Self-adhesive Modified Bitumen Waterproof Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 60000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

Self Adhesive Bitumen Waterproof Membrane

Introduction:

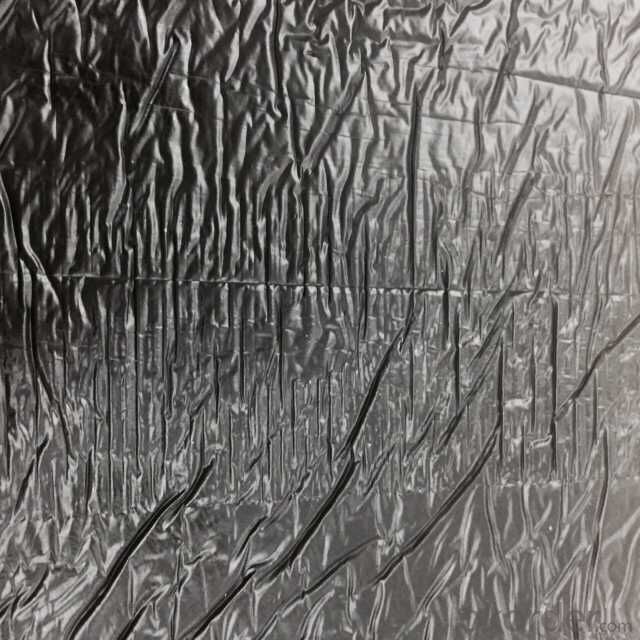

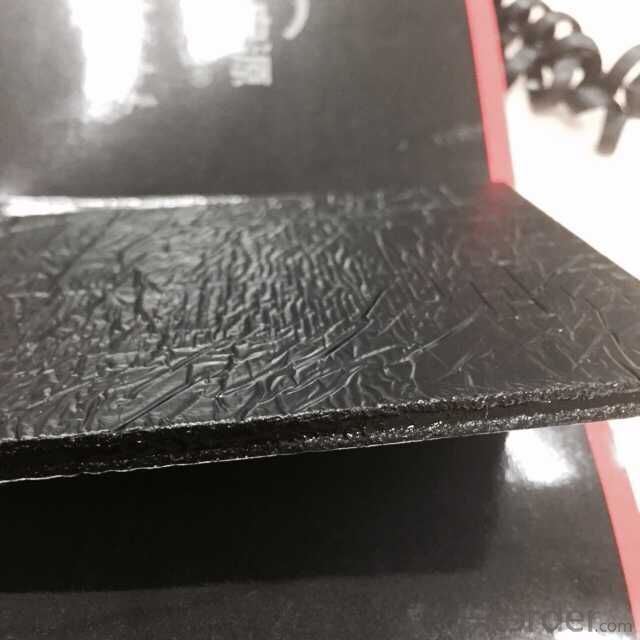

SBS(Styrene Butadiene Styrene) /APP (Atactic Polypropylene) modified bitumen membrane is made by saturating the base in bitumen, or thermoplastic elastomer (such as SBS, APP, APAO, APO), reinforced with polyester or fiberglass, finishing the upward face with polythene membrane, fine sands or mineral slates (or grains) or etc.

Specification:

Thickness | 3mm, 4mm, 5mm |

Width | 1m |

length | 7.5m, 10m, 15m, or on demand |

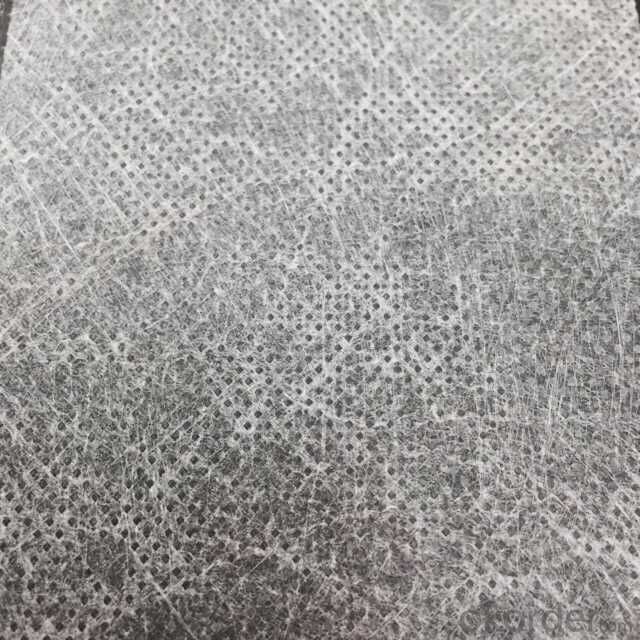

Base | Polyester or Fiberglass felt |

Surface | PE film, Aluminum foil, Yellow sand, Shale gravel(Schist), colored sand |

Type | could self-adhesive |

Notice | SBS modified bitumen membrane is specially applied in the cold district, APP modified bitumen membrane is more suitable for hot district with high temperature. could be self-adhesive modified bitumen membrane |

Applications:

-Roof and underground in industrial and civil buildings;

-Bridge, subway, tunnel, swimming pool, etc.

-Waste landfill, sewage plant, irrigation system, etc.

-Self-adhesive Modified Bitumen Waterproof Membrane

-Easy applying and economic on the cost saving

Advantage:

-Non-solidified, excellent elastic deformation,thus have good noise reducing;

-Easy applying and economic on the cost saving.

-Good performance on waterproof and economic sound damping.

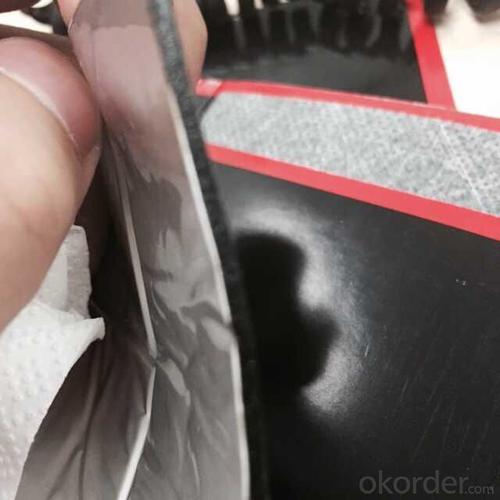

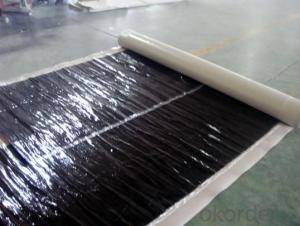

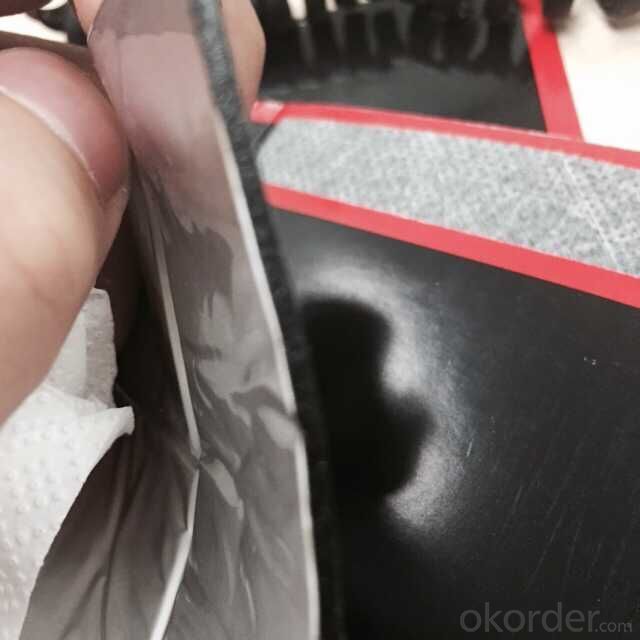

Picture:

Storage:

Shelf life is 12 months. Store in a cool and dry place with original packing.

Breathable Waterproof Roof Underlay membrane (PP-PP,S-PP,S-S)

Permeable membrane is polymer modified asphalt based, with surface of high strength polypropylene fiber. Back side coated with self adhesive glue or antiskid sand. Made by special process. With excellent waterproof performance and breathable properties.\

Description | Specification | Width | Length | Thickness | |

Roof underlay | 500g/m2PP—PP | 1000mm | 30m | 0.8mm | |

600g/m2S—PP | 1000mm | 25m | 1.0mm | ||

1500g/m2S—S | 1000mm | 20m | 1.3mm | ||

Roof underlay with adhesive band | 500g/m2PP—PP | 1000mm | 30m | 0.8mm | |

600g/m2S—PP | 1000mm | 25m | 1.0mm | ||

1500g/m2S—S | 1000mm | 20m | 1.3mm | ||

It is used as the underlayment of cement tile, painted pottery watts and asphalt shingle. Also suitable for all kinds of architectural roofing, walls, underground waterproof and damp proof project.

Features:

It has good waterproofing and ageing-resistance function,not flowing at highest temperature and no crack at lowest temperature;

Easy application,no pollution,and long service life etc.

Usage:

It is widely used for industry and civil building --- the waterproof and dampproof of the roofs,basements,toilets etc;and the waterproofing of bridges,parking area,tunnels,reserviors etc.

It is specially suitable to the building waterproofing in cold area and to the buildings of changeable constructions.

Requirements for surroundings

-The base should be dry and clean. Do not work in the rainy or snowy day.

-Do not work under heavy wind(above 5 grade)

-Unsuitable for construction below 0°C

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used in areas with extreme weather conditions, such as hurricanes or snowstorms?

- Yes, a waterproofing membrane can be used in areas with extreme weather conditions, such as hurricanes or snowstorms. Waterproofing membranes are designed to provide a protective barrier against water infiltration and can effectively withstand various weather conditions. They are made from materials that are resistant to moisture and can be installed in different areas like roofs, basements, or foundations. In regions prone to hurricanes, waterproofing membranes can help prevent water damage by creating a barrier that keeps water out even during heavy rainfall or storm surges. These membranes are often reinforced and have high tensile strength to withstand the strong winds and pressure associated with hurricanes. Similarly, in areas with heavy snowstorms, waterproofing membranes can help prevent water intrusion caused by melting snow or ice dams. They are designed to be flexible and resistant to extreme temperatures, ensuring that they maintain their integrity and prevent leaks even in freezing conditions. However, it is important to choose the right type of waterproofing membrane suitable for the specific weather conditions in the area. Different membranes have varying levels of resistance to extreme weather, so it is advisable to consult with a professional to determine the most appropriate membrane for the specific climate and weather patterns. Additionally, proper installation and regular maintenance are crucial to ensure the longevity and effectiveness of the waterproofing system in extreme weather conditions.

- Q: Are waterproofing membranes resistant to seawater?

- Yes, waterproofing membranes are resistant to seawater. These membranes are designed to provide a barrier against water and are specifically engineered to withstand the harsh conditions of seawater. They are made from materials that are highly resistant to saltwater corrosion and are tested to ensure their effectiveness in preventing water penetration, including the corrosive effects of seawater. This makes waterproofing membranes an ideal choice for applications where seawater exposure is a concern, such as in marine structures, coastal buildings, and swimming pools.

- Q: Can a waterproofing membrane be used in conjunction with roofing materials?

- Yes, a waterproofing membrane can be used in conjunction with roofing materials. In fact, it is commonly used to provide an additional layer of protection against water infiltration and to enhance the overall waterproofing capabilities of the roof.

- Q: Can a waterproofing membrane be installed underneath tile or other flooring materials?

- Certainly, tile or other flooring materials can have a waterproofing membrane installed underneath them. It is strongly advised to utilize a waterproofing membrane in wet areas like bathrooms, kitchens, or laundry rooms as a preventive measure against water damage and mold growth. The membrane functions as a shield separating the subfloor and the flooring material, effectively preventing any water or moisture from infiltrating and causing harm. Additionally, it offers an extra level of safeguarding against potential leaks or spills that might happen over time. By installing a waterproofing membrane, you can guarantee the durability, longevity, and absence of any water-related complications in your flooring.

- Q: Can a waterproofing membrane be used for a stadium roof?

- Yes, a waterproofing membrane can be used for a stadium roof. Waterproofing membranes are commonly used in construction projects, including roofs, to prevent water infiltration and protect the underlying structure from water damage. The membrane acts as a barrier against moisture and is designed to withstand the harsh outdoor elements, such as rain, snow, and UV radiation. By applying a waterproofing membrane to a stadium roof, it can help ensure that the roof remains watertight and prevents leaks, which is crucial for maintaining the integrity of the stadium and protecting spectators, equipment, and facilities inside. Additionally, waterproofing membranes are available in various types and materials, allowing for customization to meet the specific requirements and design of the stadium roof.

- Q: Can a waterproofing membrane be applied to existing structures?

- Yes, a waterproofing membrane can be applied to existing structures. The membrane acts as a protective barrier, preventing water from penetrating the structure and causing damage. It can be applied to various surfaces such as roofs, basements, and foundations, providing an effective solution for waterproofing existing buildings.

- Q: Can a waterproofing membrane be used on glass block surfaces?

- No, a waterproofing membrane cannot be used on glass block surfaces as they are already inherently waterproof.

- Q: Are waterproofing membranes breathable?

- Yes, waterproofing membranes can be breathable. Breathability refers to the ability of a material to allow air or water vapor to pass through it while still preventing liquid water from penetrating. Many modern waterproofing membranes are designed to be breathable, allowing moisture vapor to escape from within while still keeping out liquid water. This is especially important in applications such as waterproof clothing, outdoor gear, or building materials where moisture control is necessary to ensure comfort and prevent the growth of mold or mildew. Breathable waterproofing membranes typically use advanced technologies such as microporous membranes or coatings that allow water vapor molecules to pass through while blocking larger liquid water molecules.

- Q: Can a waterproofing membrane be used for military facilities?

- Yes, a waterproofing membrane can be used for military facilities. Waterproofing membranes are commonly used to protect structures from water infiltration and damage, which is crucial in military facilities to ensure the integrity and longevity of the infrastructure. Additionally, waterproofing membranes can also provide additional benefits such as protection against chemical and environmental hazards, making them suitable for military applications.

- Q: Can a waterproofing membrane be used in conjunction with green building practices?

- Certainly, a waterproofing membrane can be utilized alongside green building practices. In actuality, integrating a waterproofing membrane into the construction of a green building can greatly enhance its overall sustainability and efficiency. One of the fundamental principles of green building practices is to maximize energy efficiency and decrease the environmental impact of a structure. By installing a waterproofing membrane, the building's outer covering can be shielded from moisture intrusion, thereby preventing water damage and potential mold growth. This, in turn, aids in preserving the structural integrity of the building, reducing the necessity for costly repairs and replacements, which can consume resources and generate waste. Moreover, a waterproofing membrane can contribute to improved indoor air quality. By preventing water infiltration, it assists in creating a dry and healthy living or working environment, minimizing the risk of respiratory problems and other health issues associated with dampness. Furthermore, a waterproofing membrane can enhance the energy efficiency of a building. By preventing water from seeping into the walls or foundation, it lessens the potential for heat loss through moisture evaporation, thus reducing the energy required for heating and cooling. This can lead to decreased energy consumption and lower carbon emissions, aligning with the objectives of green building practices. However, it is crucial to select a waterproofing membrane that is environmentally friendly and compliant with green building standards. Seek out membranes that are crafted from recycled or sustainable materials and possess low VOC (volatile organic compound) content. Additionally, consider opting for a membrane that is designed for longevity and durability, as this can further minimize the environmental impact by reducing the need for replacement over time. In conclusion, a waterproofing membrane can be an invaluable addition to any green building endeavor. It serves to safeguard the building envelope, enhance indoor air quality, and improve energy efficiency. By choosing an environmentally friendly membrane, the overall sustainability of the building can be further enhanced.

Send your message to us

Self-adhesive Modified Bitumen Waterproof Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 60000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords