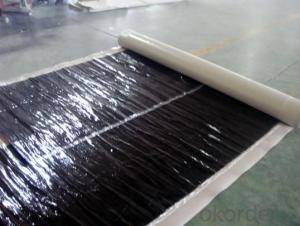

Self Adhesive Polymer Modified Bitumen Waterproof Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Wide self-adhesive pre PU polyester tyre water-proof coiled material (hereinafter referred to as pre Pu py) is to pitch based polyester tyre water-proof coiled material as the main material (add functional additives), both sides are coated with a self-adhesive layer and attached strippable coating silicon film as insulating material made of self-adhesive water-proof coiled material.

Wide self-adhesive macromolecular pre Pu waterproofing materials (hereinafter referred to as pre shop class P) with ethylene vinyl acetate (EVA), high density polyethylene (HDPE) homogeneous sheet material as the main body, covered with the self-adhesive layer, then covered with a silicon coated isolation membrane made of high polymer self-adhesive waterproofing membrane. According to the engineering needs, it can be in the polymer layer on the composite soil fabric, strengthen the strength of the membrane.

Wide wet PU polyester tyre water-proof coiled material is to pitch based polyester tyre water-proof coiled material as the main material (add functional additives), single or double coated adhesive layer and attached peelable coated silicon membrane as barrier materials made of wet laid waterproofing membrane.

Specification

Thickness | 3mm, 4mm, 5mm |

Width | 1m |

length | 7.5m, 10m, 15m, or on demand |

Base | Polyester or Fiberglass felt |

Surface | PE film, Aluminum foil, Yellow sand, Shale gravel(Schist), colored sand |

Type | could self-adhesive |

Notice | SBS modified bitumen membrane is specially applied in the cold district, APP modified bitumen membrane is more suitable for hot district with high temperature. could be self-adhesive modified bitumen membrane |

Advantages

Excellent waterproofness;

Unique creep properties and self-healing capability which can recover by itself;

Strong adhesion which can targeted the leakage in localized areas;

Tight joints, good extensibility;

Good stability and corrosion resistance, lasting effect.

FAQ

1. Is sample available before place orders?

A: Yes, sample is ok.

2. How long is the dispatch period?

A: It will be around 20-30 days.

- Q: Can a waterproofing membrane be used in conjunction with a drainage system?

- Yes, a waterproofing membrane can be used in conjunction with a drainage system. In fact, it is often recommended to have both systems working together to provide comprehensive protection against water damage. The waterproofing membrane acts as a barrier, preventing water from penetrating the structural elements. The drainage system, on the other hand, helps to collect and redirect any water that may accumulate, ensuring it is safely directed away from the building. By utilizing both systems, the risk of water infiltration and potential damage is greatly reduced.

- Q: Can a waterproofing membrane be used on concrete walls?

- Concrete walls can benefit from the use of a waterproofing membrane. These membranes are specifically designed to prevent water from penetrating the surface and can be applied to various surfaces, including concrete walls. Common materials used for these membranes include modified bitumen, rubberized asphalt, and synthetic polymers, all of which are highly resistant to water and moisture. By applying a waterproofing membrane to concrete walls, one can effectively prevent water seepage, dampness, and potential damage caused by water infiltration. The membrane acts as a protective barrier, stopping water from permeating through the concrete and reaching the interior spaces. Additionally, it helps maintain the structural integrity of the concrete by reducing the risks of cracks, efflorescence, and other forms of moisture-related deterioration. There are several types of waterproofing membranes available in the market, such as sheet membranes, liquid membranes, and cementitious coatings. The choice of the membrane depends on factors such as the specific application, the degree of water exposure, and the condition of the concrete wall. It is essential to select a membrane that is compatible with the concrete and provides long-lasting waterproofing protection. Before applying the membrane, it is crucial to properly prepare the concrete surface. This involves tasks such as cleaning, repairing any cracks or imperfections, and ensuring that the surface is dry and free from contaminants. The membrane is then installed according to the manufacturer's instructions, which usually involves adhering it to the concrete or applying a liquid membrane with a brush or roller. To sum up, a waterproofing membrane is a valuable solution for protecting concrete walls from water infiltration. By choosing the right type of membrane and following proper installation procedures, one can effectively preserve the durability and longevity of the concrete while safeguarding the interior spaces from potential water damage.

- Q: Can a waterproofing membrane be used in tunnels?

- Indeed, tunnels can indeed employ a waterproofing membrane. These membranes are frequently utilized in tunnels to thwart water infiltration and safeguard the structure from water-related harm. Generally composed of materials like bitumen, PVC, or polyurethane, these membranes possess impermeability to water as a core characteristic. When properly applied, a waterproofing membrane can act as a formidable barrier against water infiltration, thereby preserving the tunnel's integrity and avoiding expensive structural impairment. Furthermore, apart from their water-resistant properties, waterproofing membranes also provide defense against other substances like chemicals and gases, rendering them a versatile remedy for both tunnel construction and upkeep.

- Q: Can waterproofing membranes be used on concrete surfaces?

- Yes, waterproofing membranes can be used on concrete surfaces. Waterproofing membranes are designed to create a barrier against water penetration, and they are commonly used on concrete surfaces to protect them from water damage. These membranes are typically made of materials such as rubber, PVC, or bitumen, and they are applied to the concrete surface in a liquid or sheet form. Once applied, the membrane forms a continuous and durable waterproof layer that prevents water from seeping into the concrete. This is particularly beneficial in areas that are prone to water exposure, such as basements, bathrooms, or exterior concrete structures. Waterproofing membranes can effectively extend the lifespan of concrete surfaces by preventing water-related issues such as cracking, spalling, or mold growth.

- Q: Are waterproofing membranes suitable for historical buildings?

- Yes, waterproofing membranes can be suitable for historical buildings. These membranes provide an effective solution for preventing water penetration and damage to the structure, helping to preserve the integrity and longevity of the building. However, it is essential to consider the specific requirements and characteristics of the historical building and select an appropriate membrane that is compatible with its materials and architectural features. Additionally, any waterproofing work should be done with sensitivity and care to ensure it does not compromise the historical value or aesthetics of the building.

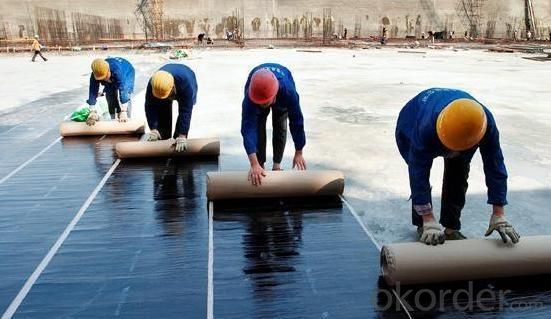

- Q: Are waterproofing membranes easy to install?

- Waterproofing membranes are generally easy to put in place. They can be found in various forms, such as sheets, rolls, or liquid coatings, which allows them to adapt to different surfaces and uses. Typically, the process involves cleaning and preparing the surface, applying the membrane, and ensuring a proper seal. While some technical knowledge and tools may be necessary, manufacturers often provide detailed instructions and guidelines for installation, making it easier for professionals and DIY enthusiasts alike. Furthermore, advancements in technology have resulted in the creation of self-adhesive membranes, which make the installation process even simpler. All in all, with proper preparation and following the correct installation procedures, waterproofing membranes can be installed relatively effortlessly.

- Q: Is a waterproofing membrane resistant to punctures or tears?

- Yes, a waterproofing membrane is designed to be resistant to punctures or tears. It is typically made from durable materials such as PVC, TPO, or EPDM, which are known for their strength and resistance to damage. These membranes undergo rigorous testing to ensure their ability to withstand various environmental conditions and potential sources of punctures or tears, such as sharp objects or heavy foot traffic. Additionally, some waterproofing membranes come with reinforcement layers or added protection to further enhance their puncture and tear resistance. However, it is important to note that while waterproofing membranes are highly resilient, they are not completely impervious to damage. Proper installation, regular maintenance, and avoiding unnecessary stress or impact on the membrane can help maximize its longevity and performance.

- Q: Are waterproofing membranes suitable for residential applications?

- Yes, waterproofing membranes are suitable for residential applications. They can effectively prevent water intrusion and protect homes from moisture damage, making them an ideal solution for basements, foundations, roofs, and other areas prone to water leakage.

- Q: Can a waterproofing membrane withstand heavy rain or water pressure?

- Yes, a waterproofing membrane is designed to withstand heavy rain and high water pressure. It is specifically engineered to create a barrier that prevents water from penetrating through, ensuring the protection and integrity of the underlying structure.

- Q: Can a waterproofing membrane be used for green roofs?

- Yes, a waterproofing membrane can indeed be used for green roofs. Waterproofing membranes are commonly used as a crucial layer in green roof construction to prevent water leakage and protect the underlying structure. It provides an effective barrier against water infiltration, ensuring the green roof system remains watertight and preserving the integrity of the building.

Send your message to us

Self Adhesive Polymer Modified Bitumen Waterproof Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords