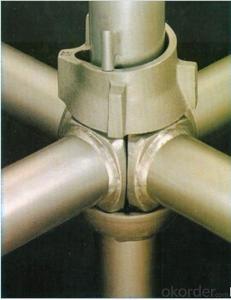

Scaffolding Cover Formwork Scaffolding Clamp Price New Design

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plastic Formwork Concrete Formwork Platform Outrigger for Scaffolding High Quality

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks. And workers love this new formworks much more.

The advantages of plastic formworks:

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

Modular formworks composed by different size of panels,the main item is 120×1500px panel,which is used for the large area of walls and slabs. There are also small size of panels like 10×1500px,20×1500pxcm,25×1500px,inner corner 20×20×1500px and outer corner 10×5×1500px.Due to the variety of panel size, the system can form almost all size walls 120×1500px panel of multiply by 125px. The material of modular formwork is PC-ABS mixed with special glass fibers which enable panels to hold high pressures.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

- Q: Are there any restrictions on the tolerance levels that can be achieved with steel frame formwork?

- Yes, there are restrictions on the tolerance levels that can be achieved with steel frame formwork. The accuracy of the formwork assembly, the quality of the steel used, and the precision of the construction techniques employed all play a role in determining the achievable tolerance levels. Additionally, factors such as the size and complexity of the structure being built also impact the level of tolerance that can be achieved.

- Q: ANSYS steel frame structure modeling, commonly used in size, density, Poisson's ratio is much better? Help。

- Such as the large cross-section of channel steel, I-beam, density 7.85x10^3/m^3

- Q: What are the common safety precautions for using steel frame formwork systems in high-rise construction?

- When using steel frame formwork systems in high-rise construction, there are several common safety precautions that should be followed to ensure the safety of workers and the success of the project. These precautions include: 1. Adequate training: All workers involved in the assembly, disassembly, and use of steel frame formwork systems should receive proper training on their safe handling and operation. This includes understanding the specific procedures and precautions related to the system being used. 2. Inspection and maintenance: Regular inspection and maintenance of the steel frame formwork systems are crucial to identify any defects or damage that could compromise safety. All components should be checked for signs of wear, deformation, or corrosion, and any issues should be addressed promptly. 3. Proper installation: It is essential to follow the manufacturer's instructions for the correct installation of the steel frame formwork system. This includes ensuring that all components are securely connected and that the system is stable and rigid. Any deviation from the installation guidelines can lead to structural instability and increase the risk of accidents. 4. Secure anchoring: Steel frame formwork systems should be properly anchored to the building structure to prevent movement or collapse during concrete pouring or other construction activities. Adequate bracing and tie-backs should be used to ensure stability and prevent any potential hazards. 5. Load capacity: It is crucial to be aware of the maximum load capacity of the steel frame formwork system and ensure that it is not exceeded. Overloading can lead to structural failure and pose a significant safety risk to workers. 6. Fall protection: High-rise construction involves working at heights, so it is essential to provide adequate fall protection measures. This can include the use of guardrails, safety harnesses, and safety nets to prevent falls and protect workers from injuries. 7. Regular inspections during use: While the formwork system is in use, regular inspections should be conducted to ensure its stability and integrity. Any signs of damage or movement should be addressed immediately to prevent accidents. 8. Communication and coordination: Effective communication and coordination among all workers involved in the installation and use of the steel frame formwork system are paramount. Clear communication ensures that everyone understands their roles and responsibilities, minimizing the risk of accidents caused by miscommunication or confusion. By following these common safety precautions, the use of steel frame formwork systems in high-rise construction can be done with a reduced risk of accidents and injuries, ensuring the safety of the workers and the successful completion of the project.

- Q: What are the different types of accessories used in conjunction with steel frame formwork?

- There are several types of accessories that are commonly used in conjunction with steel frame formwork. These accessories play a crucial role in ensuring the stability and effectiveness of the formwork system. 1. Wedge bolts: These are used to connect the steel frames together. They provide a tight and secure fit, ensuring that the frames remain in place during the concrete pouring process. 2. Tie rods: These are used to hold the formwork panels together. They are inserted through holes in the formwork and tightened using nuts and washers. Tie rods help to maintain the structural integrity of the formwork system. 3. Adjustable props: These are used to support the formwork panels vertically. They can be adjusted to the desired height and provide stability to the formwork system. Adjustable props are especially useful when working on uneven surfaces or when different heights are required. 4. Formwork clamps: These are used to hold the formwork panels tightly together, preventing any movement during the concrete pouring process. Clamps are typically made of steel and can be easily attached and removed, making them a convenient accessory for formwork systems. 5. Formwork spacers: These are used to maintain the correct spacing between the formwork panels. They ensure that the concrete is poured evenly and that the desired thickness of the structure is achieved. 6. Formwork ties: These are used to secure the formwork system to existing structures or to other formwork systems. They provide additional stability and prevent any shifting or movement during the concrete pouring process. 7. Formwork corners: These are pre-fabricated steel components that are used to create corners in the formwork system. They ensure that the formwork panels are properly aligned and provide a clean finish to the edges of the structure. Overall, these accessories are essential for the successful implementation of steel frame formwork systems. They provide stability, strength, and ease of use, making the construction process more efficient and reliable.

- Q: How does steel frame formwork handle the placement of façade cladding and curtain walls within the concrete structure?

- Steel frame formwork provides a sturdy and reliable support system for the placement of façade cladding and curtain walls within the concrete structure. The steel frames are designed to withstand the weight and pressure of the cladding and curtain walls, ensuring their proper installation and alignment. This formwork system allows for precise positioning and anchoring of the cladding and curtain walls, resulting in a seamless integration with the concrete structure and enhancing the overall aesthetics and functionality of the building.

- Q: How does steel frame formwork prevent leakage or seepage of concrete?

- Steel frame formwork is designed to prevent leakage or seepage of concrete by providing a tight and secure enclosure for the poured concrete. The steel frame acts as a strong barrier that holds the concrete in place and prevents it from escaping or seeping out. One of the key features of steel frame formwork is its ability to provide a seamless and continuous surface. The steel panels are connected together using robust locking mechanisms, ensuring that there are no gaps or openings through which the concrete can escape. This tight and secure connection between the panels prevents any leakage or seepage of the concrete. Additionally, steel frame formwork is designed to withstand the pressure exerted by the wet concrete during the pouring and curing process. The steel panels are strong and rigid, ensuring that they can withstand the weight and pressure of the concrete without buckling or deforming. This structural integrity of the steel frame further prevents any leakage or seepage of the concrete. Furthermore, steel frame formwork is often coated with special sealants or coatings that enhance its impermeability. These coatings provide an additional layer of protection against any potential leaks or seepage. They form a waterproof barrier that prevents water or moisture from penetrating the concrete and causing any damage. Overall, steel frame formwork is an effective solution for preventing leakage or seepage of concrete. Its seamless and continuous surface, structural integrity, and additional protective coatings ensure that the concrete remains securely contained within the formwork, resulting in a high-quality and durable structure.

- Q: How does steel frame formwork affect the overall durability of a concrete structure in harsh environments?

- In harsh environments, the use of steel frame formwork can greatly improve the overall durability of a concrete structure. By utilizing steel as the formwork material, several advantages are gained that help mitigate the negative effects of challenging conditions. To begin with, steel is renowned for its exceptional strength and durability. It has the ability to withstand heavy loads and extreme weather conditions, rendering it highly resistant to damage. This strength enables the steel frame formwork to support the weight of the wet concrete during the pouring and curing process, ensuring proper alignment and preventing any deformation or collapse of the structure. Additionally, steel possesses corrosion resistance, which is of particular concern in harsh environments like coastal areas or places with high humidity. Serving as a protective barrier, the steel frame formwork shields the concrete from exposure to moisture, saltwater, chemicals, and other corrosive elements. This safeguards the concrete from deteriorating over time, guaranteeing its long-term durability. Moreover, steel frame formwork provides outstanding dimensional stability. It reduces the risk of warping, cracking, or other deformations that can arise due to temperature variations, moisture content, or shrinkage of the concrete. This stability contributes to the structural integrity of the concrete, ensuring that it maintains its strength and functionality over an extended period. Furthermore, steel formwork allows for precise and accurate construction. The design of the steel frames ensures a stable and rigid structure, guaranteeing that the concrete is poured and compacted evenly throughout the formwork. As a result, a more uniform and durable concrete structure is achieved, with fewer imperfections or weak points. Ultimately, the application of steel frame formwork significantly enhances the overall durability of a concrete structure in harsh environments. Its strength, corrosion resistance, dimensional stability, and precise construction capabilities all contribute to the long-term structural integrity and functionality of the concrete, making it a reliable choice for projects in challenging conditions.

- Q: Cross stitch mounting, with steel frame or wooden frame

- With the expansion tube, self tapping screws into the first, tapping screws do not fully drill into the back of the exposed 0.5cm,

- Q: Can steel frame formwork be used for both horizontal and vertical concrete elements?

- Yes, steel frame formwork can be used for both horizontal and vertical concrete elements. It is a versatile and robust system that can be easily adjusted and reused for various construction projects.

- Q: Can steel frame formwork be used for sports stadiums?

- Sports stadiums can indeed be constructed using steel frame formwork. This construction technique is widely employed in the building industry and is particularly suitable for large-scale projects like sports stadiums. Steel frame formwork provides a robust and long-lasting framework for pouring concrete, enabling the construction of intricate and unique shapes in an efficient manner. By incorporating steel frame formwork into sports stadium construction, the building's structural integrity and stability are ensured, while also allowing for flexibility in meeting diverse design requirements. Moreover, steel frame formwork can be tailored to specific needs, making it appropriate for constructing stands, seating areas, and other essential features in sports stadiums. In summary, steel frame formwork is a dependable and effective construction method that can be successfully utilized for the development of sports stadiums.

Send your message to us

Scaffolding Cover Formwork Scaffolding Clamp Price New Design

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches