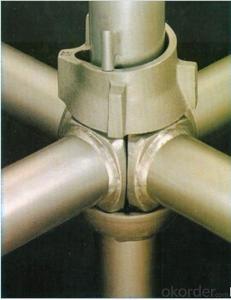

Scaffolding Sleeve Coupler Formwork Prop Jack Scaffolding New Design

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Scaffolding Sleeve Coupler Formwork Prop Jack Scaffolding New Design

Concrete Slab Formwork Scaffolding System Formwork Buy Scaffolding For Wholesales

Plastic Formwork Concrete Formwork Parts Of A Tubular Scaffolding Scaffolding Importers Low Price

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks. And workers love this new formworks much more.

The advantages of plastic formworks:

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

Scaffolding Sleeve Coupler Formwork Prop Jack Scaffolding New Design

Scaffolding Sleeve Coupler Formwork Prop Jack Scaffolding New Design

Scaffolding Sleeve Coupler Formwork Prop Jack Scaffolding New Design

FAQ Scaffolding Sleeve Coupler Formwork Prop Jack Scaffolding New Design

Concrete Slab Formwork Scaffolding System Formwork Buy Scaffolding For Wholesales

We have organized several common questions for our clients, may help you sincerely:

1)How is the Packaging Details?

In bags or as the requirement ofcustomers.

2)How long can we receive the product after purchase?

Lead time is about 30days after getting the signed PI and deposit.

- Q: What is the role of steel frame formwork in achieving a smooth concrete finish?

- Achieving a smooth concrete finish relies heavily on the crucial role of steel frame formwork. This type of formwork acts as a temporary mold or structure that securely holds the concrete in place as it cures and hardens. It plays a vital role in providing support and stability to the wet concrete, preventing any unwanted deformations or cracks during the curing process. One of the main advantages of utilizing steel frame formwork lies in its ability to deliver precise and accurate shapes to the concrete. The rigid and robust design of the steel frames ensures that the concrete maintains its desired dimensions and form. This becomes particularly significant when constructing structures with intricate details or complex designs. Moreover, steel frame formwork actively contributes to achieving a smooth concrete finish by minimizing any imperfections on the surface. The inflexible structure of the steel frames effectively prevents any movement or shifting of the concrete, resulting in a consistent and even surface. This becomes especially important when the concrete surface needs to exhibit visual appeal or when a smooth finish is required for functional purposes, such as flooring or walls. Furthermore, steel frame formwork offers the benefit of easy removal and reuse. After the concrete has fully cured and hardened, the formwork can be dismantled and removed, leaving behind a clean and finished concrete surface. The steel frames can then be cleaned and utilized again for future projects, reducing construction costs and minimizing waste. In conclusion, the indispensability of steel frame formwork in achieving a smooth concrete finish cannot be overstated. It provides the necessary support and stability to ensure the concrete maintains its desired shape and dimensions, while simultaneously minimizing surface imperfections. By employing steel frame formwork, construction projects can achieve high-quality concrete finishes that are both visually appealing and functionally effective.

- Q: What are the common quality control measures for steel frame formwork systems?

- There are several common quality control measures for steel frame formwork systems in the construction industry. These measures are implemented to ensure the integrity, strength, and safety of the formwork system during the concrete pouring process. Some of the common quality control measures include: 1. Material Inspection: The quality control process starts with a thorough inspection of the steel frame formwork system's materials. This includes checking the quality and specifications of the steel used for the frame, beams, and other components. Additionally, the inspection also focuses on the welding quality, surface finish, and overall structural strength of the steel components. 2. Dimensional Accuracy: It is crucial to ensure that the steel frame formwork system is manufactured with precise dimensions and tolerances. This involves verifying the accuracy of measurements, angles, and alignments of the formwork system components. Any discrepancies can lead to misalignment and compromise the integrity of the structure. 3. Load Testing: Load testing is performed to evaluate the load-bearing capacity and overall stability of the steel frame formwork system. This involves subjecting the formwork system to simulated loads that it will experience during the actual construction process. The system is carefully monitored to ensure it can withstand the expected loads without failure or deformation. 4. Safety Inspections: Safety is a critical aspect of quality control in steel frame formwork systems. Regular inspections are conducted to ensure that all safety features, such as handrails, guardrails, and access points, are properly installed and functioning correctly. Additionally, the inspection also verifies that the formwork system complies with industry safety standards and regulations. 5. Documentation and Record Keeping: Proper documentation and record keeping are essential for quality control in steel frame formwork systems. This includes maintaining records of material certifications, inspection reports, load testing results, and safety compliance documents. These records provide a comprehensive history of the formwork system's quality and help ensure traceability and accountability. 6. Inspection of Formwork Joints: The joints between different formwork components, such as beams and frames, need to be inspected for proper alignment and integrity. This involves checking for any gaps, misalignments, or loose connections that could compromise the stability and strength of the formwork system. By implementing these quality control measures, construction companies can ensure that steel frame formwork systems are manufactured and installed to the highest standards. This helps minimize the risk of structural failures, enhances worker safety, and ensures the successful completion of construction projects.

- Q: Can steel frame formwork be used in projects with tight construction schedules?

- Yes, steel frame formwork can be used in projects with tight construction schedules. Steel frame formwork offers several advantages that make it suitable for projects with tight timelines. Firstly, steel frame formwork is known for its high strength and durability. This means that it can withstand the pressure and stress of fast-paced construction activities without compromising its structural integrity. The use of steel frame formwork ensures that the formwork system remains intact and can be reused multiple times, reducing the time required for dismantling and reassembling. Additionally, steel frame formwork is highly adjustable and customizable, allowing for quick and efficient adaptation to different project requirements. This flexibility enables construction teams to work swiftly and make rapid adjustments to the formwork system as the project progresses. Moreover, steel frame formwork offers excellent dimensional stability, ensuring accurate and precise construction. This is crucial in projects with tight schedules as it reduces the need for rework and ensures that construction progresses smoothly and efficiently. Lastly, steel frame formwork is lightweight compared to traditional timber formwork, making it easier and faster to install and dismantle. This can significantly speed up the construction process and meet tight project deadlines. In conclusion, steel frame formwork is a suitable choice for projects with tight construction schedules due to its strength, durability, adjustability, dimensional stability, and lightweight nature. By utilizing steel frame formwork, construction teams can effectively save time, enhance productivity, and meet project deadlines without compromising on quality.

- Q: Can steel frame formwork be used for both temporary and permanent column construction?

- Steel frame formwork is capable of being utilized for the construction of both temporary and permanent columns. This versatile and robust solution can be employed repeatedly, rendering it appropriate for temporary applications where the formwork must be dismantled after the concrete has solidified. Furthermore, steel frame formwork is also suitable for permanent column construction, offering a resilient and trustworthy structure that can withstand the test of time. The steel frame formwork system can be tailored to meet the specific needs of the project, ensuring the columns possess the correct dimensions and reinforcement. All in all, steel frame formwork is a flexible alternative that can be employed for both temporary and permanent column construction.

- Q: What are the key considerations for selecting the appropriate steel frame formwork supplier for international projects?

- When choosing a supplier for steel frame formwork for international projects, there are several important factors to take into account. Firstly, it is crucial to evaluate the supplier's experience and track record in working on international projects. This involves reviewing their past projects, especially those that are similar in size and scope to the current project. A supplier who has successfully completed international projects in the past will likely have the necessary expertise and knowledge of the specific requirements and challenges that may arise. Secondly, it is essential to consider the supplier's ability to meet international standards and regulations. Different countries have different building codes and regulations that must be followed, so it is important to ensure that the supplier has experience in complying with these standards. This will help to ensure that the steel frame formwork provided is of high quality and meets all safety requirements. Additionally, it is important to evaluate the supplier's ability to handle logistics and transportation for international projects. This includes assessing their ability to deliver the formwork to the project site on time, as well as their understanding of any customs and import/export requirements that may be involved. A supplier with a strong network and efficient logistical capabilities can help to minimize delays and ensure smooth operations throughout the project. Furthermore, it is crucial to consider the supplier's after-sales support and technical assistance. International projects may require troubleshooting and technical guidance, so it is important that the supplier offers reliable support and assistance throughout the project. This can include providing training for on-site personnel, responding promptly to inquiries, and having a dedicated team to address any issues that may arise. Lastly, the cost-effectiveness of the supplier's offerings should be considered. While quality and reliability are important, it is also necessary to ensure that the supplier's prices are competitive and within the project's budget. This can be achieved by requesting detailed quotations and comparing them with those of other suppliers in the market. In conclusion, selecting the right steel frame formwork supplier for international projects involves careful consideration of factors such as experience, compliance with international standards, logistical capabilities, after-sales support, and cost-effectiveness. By thoroughly evaluating these factors, project stakeholders can make an informed decision and choose a supplier that best meets the project's needs.

- Q: What are the requirements for the installation and the characteristics of the chimney sliding formwork

- Safety: to have enough strength, stiffness and stability, to ensure that the construction of no deformation, no damage, no collapse

- Q: Does steel frame formwork require any specific edge protection measures?

- Yes, steel frame formwork does require specific edge protection measures. These measures are necessary to ensure the safety of workers and prevent any potential accidents or falls from the edges of the formwork. Edge protection systems such as guardrails, toe boards, and safety nets should be installed to provide a safe working environment for construction personnel.

- Q: How does steel frame formwork contribute to the overall sustainability of a construction project?

- There are several ways in which the use of steel frame formwork contributes to the overall sustainability of a construction project. To begin with, steel is an extremely durable material that can withstand the demands of construction. This durability ensures that the formwork system will last a long time, reducing the need for frequent replacements. As a result, there is a decrease in waste generation and resource consumption. Furthermore, unlike traditional timber formwork that is often discarded after one use, steel frame formwork can be dismantled and reused multiple times. This significantly reduces material waste and minimizes the environmental impact of the construction process. Moreover, steel is a recyclable material. Once it reaches the end of its useful life as formwork, steel frames can be recycled and used to create new steel products. This helps to reduce the demand for new materials and conserve natural resources. In addition, steel frame formwork offers flexibility in design and construction. Its modular nature allows for easy customization and adjustment, minimizing the need for excessive material cutting and reducing construction waste. This adaptability also ensures efficient resource use and decreases the overall environmental footprint of the project. Furthermore, steel frame formwork enables faster construction compared to traditional formwork systems. This results in reduced energy consumption, lower carbon emissions, and a smaller environmental impact. In conclusion, the use of steel frame formwork promotes sustainability in construction projects by promoting durability, reusability, recyclability, flexibility, and efficiency. By incorporating steel frame formwork, construction projects can minimize waste, conserve resources, reduce carbon emissions, and create more sustainable built environments.

- Q: Are there any specific considerations for using steel frame formwork in corrosive environments?

- In corrosive environments, there are several specific factors to consider when using steel frame formwork. To begin with, it is crucial to select the appropriate type of steel for the formwork. Stainless steel, which contains high levels of chromium, is commonly utilized in corrosive environments due to its outstanding corrosion resistance properties. It is resistant to rust and can endure exposure to corrosive substances like saltwater or chemicals. In addition, it is necessary to adequately coat or protect the formwork to prevent corrosion. This can be achieved through methods such as galvanization or the application of protective coatings like epoxy or zinc-rich paint. These coatings create a barrier that prevents corrosive agents from reaching the steel surface and causing damage. Moreover, regular maintenance and inspection are vital to ensure the longevity of the steel formwork in a corrosive environment. This involves regularly cleaning to eliminate any accumulated corrosive substances and conducting periodic inspections to detect any signs of corrosion or damage. Any identified corrosion should be promptly addressed and repaired to prevent further deterioration. Lastly, it is essential to consider the design and construction of the formwork in order to minimize the potential for corrosion. This may entail incorporating features such as proper drainage to prevent the accumulation of corrosive substances, avoiding the use of dissimilar metals that can cause galvanic corrosion, and ensuring adequate ventilation to reduce moisture levels. Overall, the utilization of steel frame formwork in corrosive environments necessitates careful material selection, protective coatings, regular maintenance, and appropriate design considerations to ensure the durability and longevity of the formwork.

- Q: Can steel frame formwork be used for the construction of transportation infrastructure?

- Yes, steel frame formwork can be used for the construction of transportation infrastructure. Steel frame formwork is a versatile and durable system that is commonly used in various construction projects, including transportation infrastructure such as bridges, tunnels, and highways. Steel frame formwork offers several advantages for the construction of transportation infrastructure. Firstly, its strength and rigidity allow it to withstand heavy loads and provide excellent support for the concrete during the construction process. This is especially important in transportation infrastructure projects where the structures need to be able to bear significant weight and withstand various environmental conditions. Additionally, steel frame formwork is highly customizable, allowing it to be easily adapted to different shapes and sizes required for transportation infrastructure. This flexibility ensures that the formwork can be tailored to specific project requirements, ensuring optimal results and efficient construction. Moreover, steel frame formwork is reusable, making it a cost-effective solution for transportation infrastructure projects. The ability to reuse the formwork not only reduces construction costs but also minimizes waste and environmental impact. Furthermore, steel frame formwork provides a smooth and high-quality finish to the concrete structures, which is crucial for transportation infrastructure where precision and durability are paramount. The formwork system allows for accurate placement and alignment of the concrete, ensuring the integrity and longevity of the infrastructure. In conclusion, steel frame formwork is a suitable choice for the construction of transportation infrastructure due to its strength, versatility, reusability, and ability to deliver high-quality results. Its usage can contribute to the successful and efficient completion of transportation projects, ensuring the durability and safety of the infrastructure.

Send your message to us

Scaffolding Sleeve Coupler Formwork Prop Jack Scaffolding New Design

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches