QES Scaffolding Formwork Scaffolding Wall Tie with Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

QES Scaffolding Formwork Scaffolding Wall Tie with Low Price

Scaffolding For High-Rise Buildings Formwork Scaffolding Truss High Quality

Frame Scaffolding Systems Formwork Bs Standard Scaffolding Tube With Low Price

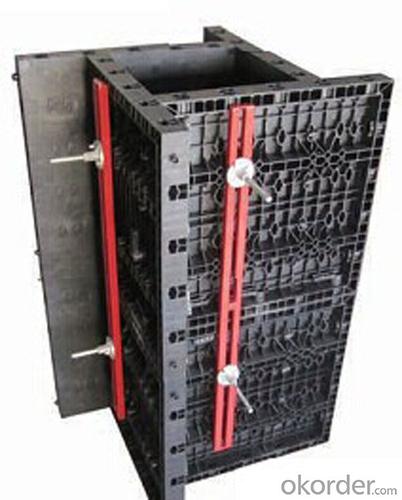

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks. And workers love this new formworks much more.

The advantages of plastic formworks:

QES Scaffolding Formwork Scaffolding Wall Tie with Low Price

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

Modular formworks composed by different size of panels,the main item is 120×1500px panel,which is used for the large area of walls and slabs. There are also small size of panels like 10×1500px,20×1500pxcm,25×1500px,inner corner 20×20×1500px and outer corner 10×5×1500px.Due to the variety of panel size, the system can form almost all size walls 120×1500px panel of multiply by 125px. The material of modular formwork is PC-ABS mixed with special glass fibers which enable panels to hold high pressures.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

5.Environment friendly

The system needs no cut and nail due to the variety size. Also it needs nearly no wood. The material can be recycled after broken, so it will not pollute the environment.

6.Consequent

Concrete does not stick to plastic formwork, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which build by modular formwork is smooth and without rework.

QES Scaffolding Formwork Scaffolding Wall Tie with Low Price

QES Scaffolding Formwork Scaffolding Wall Tie with Low Price

QES Scaffolding Formwork Scaffolding Wall Tie with Low Price

QES Scaffolding Formwork Scaffolding Wall Tie with Low Price

Advantage

* Good loading capacity

* Easy to assemble and dismantle

* Stable and durable thanks to its structual design & automatic welding quality

* Customized solution helps you work safe, save cost and convenient

* Excellent quality for formwork & scaffolding with wide choices

Packing

in bulk or in bundle, or as requested

Shipping

15-20 Days.

Normally small orders, it needs just 15-20 business days to the port. For goods with stock, it would be even shoter.

QES Scaffolding Formwork Scaffolding Wall Tie with Low Price

Other scaffolding & formwork products:

(1) Scaffolding System:

Including Ringlock Scaffolding System and accessories; Cuplock Scaffolding System and accessories; Kwikstage Scaffolding System and accessories; Haki Scaffolding System and accessories;

(2) Scaffolding Frame & Accessories:

Including Walk Through Frame Scaffolding; Ladder Frame Scaffolding; Accessories; we also can make scaffolding according to your samples or drawings.

(3) Scaffolding Couplers/Clamps:

We can produce all kinds of forged and pressed couplers, including British type couplers, American type couplers, German type couplers, Italian type couplers ,fence couplers, BRC coplers and so on. We also can produce according to your drawings or samples.

(4) Formwork System Scaffolding & Accessories:

Light Duty Shoring prop and Heavy Duty Shoring Prop; Wing nuts and Tie rods; RASTO clamp and so on.

FAQ QES Scaffolding Formwork Scaffolding Wall Tie with Low Price

Why Us?

We are one of the Top 500 in the world, largest construction materials supplier in China. Also we are a state-owned company and respond to every customer with large and also small orders.

We own professional manufacturers with powerful producing capacity.

Extensive and comprehensive quality control system

Excellent products with competitive prices.

Efficient services in pre and after sale.

Full energy with affluent experience team.

- Q: What are the different types of formwork anchors used with steel frame formwork systems?

- Steel frame formwork systems utilize various types of formwork anchors to provide stability and support during the concrete pouring process. Included in these anchors are loop ties, adjustable clamps, wedges, C-clamps, formwork brackets, formwork ties, and combination anchors. Loop ties serve as a popular choice for attaching formwork panels to the steel frame. They comprise a looped wire that is inserted through the formwork and securely fastened to the frame using tie rods or other fastening methods. To secure the formwork panels to the steel frame, adjustable clamps are employed. These clamps can be easily adjusted to accommodate different panel thicknesses, ensuring a tight and secure connection. Wedges are utilized to securely fasten formwork panels to the steel frame. These wedges are inserted into specially designed slots on the frame, providing a robust and steadfast connection. C-clamps, designed with a convenient C-shape, are utilized for attaching formwork panels to the steel frame. Due to their shape, these clamps effortlessly slide onto the frame, establishing a secure connection. Formwork brackets are employed to support the formwork panels and enhance stability. These brackets can be adjusted to the desired height and angle, and are attached to the steel frame. Formwork ties are used to connect multiple formwork panels together. These ties are inserted through the panels and securely fastened to the steel frame using tie rods or other fastening methods. Combination anchors offer versatility and can be used for various applications. These anchors integrate different elements, such as loops, clamps, and wedges, to establish a secure connection between the formwork panels and the steel frame. These examples represent only a fraction of the diverse formwork anchors employed in steel frame formwork systems. The selection of an appropriate anchor relies on factors such as formwork design, load requirements, and specific project needs. It is crucial to choose the correct anchor to ensure the stability and safety of the formwork during the concrete pouring process.

- Q: Does steel frame formwork require any specific training for installation?

- Installation of steel frame formwork requires specific training. This complex system involves precise assembling and installation processes, making it crucial for installers to possess the necessary knowledge and skills to ensure safety and effectiveness. Training for steel frame formwork installation typically includes learning how to interpret technical drawings and specifications, as well as familiarizing oneself with the various components and materials used in the formwork system. Installers are taught proper handling, lifting, and positioning techniques for steel frames, as well as the correct methods for connecting and securing formwork panels and accessories. Moreover, training encompasses important safety procedures and measures that must be followed during installation, such as wearing personal protective equipment and ensuring the stability and structural integrity of the formwork. Understanding the load capacities and limitations of the steel frame formwork system is also crucial to avoid potential accidents or structural failures. In conclusion, specific training for steel frame formwork installation is indispensable. It guarantees correct installation, compliance with standards and specifications, and provides a safe and stable support for concrete construction projects.

- Q: How does steel frame formwork accommodate for different concrete finishing requirements?

- Steel frame formwork is a versatile and adaptable solution that can easily accommodate different concrete finishing requirements. One of the main advantages of steel frame formwork is its ability to be adjusted and modified, allowing for precise control over the shape, size, and texture of the final concrete structure. To accommodate for different concrete finishing requirements, steel frame formwork offers various customization options. Firstly, the formwork can be easily adjusted to create different shapes and sizes of concrete structures. This flexibility is particularly useful when dealing with complex architectural designs or non-standard shapes. Additionally, steel frame formwork allows for the integration of different types of form liners, which can be used to create specific textures or patterns on the concrete surface. By using different materials or textures for the form liners, a wide range of finishes can be achieved, such as smooth, exposed aggregate, or textured surfaces. Furthermore, steel frame formwork can be combined with other techniques to enhance the concrete finishing. For example, the formwork can be used in conjunction with chemical retarders or surface retarders to create exposed aggregate finishes or to minimize surface imperfections. It can also be combined with the use of form release agents to facilitate the removal of the formwork and ensure a smooth surface finish. In summary, steel frame formwork accommodates different concrete finishing requirements by providing flexibility in shape and size, enabling the use of different form liners for various textures and patterns, and allowing for the integration of additional techniques to enhance the final concrete finish. Its adaptability and versatility make it a preferred choice for construction projects that require precise control over the concrete finishing.

- Q: How does steel frame formwork handle different types of concrete surface cleaning methods?

- Steel frame formwork is a versatile and durable system used in the construction industry to support and shape concrete structures. When it comes to cleaning different types of concrete surfaces, steel frame formwork can handle various methods effectively. One common method used to clean concrete surfaces is pressure washing. Steel frame formwork is designed to withstand high-pressure water jets, making it suitable for this cleaning technique. The sturdy steel frames can withstand the force of the water without getting damaged or deformed. Additionally, the steel surface is resistant to water and can prevent any corrosion or rusting during the cleaning process. Another method for cleaning concrete surfaces is chemical cleaning. This involves using specialized cleaning agents to remove stains, dirt, or other contaminants. Steel frame formwork is compatible with most cleaning chemicals, as steel is resistant to most corrosive substances. However, it is essential to ensure that the cleaning agents used do not cause any damage to the steel frames or compromise their structural integrity. In some cases, mechanical cleaning methods such as scrubbing or sandblasting may be required to remove stubborn stains or coatings on concrete surfaces. Steel frame formwork can handle these methods as well. The robust steel frames can withstand the mechanical force exerted during scrubbing or sandblasting without being damaged. However, it is crucial to use appropriate techniques and tools to prevent any scratches or dents on the steel surface. In summary, steel frame formwork can handle different types of concrete surface cleaning methods effectively. Whether it is pressure washing, chemical cleaning, or mechanical cleaning, the strong and durable steel frames can withstand the forces and chemicals involved without getting damaged. However, it is essential to use proper techniques and cleaning agents that do not compromise the integrity of the steel frames or lead to any corrosion.

- Q: What maintenance is required for steel frame formwork?

- Maintenance for steel frame formwork typically includes regular cleaning, inspection, and repair as needed. Here are some specific maintenance tasks for steel frame formwork: 1. Cleaning: It is important to clean the steel frame formwork after each use to remove any concrete residue or debris. This can be done using water, soap, and a brush or pressure washer. Regular cleaning helps prevent corrosion and ensures the longevity of the formwork. 2. Inspection: Regular inspections are necessary to identify any signs of damage or wear and tear. Inspect the frame for cracks, dents, bent or loose components, and damaged connections. Pay special attention to areas that are exposed to high stress or pressure during use. 3. Repair: If any damages or defects are found during the inspection, immediate repair is essential. Repair or replace any damaged components to maintain the structural integrity of the formwork. This may involve welding, grinding, or replacing parts as necessary. 4. Lubrication: Lubricating movable parts of the steel frame formwork, such as hinges, bolts, and sliding mechanisms, helps prevent friction and ensures smooth operation. Use appropriate lubricants recommended by the manufacturer to minimize wear and prolong the life of the formwork. 5. Storage: Proper storage is vital to prevent damage and corrosion. Store the steel frame formwork in a clean and dry area, away from direct sunlight, moisture, and harsh weather conditions. Use protective covers or coatings to shield the formwork from corrosion during storage. 6. Training: It is important to provide proper training to the personnel handling the steel frame formwork. Educate them about the correct usage, handling, and maintenance procedures to ensure optimal performance and safety. By following these maintenance practices, steel frame formwork can be kept in good condition, resulting in improved safety, efficiency, and durability during construction projects.

- Q: Can steel frame formwork be used in projects with limited construction site supervision or management?

- Yes, steel frame formwork can be used in projects with limited construction site supervision or management. Steel frame formwork is a durable and reliable system that provides stability and support for concrete structures. It is designed to be easy to assemble and disassemble, making it suitable for projects with limited supervision or management. Additionally, steel frame formwork offers flexibility and versatility, allowing for adjustments and modifications as needed during construction.

- Q: How long does steel frame formwork typically last?

- Steel frame formwork typically lasts for a long time, typically ranging anywhere from 10 to 20 years or more, depending on various factors such as the quality of the steel, the maintenance practices, and the frequency of use. With proper care and regular maintenance, steel frame formwork can withstand the pressures and stresses of construction projects for multiple years without significant deterioration. However, it is worth noting that the lifespan of steel frame formwork can be influenced by external factors such as exposure to harsh weather conditions, improper handling or storage, and excessive wear and tear. Therefore, it is essential to consider these factors and implement appropriate maintenance measures to ensure the longevity and efficiency of steel frame formwork.

- Q: Are there any specific considerations for using steel frame formwork in cold climates?

- Yes, using steel frame formwork in cold climates requires several specific considerations. 1. Material selection: It is crucial to choose steel specifically designed to withstand low temperatures in order to prevent brittleness and cracking. 2. Insulation: Insulating the steel formwork is essential to maintain a consistent temperature during the concrete curing process and prevent heat loss. This can be achieved by using materials like foam or thermal blankets around the formwork. 3. Condensation control: In cold climates with high humidity levels, measures must be implemented to control condensation on the steel formwork. This includes using vapor barriers or ensuring proper ventilation to prevent rusting and reduced structural integrity. 4. Heating: In extremely cold climates, additional heating may be necessary to ensure proper concrete curing. This can be done through electric or propane heaters or enclosing the formwork in heated enclosures. 5. Thermal expansion and contraction: Steel has a higher coefficient of thermal expansion than concrete, making it crucial to design the formwork system to accommodate temperature fluctuations in cold climates. Failure to do so can lead to structural damage or misalignment. 6. Surface protection: Steel formwork exposed to cold climates is more prone to corrosion due to moisture and de-icing salts. Applying anti-corrosion coatings or galvanization is necessary to ensure the longevity and durability of the formwork. Considering these factors enables the effective use of steel frame formwork in cold climates, ensuring successful construction of concrete structures even in challenging weather conditions.

- Q: What are the different types of support beams used with steel frame formwork?

- Construction projects commonly use several types of support beams in conjunction with steel frame formwork. These beams are crucial for providing stability and strength to the formwork system. Some of the support beams used with steel frame formwork include: 1. H-beams: These beams, shaped like the letter "H," are frequently used and have excellent load-bearing capacity due to their high-strength steel composition. 2. I-beams: Also known as universal beams, these beams have a cross-section shaped like the letter "I" and are ideal for bearing heavy loads. They are commonly employed in large construction projects that require high strength and stability. 3. Box beams: With a rectangular or square cross-section resembling a box, these beams possess a remarkable load-bearing capacity. They are typically utilized in projects where heavy loads need support. 4. Channel beams: Channel beams, or C-beams, have a cross-section shaped like the letter "C." They serve as secondary support beams in steel frame formwork, enhancing strength and stability. Channel beams are often used alongside other types of support beams. 5. Lattice beams: These lightweight and versatile support beams have a lattice-like structure. They are commonly employed in steel frame formwork to span long distances and offer a high level of flexibility. The selection of support beams for steel frame formwork depends on factors such as load requirements, project specifications, and budget constraints. Choosing the appropriate support beams is crucial to ensure the safety and stability of the formwork system throughout construction.

- Q: What are the advantages of steel frame structure

- Durability: light steel structure residential cold-formed thin-walled steel structure using all system components, steel using super anticorrosion high strength cold rolled galvanized sheet manufacturing, effectively avoid the influence of the steel in the construction and use of the process of corrosion, increase the service life of steel member. Structural life up to 100 years.

Send your message to us

QES Scaffolding Formwork Scaffolding Wall Tie with Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords