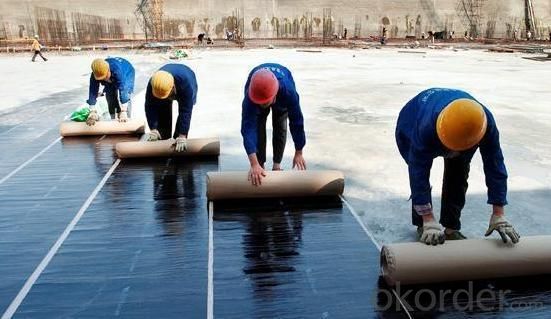

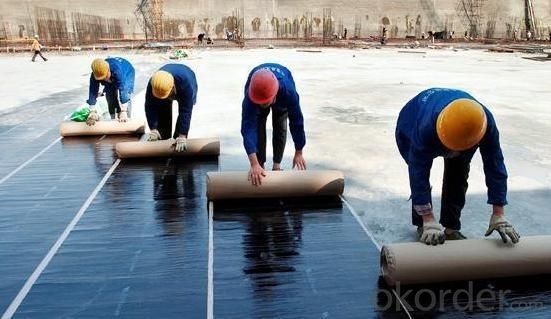

Self Adhesive Bitumen Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

SBS(Styrene Butadiene Styrene) /APP (Atactic Polypropylene) modified bitumen membrane is made by saturating the base in bitumen, or thermoplastic elastomer (such as SBS, APP, APAO, APO), reinforced with polyester or fiberglass, finishing the upward face with polythene membrane, fine sands or mineral slates (or grains) or etc.

Specification

Thickness | 3mm, 4mm, 5mm |

Width | 1m |

length | 7.5m, 10m, 15m, or on demand |

Base | Polyester or Fiberglass felt |

Surface | PE film, Aluminum foil, Yellow sand, Shale gravel(Schist), colored sand |

Type | could self-adhesive |

Notice | SBS modified bitumen membrane is specially applied in the cold district, APP modified bitumen membrane is more suitable for hot district with high temperature. could be self-adhesive modified bitumen membrane |

Applications

1). Roof and underground in industrial and civil buildings;

2). Bridge, subway, tunnel, swimming pool, etc.

3). Waste landfill, sewage plant, irrigation system, etc.

FAQ

1. Is sample available before place orders?

A: Yes, sample is ok.

2. How long is the dispatch period?

A: It will be around 20-30 days.

- Q: Is a waterproofing membrane suitable for use in areas with high groundwater levels?

- A waterproofing membrane works well in areas where the groundwater levels are high. Its purpose is to stop water from getting in, making it an effective barrier against groundwater. These membranes are usually made from materials like bitumen, PVC, or EPDM, which are extremely resistant to water and can handle a lot of pressure from below. They are built to create a tight seal, keeping water out of buildings or underground areas. Because of this, a waterproofing membrane is the perfect choice for places with high groundwater levels. It can successfully guard against water infiltration and the potential harm it could cause to structures or infrastructure.

- Q: Can a waterproofing membrane be used in conjunction with roofing materials?

- Yes, a waterproofing membrane can be used in conjunction with roofing materials. In fact, it is commonly used to provide an additional layer of protection against water infiltration and to enhance the overall waterproofing capabilities of the roof.

- Q: Are waterproofing membranes resistant to chemical degradation?

- Waterproofing membranes are typically resistant to chemical degradation, providing a barrier against water and other liquids. These membranes are specifically designed with materials that have excellent chemical resistance to withstand exposure to various chemicals, including acids, alkalis, and solvents, without significant degradation or damage. This chemical resistance ensures the long-term durability and effectiveness of the waterproofing system, making it suitable for applications such as basements, roofs, and underground structures. However, it should be noted that the specific chemical resistance may vary depending on the type of waterproofing membrane and the specific chemicals it is exposed to. Therefore, careful selection of the appropriate membrane based on the intended application and the specific chemical environment is crucial. Additionally, proper installation and maintenance are essential to ensure the continued chemical resistance and performance of the waterproofing membrane.

- Q: Can a waterproofing membrane be used on brass surfaces?

- To safeguard surfaces from water infiltration and harm, one usually employs a waterproofing membrane. Despite brass surfaces not being particularly susceptible to water damage, an additional safeguarding layer can still be applied in the form of a waterproofing membrane. This can aid in the prevention of moisture accumulation on the brass surface, ultimately averting tarnishing or corrosion. Nonetheless, it is crucial to acknowledge that brass surfaces are often sought after for their innate patina and aesthetic allure. The application of a waterproofing membrane may alter the brass's appearance, potentially resulting in a glossy or artificial finish. Thus, it is prudent to thoroughly ponder the desired outcome prior to opting for the utilization of a waterproofing membrane on brass surfaces.

- Q: Are waterproofing membranes resistant to chlorine exposure?

- Waterproofing membranes can vary in their resistance to chlorine exposure. Some membranes are specifically designed to be resistant to chlorine and are commonly used in applications where chlorine exposure is expected, such as pool decks or water treatment facilities. These membranes are typically made with materials like PVC or TPO that have inherent resistance to chlorine and can withstand prolonged exposure without significant degradation. However, it is important to note that not all waterproofing membranes are chlorine-resistant. Some membranes, particularly those made with materials like EPDM or bitumen, may not be as resistant to chlorine and may experience deterioration or damage when exposed to chlorine for extended periods. To ensure the longevity and effectiveness of a waterproofing membrane in a chlorine-rich environment, it is crucial to select a membrane that is specifically designed and tested for chlorine resistance. Consulting with a waterproofing professional or manufacturer can help determine the most suitable membrane for the specific chlorine exposure conditions.

- Q: Can waterproofing membranes be used in cold climates?

- Yes, waterproofing membranes can be used in cold climates. In fact, they are specifically designed to provide protection against moisture and water infiltration in various weather conditions, including cold temperatures. These membranes are typically made from durable, flexible materials that can withstand freezing temperatures without cracking or deteriorating. Additionally, some waterproofing membranes come with added features like thermal insulation, which helps to prevent heat loss and maintain a comfortable indoor environment in cold climates. Overall, waterproofing membranes are an effective solution for ensuring the integrity and longevity of structures in cold weather conditions.

- Q: How does a waterproofing membrane handle settlement or movement of the substrate?

- A waterproofing membrane is designed to accommodate settlement or movement of the substrate by possessing flexibility and elasticity. It can stretch or contract to a certain extent without losing its integrity or allowing water penetration. This ability allows the membrane to adapt to any changes in the substrate, ensuring long-term waterproofing performance.

- Q: What is the cost of installing a waterproofing membrane?

- The cost of installing a waterproofing membrane can vary depending on several factors such as the size of the area to be waterproofed, the type of membrane used, and the complexity of the installation. On average, the cost can range from $3 to $10 per square foot. However, it is recommended to obtain quotes from professional contractors to get an accurate estimate for your specific needs.

- Q: Are waterproofing membranes resistant to thermal expansion?

- Yes, waterproofing membranes are typically resistant to thermal expansion. They are designed to withstand temperature changes without undergoing significant dimensional changes, ensuring their effectiveness in preventing water penetration and maintaining their integrity.

- Q: Is a waterproofing membrane suitable for below-grade applications?

- Yes, a waterproofing membrane is suitable for below-grade applications.

Send your message to us

Self Adhesive Bitumen Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords