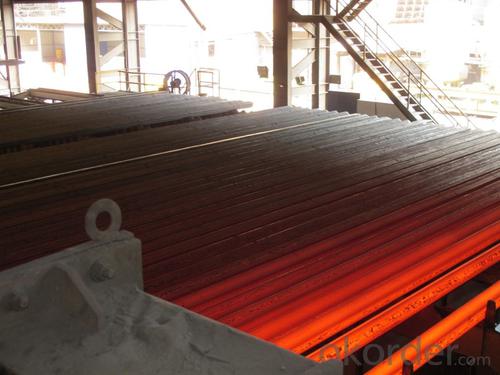

Q235/3SP 85MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Q235/3SP 85MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels consist of a steel substrate with a metallic zinc coating applied by means of a continuous hot dip galvanising process. Metallic zinc coatings are available in steel grades ranging from steel for bending and deep drawing applications, to structural steels and high yield strength steels.

A glossy surface finish obtained under specific skin-pass conditions (either non-skin-passed or skin- passed with smooth cylinders to obtain low roughness) can be provided if required at time of enquiry.

Advantage of Q235/3SP 85MM Blast Furnace Hot Rolled Steel Billet

Uncoated CR steel sheet With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Q235/3SP 85MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels can be used in a very wide range of applications for industrial markets, both indoors and outdoors. Some of the most common applications are:

Building: wide sections for roofing and cladding, doors, door frames, metallic ceilings, partitions, structural members etc

Domestic appliances: all appliances for this sector (both white and brown goods) are manufactured with hot dip galvanised steels

Miscellaneous: electrical cabinets, aeraulic components, air conditioners, road signs etc

Zinc hot dip galvanised steel is suitable for contact with foodstuffs under certain conditions, as specified in European directive 89/109/EEC and French standard NF A 36-712-1. Please contact us for further information on this subject.

Specifications of Q235/3SP 85MM Blast Furnace Hot Rolled Steel Billet

Quality | Q/BQB 440-2003 | JIS G3312-1994 JIS G3321 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | DC51D | SGCC SGLCC | DX51D+Z DX51D+AZ | CS Type A/B/C |

Forming Steel | St01,St02,St03 | SGCD1 SGLCD1 | FS Type A, Type B | |

Drawing | DC52D /DC53D | - | DX52D+Z DX52D+AZ | DDS TYPE A/C |

Steel | DX53D+Z DX53D+AZ | |||

Structural | S280GD (StE28) | SGC400 SGLC400 | S280D+Z DX54D+AZ | SS275 |

Steel | S350GD (StE34) | SGC440 SGLC440 | S350D+Z S350D+AZ | SS340 Class1 |

FAQ of Q235/3SP 85MM Blast Furnace Hot Rolled Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What is the average lifespan of a steel billet in the automotive industry?

- The average lifespan of a steel billet in the automotive industry can vary depending on several factors such as the specific application, type of steel used, and maintenance practices. However, on average, steel billets in the automotive industry can last for several years to decades, especially when properly cared for and maintained.

- Q: How are steel billets used in the manufacturing of structural steel?

- Steel billets are a crucial raw material in the manufacturing of structural steel. These billets, which are essentially semi-finished steel products, are typically produced through a process called continuous casting, where molten steel is solidified into a rectangular shape. Once the steel billets are formed, they are further processed in steel mills to create various structural steel products such as beams, columns, angles, and channels. The billets are heated and then passed through a series of rolling mills, where they undergo intense pressure and shaping to achieve the desired dimensions and profiles. During the rolling process, the steel billets are elongated and transformed into long, slender shapes. This is achieved by repeatedly passing the billets through a set of rollers, which gradually reduce their cross-sectional area. The rolling mills can be configured differently to produce different types of structural steel products, catering to specific construction requirements. After the rolling process, the structural steel products are further subjected to various finishing processes such as cooling, cutting, straightening, and surface treatment. These processes ensure that the final product meets the required specifications, including dimensional accuracy, surface quality, and mechanical properties. The use of steel billets in the manufacturing of structural steel offers several advantages. Firstly, the semi-finished nature of billets allows for flexibility in customization, enabling the production of steel products with different sizes, shapes, and profiles. Additionally, the continuous casting process used to produce billets ensures a more consistent and uniform material quality, reducing the risk of defects or inconsistencies in the final product. Overall, steel billets play a vital role in the manufacturing of structural steel by providing a reliable and versatile raw material. Their transformation through rolling and other processes allows for the production of high-quality, durable, and structurally sound steel products that are widely used in construction, infrastructure, and industrial applications.

- Q: How are steel billets shaped into other forms?

- Steel billets are shaped into other forms through a process called hot rolling. Hot rolling involves passing the steel billet through a series of heated rollers that compress and shape the billet into the desired form. First, the steel billet is heated to a high temperature in a furnace. This heat treatment makes the steel more malleable and easier to shape. Once the billet reaches the desired temperature, it is fed into a rolling mill. In the rolling mill, the billet is passed through a series of rollers that apply pressure and force to shape the steel. These rollers can have various shapes and sizes depending on the desired outcome. As the billet passes through the rollers, it is gradually shaped into the desired form, such as sheets, bars, or beams. The rolling process not only shapes the steel but also improves its mechanical properties. It refines the grain structure, enhances the strength and toughness, and removes any internal defects. This makes the steel more suitable for various applications, such as construction, automotive, and machinery. After the hot rolling process, the steel is often further processed through cold rolling, which involves passing it through cold rollers to refine its surface finish and dimensions. Additionally, other secondary operations like cutting, bending, and welding may be performed to further shape the steel into the desired end product. Overall, hot rolling is a crucial process in shaping steel billets into other forms. It allows for the production of a wide range of steel products, each with its specific shape, size, and mechanical properties, meeting the diverse needs of industries worldwide.

- Q: How long do steel billets last?

- The lifespan of steel billets can vary depending on various factors such as the quality of the steel, storage conditions, and usage. Generally, steel billets can last for decades if stored properly and used within their recommended lifespan.

- Q: How are steel billets used in the production of electrical appliances?

- Steel billets are used in the production of electrical appliances as a raw material that is shaped and formed into various components such as casings, frames, brackets, and other structural parts. These billets are melted, cast, and rolled into the desired shape and size, providing the necessary strength, stability, and durability required for electrical appliances.

- Q: What are the different methods of steel billet cutting and machining?

- Steel billets can be cut and machined using several different methods, each with its own advantages and applications. Some of the most commonly used methods include: 1. Sawing: To cut through a steel billet, a saw blade is employed. This method is relatively straightforward and cost-effective, making it suitable for cutting large quantities of billets into desired lengths. However, it may result in rough edges and necessitate additional finishing processes. 2. Flame cutting: Also known as oxy-fuel cutting, this method involves using a combination of fuel gas and oxygen to create a high-temperature flame that melts and cuts through the steel billet. It is effective for cutting thick billets and can achieve a high level of precision. Flame cutting can be carried out manually or using automated machines. 3. Plasma cutting: This method utilizes a plasma torch to generate a high-velocity jet of ionized gas that melts and cuts through the steel billet. It is particularly effective for cutting through thick materials and intricate shapes and curves. Plasma cutting provides high cutting speeds and excellent precision. 4. Waterjet cutting: In this method, a high-pressure jet of water mixed with abrasive particles is used to cut through the steel billet. Waterjet cutting is versatile and can handle various materials, including steel, without generating heat-affected zones or causing distortion. It is ideal for cutting complex shapes and thin materials. 5. Laser cutting: Laser cutting involves the use of a high-powered laser beam to melt and vaporize the steel billet along a predefined path. This method offers exceptional precision and enables intricate and complex cuts. Laser cutting is commonly used for thin to medium thickness billets and is suitable for both small-scale and industrial applications. In addition to these cutting methods, there are various machining processes that can be applied to steel billets, such as milling, turning, drilling, and grinding. These processes involve removing material from the billet to achieve desired shapes, dimensions, and surface finishes. The choice of machining method depends on factors such as the complexity of the part, required tolerances, and production volume. Overall, the different methods of steel billet cutting and machining provide a range of options for manufacturers to effectively shape and process steel billets according to their specific requirements.

- Q: Are steel billets prone to corrosion?

- Yes, steel billets are prone to corrosion. Steel is primarily made from iron, and iron is susceptible to rusting and oxidation when exposed to moisture and oxygen. Therefore, steel billets, which are the raw form of steel used for further processing, can corrode if not properly protected or maintained.

- Q: What are the properties of high-quality steel billets?

- High-quality steel billets are sought after for their desirable properties in various applications. Chiefly, these billets boast a high degree of purity, containing minimal impurities like sulfur, phosphorus, and other non-metallic elements. This purity contributes to the overall strength and performance of the steel. Another crucial property of high-quality steel billets is their uniform internal structure. This means that the grains within the billet are evenly distributed, resulting in consistent mechanical properties throughout the material. This uniformity enhances the steel's strength, toughness, and durability. High-quality steel billets also demonstrate excellent dimensional accuracy. They possess precise and consistent dimensions, which are vital for subsequent processing and manufacturing operations. This dimensional accuracy ensures that the billets can be easily formed, rolled, forged, or machined into their intended final shapes. Moreover, high-quality steel billets exhibit a superior surface finish. They are devoid of defects like cracks, voids, or inclusions on their surfaces. This smooth and defect-free surface allows for better heat transfer, improved corrosion resistance, and an enhanced aesthetic appearance of the final steel products. Lastly, high-quality steel billets showcase excellent metallurgical properties. They possess a well-controlled chemical composition, which determines their specific mechanical and physical characteristics. These properties can be tailored to meet the requirements of different applications, such as high strength, high ductility, or resistance to extreme temperatures. To summarize, high-quality steel billets possess properties such as purity, uniform internal structure, dimensional accuracy, excellent surface finish, and desirable metallurgical properties. These properties make them ideal for a wide range of applications, including the construction, automotive, aerospace, and manufacturing industries.

- Q: How are steel billets used in the shipbuilding industry?

- The shipbuilding industry relies heavily on steel billets, which are vital for constructing different parts and structures of ships. These billets serve as the raw material for making essential components like hulls, frames, bulkheads, and other structural elements. To meet the requirements of shipbuilding, steel must possess exceptional strength, durability, and resistance to corrosion. Steel billets are an ideal choice because of their high-quality composition and properties. Initially, these billets are shaped and formed into specific dimensions, depending on the ship's design needs. Once the steel billets are ready, they are used in various shipbuilding processes. One of their key applications is in building the ship's hull, which provides the necessary strength and buoyancy. Steel billets are cut and welded together to create the framework of the hull, ensuring the ship's structural integrity and stability. Additionally, steel billets are used in manufacturing frames, bulkheads, and decks. Frames offer structural support and rigidity to the ship's framework, while bulkheads divide the internal space into separate compartments, enhancing safety and preventing water ingress in case of damage. Decks, on the other hand, serve as the ship's floors on different levels. Furthermore, steel billets are utilized for fabricating various equipment and machinery installed on ships. These include propulsion systems, cranes, winches, and other heavy-duty components that contribute to the ship's functionality and operational capabilities. Overall, steel billets play a crucial role in the shipbuilding industry as they form the foundation for constructing ships and their essential components. Their high-quality steel and versatility enable shipbuilders to create vessels that meet stringent safety standards, withstand harsh marine conditions, and ensure long service life.

- Q: What are the different shapes of steel billets?

- Steel billets can come in various shapes, including square, round, rectangular, and hexagonal.

Send your message to us

Q235/3SP 85MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords