Best Quality Self-adhesive Waterproofing Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 M2 m²

- Supply Capability:

- Above 10000M2 Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Self-adhesive Waterproofing Membrane | Width | Length | Thickness | Weight | |

Styrene butadiene styrene(SBS) modified bituminous sheet materials (PE) | 1m | 10m | 2mm | 28kg/roll | |

| 1m | 10m | 3mm | 41kg/roll | |

| 1m | 8m | 4mm | 45kg/roll | |

Styrene butadiene styrene(SBS) modified bituminous sheet materials with mineral granules(M)

| 1m | 10m | 3mm | 45kg/roll | |

| 1m | 8m | 4mm | 47kg/roll | |

| 1m | 8m | 5mm | 57kg/roll | |

Styrene butadiene styrene(SBS) modified bituminous sheet materials with aluminum foil(Al) | 1m | 10m | 2mm | 29kg/roll | |

| 1m | 10m | 3mm | 42kg/roll | |

| 1m | 8m | 4mm | 46kg/roll | |

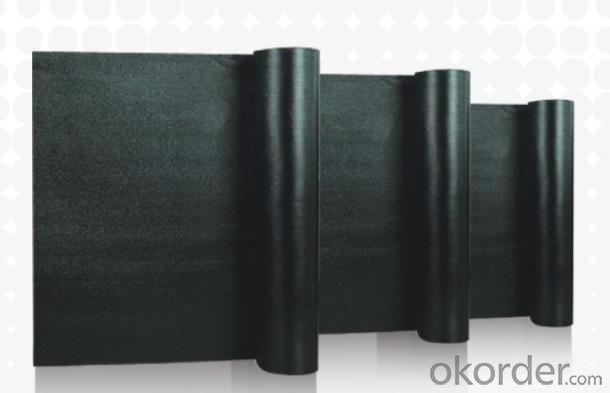

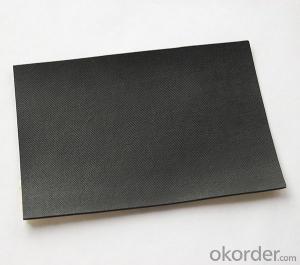

Pictures of of Self-adhesive Waterproof Membrane:

Characteristic of Self-adhesive Waterproof Membrane:

1)Self-adhesion without bonding agent,torching.

2)Good rubber elasticity,and elongation

3)Excellent adhension bond

4)Good self-coalescence

5)Safe application,no pullution

6)Excellent waterproof and high strength

7)Available for wet ground

8)Corrosion resistance and ageing-resistance

- Q: Can a waterproofing membrane be tiled over?

- Certainly, tiling over a waterproofing membrane is possible. Actually, it is strongly advised to incorporate a waterproofing membrane prior to tiling in areas susceptible to moisture, like bathrooms, showers, and outdoor patios. This membrane serves as a protective shield, preventing water from seeping through and safeguarding the underlying structure from harm. By placing tiles directly on the membrane, the durability and longevity of the tile installation are assured. It is crucial to adhere to the manufacturer's instructions and utilize suitable adhesives and grouts that harmonize with the waterproofing membrane to guarantee a triumphant and water-resistant tile installation.

- Q: Are waterproofing membranes resistant to chemical degradation?

- Yes, waterproofing membranes are generally resistant to chemical degradation. They are designed to withstand exposure to various chemicals, such as acids, alkalis, and solvents, without deteriorating or losing their effectiveness in preventing water penetration. However, the specific resistance to chemical degradation may vary depending on the type and quality of the membrane used.

- Q: Can a waterproofing membrane be used for wastewater facilities?

- Yes, a waterproofing membrane can be used for wastewater facilities. Waterproofing membranes are commonly used in wastewater facilities to prevent water leakage and seepage. They provide an effective barrier against water infiltration and protect the structure from water damage. Additionally, these membranes are resistant to chemicals and can withstand harsh environmental conditions often found in wastewater facilities.

- Q: How does a waterproofing membrane ensure a watertight seal around penetrations?

- By utilizing a waterproofing membrane, a watertight seal is established around penetrations, effectively obstructing water from infiltrating through these openings. Commonly composed of materials like rubber, PVC, or bitumen, which possess inherent water resistance properties, the membrane safeguards against water intrusion. Upon accurate application, the waterproofing membrane is encased around penetrations such as pipes, drains, or vents, forming a sealed layer that functions as a protective barricade. Typically, the membrane is affixed or mechanically fastened to the underlying surface, guaranteeing a secure and snug attachment. The membrane is deliberately engineered to exhibit flexibility, enabling it to adapt to the contours of the penetration. This adaptability guarantees the absence of any gaps or crevices through which water could potentially permeate. Furthermore, the membrane is often fortified with a layer of fabric or mesh, amplifying its durability and strength. In order to reinforce the watertight seal, specialized waterproofing accessories like collars, flanges, or boots are employed around the penetration. These accessories are specifically designed to snugly fit around the pipes or other protrusions, providing an additional layer of safeguarding against water infiltration. Ultimately, the implementation of a waterproofing membrane establishes a reliable barrier that thwarts water ingress through penetrations. It effectively seals off potential entry points, ensuring a watertight environment and preserving the underlying structure from water-related deterioration.

- Q: Are there any specific maintenance requirements for a waterproofing membrane?

- Yes, there are specific maintenance requirements for a waterproofing membrane. Regular inspections should be conducted to check for any signs of damage or deterioration, such as cracks or leaks. Any debris or standing water should be promptly removed to prevent potential damage. Additionally, it is important to follow the manufacturer's guidelines for cleaning and maintenance, which may include periodic cleaning with mild detergents and avoiding the use of harsh chemicals or abrasive cleaning tools.

- Q: Are waterproofing membranes suitable for high-traffic areas?

- Yes, waterproofing membranes are suitable for high-traffic areas. These membranes are designed to provide excellent durability and resistance against heavy foot traffic. They create a protective barrier that prevents water from seeping through and damaging the underlying structure. Additionally, waterproofing membranes can withstand the wear and tear caused by constant use, making them an ideal choice for areas with high foot traffic such as commercial spaces, parking garages, or outdoor walkways.

- Q: Can a waterproofing membrane be used on precast insulation surfaces?

- Yes, a waterproofing membrane can be used on precast insulation surfaces. The membrane acts as a protective barrier, preventing water penetration and ensuring the insulation remains dry and functional.

- Q: Are waterproofing membranes resistant to salt damage?

- Yes, waterproofing membranes are generally resistant to salt damage. Waterproofing membranes are designed to provide a barrier against moisture and water infiltration, and this includes protection against saltwater. Saltwater can be highly corrosive and can cause damage to various materials, but waterproofing membranes are typically made from materials that are resistant to the corrosive effects of salt. These membranes are often composed of materials such as reinforced PVC, modified bitumen, or EPDM rubber, which have proven to be durable and reliable in saltwater environments. Additionally, waterproofing membranes are commonly used in applications such as basements, swimming pools, and marine structures, where they are exposed to saltwater regularly. Therefore, it can be concluded that waterproofing membranes are generally resistant to salt damage and can provide effective protection against saltwater infiltration.

- Q: Can a waterproofing membrane be used on below-grade walls?

- Indeed, a waterproofing membrane is capable of being employed on walls located below ground level. In fact, it is highly advisable to utilize a waterproofing membrane on such walls so as to shield them against infiltration of water and potential harm caused by moisture. Walls situated below ground level are especially susceptible to water penetration due to their proximity to the ground and the possibility of hydrostatic pressure. A waterproofing membrane serves as a protective barrier, effectively preventing water from seeping into the walls and leading to issues such as mold, mildew, decay, and structural impairment. Moreover, it aids in maintaining the interior of the edifice in a dry condition, thereby averting potential problems related to moisture.

- Q: Can a waterproofing membrane be used for parking structures or garages?

- Yes, a waterproofing membrane can be used for parking structures or garages. Waterproofing membranes are commonly used in these types of structures to prevent water infiltration and protect the integrity of the building materials. They provide a barrier against moisture and help to extend the lifespan of the parking structure or garage by preventing water damage and corrosion.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2003 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | Europe; North America; Africa; Asia |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 50% - 100% |

| No.of Employees in Trade Department | 6- 10 people |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 100000 Square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | |

Send your message to us

Best Quality Self-adhesive Waterproofing Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 M2 m²

- Supply Capability:

- Above 10000M2 Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords