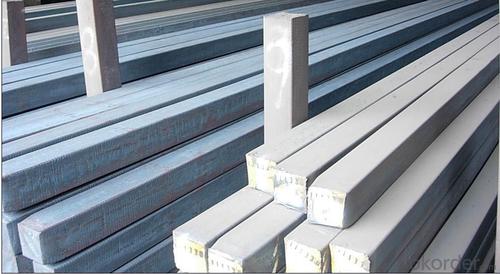

Q235/3SP 125MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Q235/3SP 125MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels consist of a steel substrate with a metallic zinc coating applied by means of a continuous hot dip galvanising process. Metallic zinc coatings are available in steel grades ranging from steel for bending and deep drawing applications, to structural steels and high yield strength steels.

A glossy surface finish obtained under specific skin-pass conditions (either non-skin-passed or skin- passed with smooth cylinders to obtain low roughness) can be provided if required at time of enquiry.

Advantage of Q235/3SP 125MM Blast Furnace Hot Rolled Steel Billet

Uncoated CR steel sheet With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Q235/3SP 125MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels can be used in a very wide range of applications for industrial markets, both indoors and outdoors. Some of the most common applications are:

Building: wide sections for roofing and cladding, doors, door frames, metallic ceilings, partitions, structural members etc

Domestic appliances: all appliances for this sector (both white and brown goods) are manufactured with hot dip galvanised steels

Miscellaneous: electrical cabinets, aeraulic components, air conditioners, road signs etc

Zinc hot dip galvanised steel is suitable for contact with foodstuffs under certain conditions, as specified in European directive 89/109/EEC and French standard NF A 36-712-1. Please contact us for further information on this subject.

Specifications of Q235/3SP 125MM Blast Furnace Hot Rolled Steel Billet

Quality | Q/BQB 440-2003 | JIS G3312-1994 JIS G3321 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | DC51D | SGCC SGLCC | DX51D+Z DX51D+AZ | CS Type A/B/C |

Forming Steel | St01,St02,St03 | SGCD1 SGLCD1 | FS Type A, Type B | |

Drawing | DC52D /DC53D | - | DX52D+Z DX52D+AZ | DDS TYPE A/C |

Steel | DX53D+Z DX53D+AZ | |||

Structural | S280GD (StE28) | SGC400 SGLC400 | S280D+Z DX54D+AZ | SS275 |

Steel | S350GD (StE34) | SGC440 SGLC440 | S350D+Z S350D+AZ | SS340 Class1 |

FAQ of Q235/3SP 125MM Blast Furnace Hot Rolled Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are the different types of cutting processes used for shaping steel billets?

- There are several different types of cutting processes used for shaping steel billets. These processes include: 1. Bandsaw cutting: Bandsaw cutting is a widely used method for cutting steel billets. It involves using a continuous band of toothed metal blade to cut through the billet. Bandsaws are known for their ability to cut through thick sections of steel quickly and accurately. 2. Abrasive cutting: Abrasive cutting involves using an abrasive wheel or disc to cut through the steel billet. This method is commonly used for cutting smaller billets or for cutting shapes and contours into the billet. Abrasive cutting is known for its versatility and ability to produce smooth and precise cuts. 3. Plasma cutting: Plasma cutting is a thermal cutting process that uses a high-velocity jet of ionized gas to melt and remove the steel from the billet. This method is often used for cutting thick sections of steel or for cutting intricate shapes. Plasma cutting is known for its speed and ability to produce clean cuts. 4. Waterjet cutting: Waterjet cutting is a process that uses a high-pressure jet of water to cut through the steel billet. In some cases, abrasive particles may be added to the water to enhance the cutting ability. Waterjet cutting is known for its ability to cut through thick sections of steel without creating heat-affected zones or distortion. 5. Laser cutting: Laser cutting involves using a high-powered laser beam to melt and vaporize the steel billet. The laser beam is guided by computer controls to cut the desired shape. Laser cutting is known for its precision and ability to cut intricate shapes with minimal distortion. These are just a few examples of the different types of cutting processes used for shaping steel billets. Each process has its own advantages and is chosen based on factors such as the size of the billet, the desired shape, and the required accuracy.

- Q: How do steel billets contribute to the manufacturing of consumer goods?

- Steel billets are a crucial raw material in the manufacturing of consumer goods as they serve as the base material for various steel products. These billets are used in processes such as forging, rolling, and extrusion to produce a wide range of consumer goods, including appliances, automobiles, construction materials, and machinery. The versatility, strength, and durability of steel make it an ideal choice for manufacturing consumer goods, and steel billets form the foundation for creating these high-quality and long-lasting products.

- Q: Are steel billets used in the production of construction equipment?

- Steel billets are a frequently employed resource in the manufacturing of construction equipment. Typically hot-rolled or forged, these semi-finished steel products assume diverse shapes and sizes. As a result, they serve as the foundational material for constructing elements like beams, plates, rods, and structural parts in construction equipment. By utilizing steel billets, the end product is fortified with durability, strength, and dependability, rendering it apt for demanding tasks within the construction sector.

- Q: What are the potential applications of steel billets in the automotive industry?

- Due to their exceptional strength and durability, steel billets offer a wide range of potential applications in the automotive industry. One notable use is in the manufacturing of automotive components such as engine blocks, crankshafts, and transmission parts. These components necessitate a material that can endure high temperatures, heavy loads, and repetitive stress, which steel billets can provide. Another significant application is in the production of chassis and body panels. Steel billets are frequently employed to construct the structural framework of a vehicle, ensuring safety and stability by delivering the necessary strength and rigidity. Additionally, steel billets can be shaped and sized in various ways, permitting the customization of chassis components to meet the specific requirements of different vehicle models. Steel billets are also utilized in the production of suspension systems and steering mechanisms. These parts require a material capable of absorbing vibrations, damping shocks, and providing precise control. Steel billets possess these properties, making them an ideal choice for these essential automotive components. Furthermore, steel billets find applications in the production of exhaust systems due to their ability to withstand high temperatures and corrosive environments. The resistance of steel to rust and corrosion guarantees the longevity of the exhaust system, contributing to the overall performance and efficiency of the vehicle. In conclusion, the potential applications of steel billets in the automotive industry are extensive. From engine components to chassis parts, suspension systems to exhaust systems, steel billets offer the required strength, durability, and versatility to meet the demanding needs of the automotive sector.

- Q: How are steel billets used in the production of transmission towers?

- Transmission towers require steel billets, which are semi-finished steel products, as a crucial component for their production. The first step in the process is to heat the steel billets in a furnace at extremely high temperatures. This hot rolling process softens the billets and makes them more malleable, enabling easy shaping and forming into the desired structure of the transmission tower. Once heated, the billets are then passed through rolling mills, where they are shaped into long, cylindrical sections known as steel bars. These bars are further processed and cut to the required length and dimensions based on the specific design and requirements of the transmission tower. Following the shaping and cutting, the steel bars undergo galvanization, which involves coating them with a protective layer of zinc. This zinc coating provides corrosion resistance, safeguarding the tower from environmental elements like moisture and rust. Finally, the galvanized steel bars are assembled and welded together to create the intricate framework of the transmission tower. The usage of strong and durable steel billets ensures that the tower can withstand heavy loads and extreme weather conditions. In conclusion, steel billets are essential for the production of transmission towers due to their strength, flexibility, and corrosion resistance. Their ability to be shaped and formed into the desired dimensions, along with their durability, make them an ideal material for constructing transmission towers.

- Q: What is the role of steel billets in the manufacturing of machinery?

- The versatile and desirable properties of steel billets make them a crucial component in machinery manufacturing. These semi-finished steel products, which are long and rectangular bars, serve as the raw material for creating different machinery components. To begin with, steel billets possess strength, durability, and excellent mechanical properties, making them perfect for heavy-duty machinery construction. By utilizing high-quality billets, manufacturers can ensure that the resulting machinery will have the necessary strength and structural integrity to withstand demanding operating conditions and loads. Additionally, steel billets can be easily molded and shaped into various forms and sizes through processes like forging, rolling, or extrusion. This versatility enables machinery manufacturers to produce intricate components with precise designs, ensuring accuracy and functionality. Moreover, the reliability and performance of machinery are enhanced by the uniformity and consistency of steel billets. During their production, billets undergo a controlled cooling process, resulting in a uniform microstructure. This minimizes the risk of defects and improves the overall quality of the machinery components made from them. Another significant aspect is the machinability of steel billets, which refers to their ease of cutting, drilling, or shaping using machine tools. This property allows manufacturers to efficiently produce machinery components with precise dimensions and tolerances, ultimately saving time and costs in the manufacturing process. Furthermore, steel billets can be heat-treated to enhance their mechanical properties, such as hardness, toughness, and resistance to wear or corrosion. This makes them suitable for critical machinery parts that require specific characteristics for optimal performance and longevity. In conclusion, steel billets are essential in machinery manufacturing due to their strength, versatility, uniformity, and machinability. They provide the necessary raw material for producing robust and reliable machinery components that can withstand demanding conditions and meet the performance requirements of various industries.

- Q: How do steel billets contribute to the overall seismic resistance of a structure?

- The overall seismic resistance of a structure is greatly improved by the presence of steel billets. When incorporated into concrete structures, steel billets act as reinforcement, boosting the structure's strength and longevity. This reinforcement enables the structure to better endure the forces and vibrations unleashed by earthquakes. The impressive tensile strength of steel billets enables them to efficiently absorb and distribute seismic energy, significantly decreasing the likelihood of structural failure during an earthquake. Moreover, steel billets have the capacity to be transformed into specialized structural elements, such as braces or shear walls, which are strategically positioned within the structure to counteract the lateral forces resulting from earthquakes. By utilizing steel billets, these structural elements are able to effectively absorb and disperse the seismic energy, successfully safeguarding the overall structure from substantial harm. Furthermore, steel billets are instrumental in the construction of seismic dampers, which are devices created to soak up and dissipate the energy generated by seismic events. When steel billet-based dampers are installed, the structure is able to significantly diminish the transfer of seismic energy to the building, thereby minimizing the potential for damage. Additionally, steel billets possess outstanding ductility, which is the capacity to deform without breaking. During an earthquake, structures experience considerable movement and vibrations. The ductile nature of steel allows it to flex and bend under these forces, proficiently absorbing seismic energy and preventing sudden, catastrophic failure of the structure. In conclusion, steel billets enhance the overall seismic resistance of a structure by providing additional strength and durability, facilitating the creation of specialized structural elements, enabling the construction of seismic dampers, and offering exceptional ductility. Their application elevates the structure's ability to withstand seismic forces, reducing the risk of damage and ensuring the safety of its occupants.

- Q: What is a steel billet?

- A steel billet is a semi-finished product that is created through the process of casting molten steel into a rectangular shape. It typically has a square or rectangular cross-section and is often used as a starting material for various steel products. The size of a steel billet can vary depending on its intended use, but it is typically around 100mm to 200mm square in cross-section and several meters long. Once produced, steel billets are further processed through rolling or extrusion to create different shapes such as bars, rods, wires, or structural steel sections. Steel billets are widely used in the manufacturing industry as a raw material for the production of a wide range of steel products used in construction, automotive, machinery, and many other sectors.

- Q: What industries use steel billets?

- Several industries use steel billets, including automotive, construction, manufacturing, and infrastructure. Steel billets are commonly used as raw material in the production of various metal products such as pipes, rods, bars, wires, and sheets. They are also utilized in the construction of bridges, buildings, and other structural components. The automotive industry uses steel billets for manufacturing parts like engine blocks, chassis, and suspension components. Additionally, steel billets find applications in the energy sector, machinery production, and shipbuilding.

- Q: After processing to the color coating board, is there a fare increase of 1000?The price of galvanized coil is about +350 per ton of cold-rolled steel at present What about the cost of billet to cold rolling?What is the final cost of making the color coated sheet? How do you figure that?

- I think that the cost of steel billet plus manual consumption plus electricity and other costs divided by the finished product is greater than the cost per ton

Send your message to us

Q235/3SP 125MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords