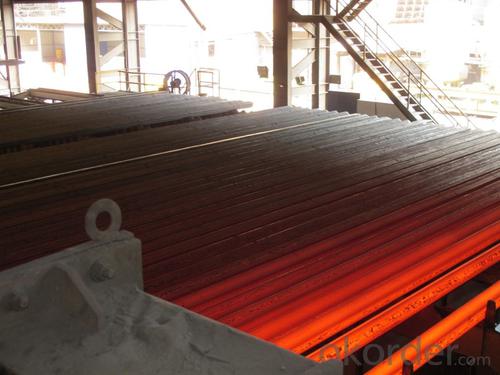

Q235/3SP 75MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Q235/3SP 75MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels consist of a steel substrate with a metallic zinc coating applied by means of a continuous hot dip galvanising process. Metallic zinc coatings are available in steel grades ranging from steel for bending and deep drawing applications, to structural steels and high yield strength steels.

A glossy surface finish obtained under specific skin-pass conditions (either non-skin-passed or skin- passed with smooth cylinders to obtain low roughness) can be provided if required at time of enquiry.

Advantage of Q235/3SP 75MM Blast Furnace Hot Rolled Steel Billet

Uncoated CR steel sheet With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Q235/3SP 75MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels can be used in a very wide range of applications for industrial markets, both indoors and outdoors. Some of the most common applications are:

Building: wide sections for roofing and cladding, doors, door frames, metallic ceilings, partitions, structural members etc

Domestic appliances: all appliances for this sector (both white and brown goods) are manufactured with hot dip galvanised steels

Miscellaneous: electrical cabinets, aeraulic components, air conditioners, road signs etc

Zinc hot dip galvanised steel is suitable for contact with foodstuffs under certain conditions, as specified in European directive 89/109/EEC and French standard NF A 36-712-1. Please contact us for further information on this subject.

Specifications of Q235/3SP 75MM Blast Furnace Hot Rolled Steel Billet

Quality | Q/BQB 440-2003 | JIS G3312-1994 JIS G3321 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | DC51D | SGCC SGLCC | DX51D+Z DX51D+AZ | CS Type A/B/C |

Forming Steel | St01,St02,St03 | SGCD1 SGLCD1 | FS Type A, Type B | |

Drawing | DC52D /DC53D | - | DX52D+Z DX52D+AZ | DDS TYPE A/C |

Steel | DX53D+Z DX53D+AZ | |||

Structural | S280GD (StE28) | SGC400 SGLC400 | S280D+Z DX54D+AZ | SS275 |

Steel | S350GD (StE34) | SGC440 SGLC440 | S350D+Z S350D+AZ | SS340 Class1 |

FAQ of Q235/3SP 75MM Blast Furnace Hot Rolled Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How are steel billets used in the manufacturing of valves and fittings?

- Valves and fittings rely on steel billets, an essential raw material, for their production. These billets are solid steel forms, cast into specific shapes and sizes. The manufacturing process starts by heating the steel billets to a high temperature and passing them through rolling mills to achieve the desired form. This process refines the grain structure, enhancing the steel's strength, ductility, and overall quality. After shaping, the billets undergo further processing and machining to create various valve and fitting components, including bodies, bonnets, stems, and other essential parts. Precise machining ensures accurate dimensions and smooth surfaces, enabling proper assembly and functioning. Steel billets also provide crucial strength and durability to valves and fittings, as they are made from high-quality steel. This ensures that the final products can withstand the harsh operating conditions, pressure, and temperature variations they may encounter. Moreover, steel billets offer versatility in manufacturing, allowing the production of different types of valves and fittings, such as gate valves, ball valves, butterfly valves, and pipe fittings. This flexibility enables manufacturers to meet diverse industry requirements. In summary, steel billets serve as the primary raw material in the production of valves and fittings. Shaping, processing, and machining these billets result in high-quality components that offer strength, durability, and precision in the final products.

- Q: What are the safety measures involved in handling steel billets?

- Some safety measures involved in handling steel billets include wearing personal protective equipment such as gloves, safety glasses, and steel-toed boots to protect against potential injuries. Additionally, using proper lifting techniques and equipment like cranes or forklifts can help prevent strain or accidents. It is important to ensure that the work area is well-lit and free of clutter to minimize trips and falls. Regular maintenance and inspection of equipment is also crucial to prevent any malfunctions or hazards.

- Q: What are the different shapes available for steel billets?

- Steel billets are commonly manufactured in various shapes to meet the diverse needs of different industries. Some of the different shapes available for steel billets include: 1. Square Billets: These are billets with equal sides, forming a square shape. Square billets are widely used in the construction industry for manufacturing beams, columns, and other structural components. 2. Round Billets: These billets have a circular cross-section and are commonly used in the production of seamless pipes, tubes, and rods. Round billets are also utilized in the automotive and aerospace industries for manufacturing various components. 3. Rectangular Billets: These billets have unequal sides, forming a rectangular shape. Rectangular billets are often utilized in the construction industry for manufacturing frames, window profiles, and other structural elements. 4. Hexagonal Billets: Hexagonal billets have six equal sides, forming a hexagon shape. These billets are commonly used in the production of bolts, nuts, and other fasteners that require a hexagonal shape for proper fitting. 5. Octagonal Billets: Octagonal billets have eight equal sides, forming an octagon shape. These billets are often used in the manufacturing of special components and tools that require a unique shape for specific applications. 6. Slab Billets: Slab billets have a rectangular cross-section with a larger width compared to their height. Slab billets are primarily used for producing flat-rolled steel products such as sheets, plates, and coils. 7. Bloom Billets: Bloom billets have a square or rectangular cross-section with a larger size compared to regular billets. These billets are commonly used in the production of sections, bars, and rails. The choice of the steel billet shape depends on the specific requirements of the desired end product and the manufacturing process involved. The versatility of steel billets makes them suitable for a wide range of applications in various industries.

- Q: What is the role of steel billets in the manufacturing of agricultural machinery?

- Steel billets play a crucial role in the manufacturing process of agricultural machinery. These billets are essentially semi-finished steel products that are typically cast into a rectangular shape. They serve as the raw material for various components and parts of agricultural machinery. The use of steel billets provides several advantages in the manufacturing of agricultural machinery. Firstly, steel is known for its exceptional strength and durability, making it an ideal material for heavy-duty machinery that is subjected to harsh operating conditions. Steel billets, being the starting point of the manufacturing process, ensure that the final products possess the necessary strength and durability to withstand the demands of agricultural activities. Moreover, steel billets offer versatility in design and fabrication. Agricultural machinery requires a wide range of components with different shapes and sizes, and steel billets can be easily molded and machined to meet these requirements. This flexibility allows manufacturers to produce complex parts that are essential for the efficient operation of agricultural machinery. Additionally, steel billets provide consistent and reliable quality. The manufacturing process of steel billets involves strict quality control measures to ensure uniformity and adherence to industry standards. This consistency in quality translates into reliable performance and longevity of the agricultural machinery, reducing the need for frequent repairs or replacements. Furthermore, steel billets have excellent resistance to corrosion and wear, which is crucial for agricultural machinery exposed to various environmental elements. The use of steel billets ensures that the final products can withstand exposure to moisture, chemicals, and abrasive materials commonly encountered in agricultural settings. In summary, steel billets are integral to the manufacturing of agricultural machinery due to their strength, durability, versatility, consistent quality, and resistance to corrosion and wear. By using steel billets as the raw material, manufacturers can produce agricultural machinery that meets the demanding requirements of the agricultural industry, ensuring reliable and efficient performance in various farming applications.

- Q: What are the different types of cleaning equipment used for steel billets?

- There are several types of cleaning equipment used for steel billets, including shot blasting machines, acid pickling tanks, ultrasonic cleaning tanks, and high-pressure water jets. These equipment are utilized to remove scale, rust, and other impurities from the surface of the billets, ensuring they are clean and ready for further processing or manufacturing.

- Q: What are the potential applications of steel billets in the medical sector?

- The medical sector has a wide range of potential applications for steel billets. One key use is in the manufacturing of medical instruments and surgical tools. Steel's high strength and durability make it an ideal material for producing precise and reliable instruments. Scalpels, forceps, bone saws, and orthopedic implants are just a few examples of the various medical tools that can be made from steel billets and are essential for surgeries and procedures. Moreover, steel billets can be utilized in the production of medical equipment like hospital beds, wheelchairs, and stretchers. These products require a strong and robust material to ensure patient safety and comfort. Steel provides the necessary strength to support the weight of patients and withstand regular usage, making it an excellent choice for these applications. Additionally, steel billets can be used in the construction of medical facilities and infrastructure. Steel is renowned for its structural integrity, making it suitable for building hospitals, clinics, and research laboratories. Steel structures offer resistance against earthquakes, fires, and other natural disasters, ensuring the safety of both medical personnel and patients. Furthermore, steel billets can be employed in the manufacturing of medical storage systems and cabinets. These storage solutions are crucial for maintaining a sterile and organized environment, preventing cross-contamination, and ensuring the proper storage of medical supplies and equipment. To sum up, steel billets have extensive potential in the medical sector. Steel's strength, durability, and reliability make it an invaluable material for enhancing patient care and safety, whether it's through the production of surgical instruments, medical equipment, construction of medical facilities, or manufacturing of medical storage solutions.

- Q: How are steel billets cut and shaped into desired forms?

- Steel billets are cut and shaped into desired forms through a process called hot rolling. The billets are heated and then passed through a series of rollers, which apply pressure and shape the steel into various profiles such as bars, rods, or sheets. This process allows for precise control over the dimensions and specifications of the final product.

- Q: How are steel billets used in the production of railway parts?

- Steel billets are an important raw material used in the production of railway parts. These billets are essentially semi-finished steel products that are cast into a specific shape and size, typically in a square or rectangular form. They serve as the starting point for the manufacturing process of various railway components. One of the primary applications of steel billets in the production of railway parts is for the manufacturing of rails. The billets are heated and then passed through a series of rolling mills to shape them into the desired rail profile. This process, known as rolling, involves applying pressure to the billet, which gradually elongates and shapes it into the rail section. The resulting rails are then cut to the required length and undergo further processes such as heat treatment and finishing to enhance their strength and durability. Apart from rails, steel billets are also used in the production of other crucial railway components such as wheels, axles, and various structural parts. For example, billets can be forged or machined to form the wheel blanks, which are subsequently processed to create the final wheel shape. Similarly, billets can be used to manufacture axles by forging and machining them into the desired dimensions and specifications. Additionally, steel billets may be employed in the fabrication of various structural parts used in railway infrastructure, including bridges, tunnels, and platforms. These billets are processed through different manufacturing techniques such as casting, forging, or machining to produce the required components. In summary, steel billets play a vital role in the production of railway parts. From manufacturing rails to wheels, axles, and structural components, these billets serve as the starting material that undergoes various shaping, heat treatment, and finishing processes to create the final railway components that ensure safe and efficient transportation.

- Q: What are the different shapes and sizes of steel billets?

- Steel billets come in various shapes and sizes, including square, round, rectangular, and hexagonal. The sizes of steel billets can range from small dimensions, such as 100mm x 100mm, to larger dimensions, such as 400mm x 400mm. These different shapes and sizes of steel billets serve different purposes and can be used in various industries, including construction, manufacturing, and automotive.

- Q: What are the different types of steel billet rolling mills?

- There are several different types of steel billet rolling mills that are used in the steel industry. These mills are designed to roll billets, which are heated steel bars, into various shapes and sizes. Some of the most common types of steel billet rolling mills include: 1. Two-high rolling mills: These mills have two rolls that are positioned one above the other. The billet is passed between the rolls, which apply pressure and shape the steel into the desired form. 2. Three-high rolling mills: In these mills, there are three rolls, with the top and bottom rolls being smaller in diameter compared to the middle roll. The billet is passed through these rolls, and the middle roll applies the majority of the pressure to shape the steel. 3. Four-high rolling mills: These mills have two smaller rolls positioned above two larger rolls. The billet is passed through the smaller rolls first, which shape the steel, and then through the larger rolls to further refine its shape. 4. Cluster rolling mills: In these mills, multiple rolls are arranged in a cluster. The billet is passed through these rolls, which apply pressure from different angles and directions to shape the steel. 5. Tandem rolling mills: These mills consist of multiple stands of rolling mills arranged in a tandem configuration. Each stand of the mill performs a specific shaping operation on the billet, and the billet is passed through each stand in sequence until it achieves the desired shape. 6. Continuous rolling mills: These mills are designed for continuous operation and are used for high-volume production. The billet is continuously fed into the mill, and the rolls apply pressure to shape the steel as it passes through. Each type of steel billet rolling mill has its own advantages and is used for specific applications in the steel industry. The choice of mill depends on factors such as the desired shape and size of the final product, production volume, and the specific requirements of the steel being processed.

Send your message to us

Q235/3SP 75MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords