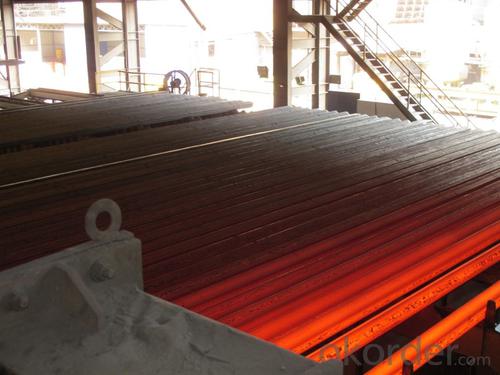

Q235/3SP 95MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Q235/3SP 95MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels consist of a steel substrate with a metallic zinc coating applied by means of a continuous hot dip galvanising process. Metallic zinc coatings are available in steel grades ranging from steel for bending and deep drawing applications, to structural steels and high yield strength steels.

A glossy surface finish obtained under specific skin-pass conditions (either non-skin-passed or skin- passed with smooth cylinders to obtain low roughness) can be provided if required at time of enquiry.

Advantage of Q235/3SP 95MM Blast Furnace Hot Rolled Steel Billet

Uncoated CR steel sheet With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Q235/3SP 95MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels can be used in a very wide range of applications for industrial markets, both indoors and outdoors. Some of the most common applications are:

Building: wide sections for roofing and cladding, doors, door frames, metallic ceilings, partitions, structural members etc

Domestic appliances: all appliances for this sector (both white and brown goods) are manufactured with hot dip galvanised steels

Miscellaneous: electrical cabinets, aeraulic components, air conditioners, road signs etc

Zinc hot dip galvanised steel is suitable for contact with foodstuffs under certain conditions, as specified in European directive 89/109/EEC and French standard NF A 36-712-1. Please contact us for further information on this subject.

Specifications of Q235/3SP 95MM Blast Furnace Hot Rolled Steel Billet

Quality | Q/BQB 440-2003 | JIS G3312-1994 JIS G3321 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | DC51D | SGCC SGLCC | DX51D+Z DX51D+AZ | CS Type A/B/C |

Forming Steel | St01,St02,St03 | SGCD1 SGLCD1 | FS Type A, Type B | |

Drawing | DC52D /DC53D | - | DX52D+Z DX52D+AZ | DDS TYPE A/C |

Steel | DX53D+Z DX53D+AZ | |||

Structural | S280GD (StE28) | SGC400 SGLC400 | S280D+Z DX54D+AZ | SS275 |

Steel | S350GD (StE34) | SGC440 SGLC440 | S350D+Z S350D+AZ | SS340 Class1 |

FAQ of Q235/3SP 95MM Blast Furnace Hot Rolled Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are the common applications of steel billets?

- Steel billets are commonly used as raw material for the production of various steel products, such as bars, rods, wire, pipes, and tubes. They are also utilized in the automotive industry for manufacturing parts like crankshafts, camshafts, and gears. Additionally, steel billets find applications in construction for producing structural elements like beams, columns, and girders.

- Q: What is the role of steel billets in the manufacturing of structural steel bridges?

- Structural steel bridges heavily rely on steel billets, which are essential semi-finished products utilized as the raw material for manufacturing various steel products, including these bridges. The initial step involves heating the steel billets and passing them through a series of rolling mills to shape them accordingly. This rolling process ensures that the billets are converted into elongated, slender sections suitable for bridge construction. Once the steel billets have been rolled into the desired forms, they undergo further processing and fabrication to create the necessary components for structural steel bridges. These components encompass beams, columns, girders, and other vital elements that contribute to the bridge's strength, stability, and load-bearing capabilities. The utilization of steel billets in the production of structural steel bridges provides numerous advantages. Firstly, steel possesses an exceptional strength-to-weight ratio, rendering it an ideal material for constructing bridges capable of withstanding heavy loads while remaining relatively lightweight. Moreover, steel's versatility allows for the creation of intricate bridge designs that can accommodate diverse architectural and engineering requirements. Furthermore, steel billets exhibit high durability and resistance to environmental factors like corrosion, which is crucial for ensuring the long-term integrity and safety of the bridge structure. This durability ultimately contributes to the bridge's extended lifespan, leading to reduced maintenance and replacement costs over time. In conclusion, steel billets serve as the fundamental building blocks for the manufacturing of structural steel bridges. Through the rolling and fabrication processes, these billets are transformed into various components that collectively provide strength, stability, and durability to the bridge. The utilization of steel billets enables the construction of bridges capable of withstanding heavy loads, maintaining a lightweight nature, and enduring environmental factors, thereby ensuring the bridge's long-term integrity and safety.

- Q: How are steel billets used in the production of axles?

- Steel billets are used in the production of axles as a starting material. They are heated and shaped through forging or rolling processes to form the desired axle shape. This ensures the axle has the necessary strength and durability to support the weight and withstand the forces experienced during operation.

- Q: What are the properties of steel billets?

- Steel billets, typically rectangular in shape, serve as the starting point for the production of various steel products. They possess several distinct properties that make them essential and versatile in various industries. Firstly, steel billets have exceptional strength due to the presence of carbon and other alloying elements. This high strength enables them to withstand heavy loads and provide structural integrity in different applications. Secondly, steel billets are highly ductile, meaning they can be easily deformed without fracturing. This ductility allows for the shaping and forming of the billets into different products through processes like rolling, forging, and extrusion. Thirdly, steel billets have good thermal conductivity, allowing them to efficiently transfer heat. This property is particularly useful in applications involving heat treatment or heat dissipation, such as the manufacturing of automotive parts or machinery. Additionally, depending on their composition and surface treatment, steel billets can exhibit a certain level of corrosion resistance. However, it is important to protect them properly to prevent rusting, potentially requiring measures like coatings or galvanization. Furthermore, steel billets are known for their machinability, meaning they can be easily cut, drilled, or milled into desired shapes and sizes. This property facilitates the production of intricate parts and components. Lastly, steel billets are highly recyclable, contributing to the sustainability of steel production. This not only reduces waste and environmental impact but also supports the circular economy. In conclusion, the properties of steel billets make them essential and versatile materials in industries such as construction, automotive, machinery, and manufacturing.

- Q: How are steel billets used in the manufacturing of electrical appliances?

- Steel billets are an essential component in the manufacturing process of electrical appliances. These billets are semi-finished steel products that are typically rectangular in shape. They are used as a raw material for various electrical appliance components. One of the primary uses of steel billets in electrical appliance manufacturing is in the production of motor cores. Motor cores are crucial components in electric motors, which are utilized in various electrical appliances such as refrigerators, washing machines, and air conditioners. The steel billets are processed and shaped into laminated cores, which are then stacked together to form the motor core. These cores provide the structural support and magnetic properties necessary for the motor to generate rotational motion. Furthermore, steel billets are also used in the production of electrical wires and cables. These wires and cables are crucial for transmitting electricity within electrical appliances. The steel billets are processed and drawn into thin wires, which are then insulated and bundled to form the necessary electrical connections within the appliances. Additionally, steel billets find application in the manufacturing of electrical appliance housings and frames. These components provide the necessary structural support and protective covering for the internal electrical components. Steel billets are processed and molded into the desired shapes and sizes to create durable and rigid housings that can withstand the stress and environmental conditions of everyday usage. Overall, steel billets play a vital role in the manufacturing of electrical appliances by providing the raw material for motor cores, electrical wires, cables, and housing components. Their strength, durability, and magnetic properties make them an ideal choice for ensuring the quality and performance of electrical appliances.

- Q: What are the main uses of steel billets?

- Steel billets are semi-finished steel products that are commonly used in various industries. The main uses of steel billets include: 1. Steel production: Steel billets serve as the starting point for the production of various steel products. They are used in the manufacturing of bars, rods, wire, and structural sections, among other steel products. 2. Construction industry: Steel billets are extensively used in the construction industry for the production of beams, columns, and other structural elements. These billets are often rolled into specific shapes and sizes to meet the demands of construction projects. 3. Automotive industry: Steel billets are used in the automotive industry for the production of various components, such as crankshafts, camshafts, axles, and gears. These billets are further processed to form the desired shapes and sizes required for these components. 4. Machinery and equipment manufacturing: Steel billets find applications in the manufacturing of machinery and equipment. They are used to produce parts and components that require high strength and durability, such as gears, shafts, and bearings. 5. Pipe and tube manufacturing: Steel billets are an essential raw material used in the production of pipes and tubes. They are heated and pierced to form seamless tubes or rolled and welded to produce welded tubes. These tubes find applications in various industries, including oil and gas, construction, and automotive. 6. Forging industry: Steel billets are widely used in the forging industry for the production of forged components, such as crankshafts, connecting rods, and valves. The billets are heated and then shaped using pressure and heat to achieve the desired shape and strength. 7. Shipbuilding industry: Steel billets are utilized in the shipbuilding industry for the construction of ship hulls, frames, and other structural components. These billets provide the necessary strength and durability required for marine applications. In summary, steel billets serve as the raw material for the production of a wide range of steel products used in various industries, including construction, automotive, machinery manufacturing, pipe and tube manufacturing, forging, and shipbuilding.

- Q: How are steel billets used in the production of marine equipment?

- Steel billets are used in the production of marine equipment as they are the starting point for various manufacturing processes. They are heated, shaped, and machined into different components such as hulls, propellers, and structural supports, which are then assembled to create the final marine equipment.

- Q: What are the specifications for steel billets used in the aerospace industry?

- The aerospace industry demands highly precise and stringent specifications for steel billets. These billets must adhere to specific standards to guarantee the safety and durability of aircraft components. Firstly, the steel utilized for aerospace billets must possess outstanding strength and toughness. It must exhibit a high tensile strength and the ability to withstand extreme forces and stresses encountered during flight. Additionally, the steel must demonstrate excellent fracture resistance to minimize the risk of catastrophic failure. Moreover, the steel billets must possess exceptional resistance to corrosion and oxidation. This is crucial as aircraft frequently operate in harsh environments, such as high altitudes and exposure to various chemicals. The steel should resist rust, pitting, and other forms of degradation that can compromise its structural integrity over time. Furthermore, the steel billets employed in aerospace applications must exhibit precise dimensional tolerances and uniformity. They should be manufactured according to exact specifications to ensure consistency in the production of aircraft components. This entails precise size, shape, and surface finish, which are vital for proper fitting and assembly. Regarding chemical composition, the steel used for aerospace billets may vary depending on the specific application and component being manufactured. However, it typically includes elements like carbon, manganese, chromium, nickel, and molybdenum. These alloying elements enhance the mechanical properties of the steel, such as hardness, toughness, and heat resistance. Additionally, the steel billets utilized in the aerospace industry undergo rigorous testing and quality control procedures. This includes non-destructive testing methods such as ultrasonic inspection, magnetic particle inspection, and dye penetrant inspection to identify any internal defects or discontinuities. In summary, the specifications for steel billets used in the aerospace industry encompass exceptional strength, toughness, corrosion resistance, dimensional accuracy, and precise chemical composition. These stringent requirements ensure the reliability and safety of aircraft components, enabling them to withstand the demanding conditions experienced during flight.

- Q: How do steel billets contribute to the energy sector?

- Steel billets are an essential component in the energy sector for various reasons. Firstly, they are used in the construction of power plants and energy infrastructure. Steel billets are often used to fabricate structures such as beams, columns, and support systems that are critical for the stability and safety of these facilities. These structures provide the necessary framework to house generators, turbines, and other equipment required for energy production. Moreover, steel billets are used in the manufacturing of pipelines and storage tanks for the transportation and storage of various energy resources. Whether it is oil, natural gas, or even renewable energy sources like hydrogen, steel billets are used to create durable and reliable pipeline systems that can withstand high pressures and harsh environmental conditions. Similarly, steel billets are used in the construction of storage tanks that hold energy resources, ensuring their safe storage and easy access when needed. Steel billets also play a vital role in the production of wind turbines. The towers of wind turbines are often made from steel billets due to their high strength and durability. These towers support the blades and nacelle, which house the generator and other components. The ability of steel billets to withstand extreme weather conditions and support the weight of the turbine is crucial for the efficient and reliable generation of wind energy. Furthermore, steel billets are used in the manufacturing of equipment and machinery utilized in the extraction and exploration of energy resources. For example, drilling rigs and equipment used in oil and gas exploration are often constructed using steel billets due to their high tensile strength and resistance to corrosion. This enables efficient and safe drilling operations, contributing to the overall energy production process. In conclusion, steel billets contribute significantly to the energy sector by providing the necessary infrastructure, pipelines, storage tanks, and equipment required for energy production, transportation, and exploration. Their strength, durability, and versatility make them an essential component in the construction and functioning of power plants, pipelines, wind turbines, and various other energy-related applications.

- Q: How do steel billets contribute to the overall strength of a structure?

- Steel billets contribute to the overall strength of a structure by serving as the raw material for various structural components. They are made from molten steel that is solidified into a rectangular shape, resulting in a dense and homogeneous material. These billets are then further processed and formed into beams, columns, and other load-bearing elements. Their high strength and durability allow them to withstand heavy loads and forces, enhancing the overall structural integrity of the building or infrastructure.

Send your message to us

Q235/3SP 95MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords