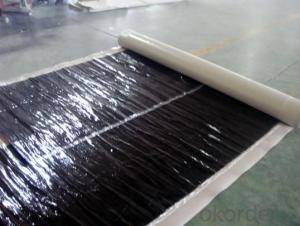

Self Adhesive Bitumen Waterproof Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

SBS(Styrene Butadiene Styrene) /APP (Atactic Polypropylene) modified bitumen membrane is made by saturating the base in bitumen, or thermoplastic elastomer (such as SBS, APP, APAO, APO), reinforced with polyester or fiberglass, finishing the upward face with polythene membrane, fine sands or mineral slates (or grains) or etc.

Specification

Thickness | 3mm, 4mm, 5mm |

Width | 1m |

length | 7.5m, 10m, 15m, or on demand |

Base | Polyester or Fiberglass felt |

Surface | PE film, Aluminum foil, Yellow sand, Shale gravel(Schist), colored sand |

Type | could self-adhesive |

Notice | SBS modified bitumen membrane is specially applied in the cold district, APP modified bitumen membrane is more suitable for hot district with high temperature. could be self-adhesive modified bitumen membrane |

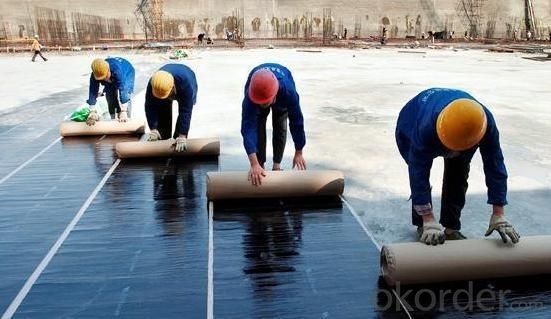

Applications Scope

Underground construction, garage roof, planted roof, roof garden

Metro, tunnel, pool, roof

Corrosive and deformed structure

Other warehouses, workshops with high requirement of waterproof

Water treatment engineering Roof works

Planted roof Underground construction

Traffic tunnel Urban traffic

FAQ

1. Is sample available before place orders?

A: Yes, sample is ok.

2. How long is the dispatch period?

A: It will be around 20-30 days.

- Q: Can a waterproofing membrane be used in mining or excavation projects?

- Yes, a waterproofing membrane can be used in mining or excavation projects. Waterproofing membranes are designed to prevent the ingress of water and other liquids, making them an ideal solution for areas that are prone to water intrusion, such as mines or excavations. These membranes are typically made from durable materials, such as rubber or bitumen, and are applied to the walls, floors, or roofs of these structures to create a watertight barrier. By using a waterproofing membrane, mining and excavation projects can minimize the risk of water damage, protect equipment and infrastructure, and ensure a safe working environment for workers.

- Q: Can a waterproofing membrane be used on precast chrome surfaces?

- Yes, a waterproofing membrane can be used on precast chrome surfaces. The membrane will provide a protective barrier against water penetration, ensuring the durability and longevity of the precast chrome surfaces.

- Q: Can a waterproofing membrane be used on precast galvanized surfaces?

- Precast galvanized surfaces can benefit from the use of a waterproofing membrane. This membrane serves as a safeguard against water infiltration and can be applied to various surfaces, including precast galvanized ones. By preventing water from seeping into the surface, the membrane safeguards the underlying structure from moisture damage. However, it is crucial to prepare the precast galvanized surface adequately before applying the membrane. This involves removing any loose or flaking galvanized coating to ensure proper adhesion of the membrane. Furthermore, it is recommended to consult the manufacturer or supplier of the waterproofing membrane to guarantee compatibility with galvanized surfaces and to follow their recommended application guidelines for optimal outcomes.

- Q: What is a waterproofing membrane?

- A waterproofing membrane is a thin layer or sheet made of materials like bitumen, rubber, or synthetic polymers that are applied to surfaces to prevent water penetration. It acts as a barrier, protecting structures such as roofs, basements, or foundations from water damage and leaks.

- Q: Do you know how many square meters of waterproofing membrane to send a set of tests?

- Elastomer Asphalt Waterproofing Sheets: Take a roll out of the outer roll head 2500mm, the vertical cut 800mm full-width coil sample 2. 10000 square meters for a group, the lack of a group also.

- Q: What is the difference between construction non-vulcanized waterproofing membrane and vulcanized waterproofing membrane?

- The vulcanized waterproofing membrane is characterized in that it consists of a vulcanized butyl rubber, a softening agent, a hard acid and a filler, wherein the parts by weight are butyl rubber: softening agent: hard acid: filler = 1 : 0.003-0.015: 0.006-0.036: 0.32-0.73, wherein the softening agent uses a mechanical oil, which can also be made into a high-strength waterproofing membrane by sandwiching a layer of the web between the two layers of the waterproofing membrane.

- Q: Can a waterproofing membrane be used for a tunnel lining?

- Yes, a waterproofing membrane can be used for a tunnel lining. A waterproofing membrane is a barrier that is designed to prevent water infiltration and protect the structure from moisture damage. It can be applied to the inner surface of a tunnel to effectively seal and waterproof the lining. This helps to prevent water ingress, which can lead to corrosion, deterioration, and structural issues over time. Additionally, a waterproofing membrane can also serve as a protective layer against other potential issues such as chemical attacks, groundwater pressure, and freeze-thaw cycles. It is important to select a waterproofing membrane that is specifically designed for tunnel applications to ensure it can withstand the unique conditions and requirements of tunnels, such as high water pressure and potential movement. Regular inspections and maintenance are also crucial to ensure the long-term effectiveness of the waterproofing membrane in a tunnel lining.

- Q: Can a waterproofing membrane be used on precast brick surfaces?

- Precast brick surfaces are vulnerable to water penetration, which can lead to structural damage and the growth of mold or mildew. To prevent this, a waterproofing membrane can be utilized. The membrane, typically composed of rubberized asphalt, modified bitumen, or polyurethane, is a flexible and durable material. It is applied to the surface using a brush or roller, forming a seamless layer that effectively blocks water infiltration into the bricks. Moreover, apart from its water-resistant properties, the waterproofing membrane also enhances the thermal insulation and longevity of the precast brick surfaces. However, it is crucial to ensure that the precast bricks are thoroughly cleaned, dried, and properly prepared prior to the application of the membrane for optimal adhesion and efficacy.

- Q: Are waterproofing membranes resistant to hydrostatic pressure?

- Waterproofing membranes have been specifically developed to resist hydrostatic pressure, which is the pressure exerted by still water. When a building is exposed to ground water, such as in basements or foundations, hydrostatic pressure becomes a significant concern as it can lead to water seeping through walls and floors. To prevent water from penetrating the building structure, waterproofing membranes are engineered to withstand and resist the pressure exerted by water. These membranes are typically made from materials like bitumen, rubberized asphalt, or synthetic polymers, all of which possess excellent water resistance properties. Moreover, the purpose of waterproofing membranes is to create an uninterrupted barrier against water, effectively preventing any potential leaks or seepage. They are applied in multiple layers, ensuring a sturdy and long-lasting barrier that can withstand the high pressure of water. It is crucial to note that the effectiveness of the waterproofing membrane in resisting hydrostatic pressure may vary depending on its type and quality. Hence, it is essential to choose a high-quality membrane and ensure proper installation to maximize its ability to resist hydrostatic pressure.

- Q: Are there any specific safety precautions to consider when installing a waterproofing membrane?

- Yes, there are several safety precautions to consider when installing a waterproofing membrane. Firstly, it is important to wear proper personal protective equipment (PPE) such as gloves, goggles, and a respirator to protect against potential chemical exposure and inhalation of fumes. Additionally, ensure adequate ventilation in the work area to prevent the buildup of fumes. It is also crucial to follow the manufacturer's instructions and guidelines for installation to minimize the risk of accidents or improper application. Lastly, be cautious of potential hazards such as slippery surfaces, sharp edges, or working at heights, and take necessary precautions to prevent falls or injuries.

Send your message to us

Self Adhesive Bitumen Waterproof Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords