1.5 | ||

Shank watertight | Pass | ||

Immersed in oil, pieces ≤ | 2 | ||

Holding Power/ min ≥ | 15 | ||

Thermal ageing | Elongation at the maximum tensile force, % | 40 | |

Flexibility at low temperature,( degree centigrade ) | -28 | ||

No cracking | |||

Sheering properties between membrane and aluminum plate, N/mm | 1.5 | ||

Dimension stability, % ≤ | 1.0 | ||

Self-adhesive bitumen re-peel strength, N/mm ≥ | 1.5 | ||

Surface Preparation

Surfaces should be dry, clean, smooth and free from any dusts, oil or loose particles. Cracks and uneven places need to be filled by polymer mortar.

Priming

Before membrane laying, substrate treating agent need to be brushed evenly and completely cover all laying places.

Membrane laying

After substrate treating agent drying, lay SAM-930A material according to application designs.

Sealing, fixing and constraining on vertical surfaces

On vertical surfaces, fix with metal battens and seal with sealants for membranes.

FAQ

1. Is sample available before place orders?

A: Yes, sample is ok.

2. How long is the dispatch period?

A: It will be around 20-30 days.

- Q: Can a waterproofing membrane be used in bridge decks or roadways?

- Yes, a waterproofing membrane can be used in bridge decks or roadways to enhance durability, prevent water damage, and extend the lifespan of the structure.

- Q: Are waterproofing membranes resistant to chlorine exposure?

- Waterproofing membranes can vary in their resistance to chlorine exposure. Some membranes are specifically designed to be resistant to chlorine and are commonly used in applications where chlorine exposure is expected, such as pool decks or water treatment facilities. These membranes are typically made with materials like PVC or TPO that have inherent resistance to chlorine and can withstand prolonged exposure without significant degradation. However, it is important to note that not all waterproofing membranes are chlorine-resistant. Some membranes, particularly those made with materials like EPDM or bitumen, may not be as resistant to chlorine and may experience deterioration or damage when exposed to chlorine for extended periods. To ensure the longevity and effectiveness of a waterproofing membrane in a chlorine-rich environment, it is crucial to select a membrane that is specifically designed and tested for chlorine resistance. Consulting with a waterproofing professional or manufacturer can help determine the most suitable membrane for the specific chlorine exposure conditions.

- Q: Can a waterproofing membrane be used in parking garages?

- Yes, a waterproofing membrane can be used in parking garages. Parking garages are exposed to various weather conditions, including rain and snow, and are often subjected to heavy vehicular traffic, which can lead to moisture infiltration and damage to the structure. Therefore, it is crucial to install a reliable waterproofing system to protect the parking garage against water penetration and potential structural deterioration. A waterproofing membrane is an effective solution for parking garages as it acts as a barrier against water and moisture. It is typically made of materials such as modified bitumen, PVC, or EPDM, which are durable and resistant to water intrusion. The membrane is applied to the surface of the concrete structure, creating a protective layer that prevents water from seeping through. The waterproofing membrane not only safeguards the parking garage against water infiltration but also helps to extend the lifespan of the structure. By preventing moisture from penetrating the concrete, it reduces the risk of corrosion, reinforcing steel deterioration, and the formation of cracks. This ultimately helps to maintain the structural integrity of the parking garage and avoid expensive repairs or replacements in the future. Additionally, a waterproofing membrane can also provide added benefits such as resistance to chemicals, UV radiation, and abrasion. This makes it an ideal solution for parking garages that are exposed to harsh environmental conditions and heavy traffic. In summary, a waterproofing membrane is highly recommended for use in parking garages as it offers reliable protection against water infiltration, helps to maintain the structural integrity of the garage, and extends its lifespan.

- Q: Does a waterproofing membrane require any special considerations for installation in high-humidity areas?

- Yes, a waterproofing membrane does require special considerations for installation in high-humidity areas. High humidity can increase the moisture levels that the membrane is exposed to, potentially affecting its performance and durability. It is important to choose a membrane specifically designed for high-humidity environments and follow proper installation techniques to ensure effective moisture protection. Additionally, regular inspections and maintenance should be conducted to prevent any potential damage or deterioration caused by the high humidity.

- Q: Can a waterproofing membrane be used on tunnels with railway systems?

- Yes, a waterproofing membrane can be used on tunnels with railway systems. Waterproofing membranes are commonly used in tunnel construction to prevent water ingress and protect the tunnel structure from deterioration. These membranes can effectively seal the tunnel walls, ceilings, and floors, preventing water from seeping into the tunnel and potentially causing damage to the railway system or infrastructure. Waterproofing membranes are specifically designed to withstand the high-pressure conditions and constant vibrations associated with railway operations. They are typically made of durable materials such as PVC, HDPE, or modified bitumen, which provide excellent waterproofing properties and long-term durability. Furthermore, these membranes can be installed during the construction phase of the tunnel or retrofitted onto existing tunnels with minimal disruption to the railway operations. Overall, the use of waterproofing membranes is a proven and effective method to ensure the structural integrity and longevity of tunnels with railway systems.

- Q: Can a waterproofing membrane be used in swimming pools or water features?

- Yes, a waterproofing membrane can be used in swimming pools or water features. Waterproofing membranes are specifically designed to prevent water leakage and can effectively seal and protect the surfaces of pools and water features from water damage.

- Q: Does a waterproofing membrane require any curing time before it can be exposed to water?

- Before being exposed to water, a waterproofing membrane does require a curing time. This curing time is necessary for the membrane to fully bond and reach its maximum strength, durability, and waterproofing capabilities. The specific duration of the curing time may vary depending on the type of membrane and the instructions provided by the manufacturer. To ensure proper curing and effective protection against water intrusion, it is crucial to adhere to these instructions. Neglecting to allow sufficient curing time can compromise the membrane's effectiveness, potentially resulting in leaks or other related issues. Therefore, it is highly recommended to wait until the specified curing time has passed before exposing the waterproofing membrane to water.

- Q: Can a waterproofing membrane be used for a plaza deck waterproofing?

- Yes, a waterproofing membrane can be used for plaza deck waterproofing. Waterproofing membranes are specifically designed to provide protection against water intrusion, making them an ideal choice for plaza deck waterproofing applications. These membranes are durable, flexible, and can effectively prevent water damage to the underlying structure.

- Q: Are waterproofing membranes resistant to alkalis?

- Waterproofing membranes, in general, exhibit resistance to alkalis. Alkalis, substances with high pH levels like sodium hydroxide or potassium hydroxide, can be present in various construction materials including concrete. The main purpose of waterproofing membranes is to create a protective barrier against water and other potentially harmful substances. They are typically manufactured using materials such as modified bitumen, PVC, or EPDM, which possess excellent alkali resistance. This resistance ensures that the waterproofing membrane remains intact and efficient even when exposed to alkaline substances. When dealing with materials or environments containing high levels of alkalis, it is crucial to choose a waterproofing membrane specifically designed for alkali resistance.

- Q: Can a waterproofing membrane be used for tunnels or underground structures?

- Yes, a waterproofing membrane can be used for tunnels or underground structures. Waterproofing membranes are designed to prevent water infiltration and can be applied to the interior or exterior surfaces of tunnels or underground structures to protect them from water damage. These membranes create a barrier that prevents water from seeping into the structure, ensuring its longevity and structural integrity.

Send your message to us

Self Adhesive Modified Bituminous Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords