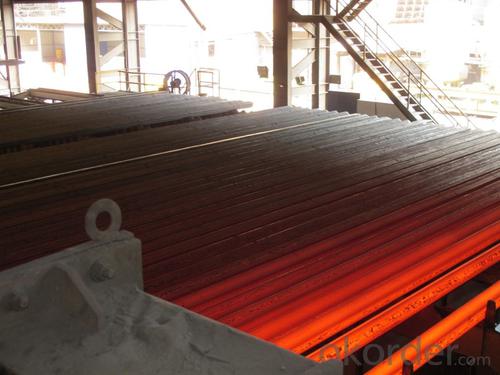

Q235/3SP 70MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Q235/3SP 70MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels consist of a steel substrate with a metallic zinc coating applied by means of a continuous hot dip galvanising process. Metallic zinc coatings are available in steel grades ranging from steel for bending and deep drawing applications, to structural steels and high yield strength steels.

A glossy surface finish obtained under specific skin-pass conditions (either non-skin-passed or skin- passed with smooth cylinders to obtain low roughness) can be provided if required at time of enquiry.

Advantage of Q235/3SP 70MM Blast Furnace Hot Rolled Steel Billet

Uncoated CR steel sheet With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Q235/3SP 70MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels can be used in a very wide range of applications for industrial markets, both indoors and outdoors. Some of the most common applications are:

Building: wide sections for roofing and cladding, doors, door frames, metallic ceilings, partitions, structural members etc

Domestic appliances: all appliances for this sector (both white and brown goods) are manufactured with hot dip galvanised steels

Miscellaneous: electrical cabinets, aeraulic components, air conditioners, road signs etc

Zinc hot dip galvanised steel is suitable for contact with foodstuffs under certain conditions, as specified in European directive 89/109/EEC and French standard NF A 36-712-1. Please contact us for further information on this subject.

Specifications of Q235/3SP 70MM Blast Furnace Hot Rolled Steel Billet

Quality | Q/BQB 440-2003 | JIS G3312-1994 JIS G3321 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | DC51D | SGCC SGLCC | DX51D+Z DX51D+AZ | CS Type A/B/C |

Forming Steel | St01,St02,St03 | SGCD1 SGLCD1 | FS Type A, Type B | |

Drawing | DC52D /DC53D | - | DX52D+Z DX52D+AZ | DDS TYPE A/C |

Steel | DX53D+Z DX53D+AZ | |||

Structural | S280GD (StE28) | SGC400 SGLC400 | S280D+Z DX54D+AZ | SS275 |

Steel | S350GD (StE34) | SGC440 SGLC440 | S350D+Z S350D+AZ | SS340 Class1 |

FAQ of Q235/3SP 70MM Blast Furnace Hot Rolled Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: Are steel billets used in the production of household goods?

- No, steel billets are typically not used in the production of household goods. They are usually used as raw materials in steel mills for the production of various steel products, such as bars, rods, pipes, and structural components.

- Q: Can steel billets be used in the production of energy-efficient appliances?

- Certainly, energy-efficient appliances can make use of steel billets. Steel, being a versatile material renowned for its strength and durability, is extensively employed in appliance manufacturing. These appliances are designed to minimize energy consumption and greenhouse gas emissions by employing less energy while performing their designated tasks. When it comes to energy-efficient appliances, steel billets can be processed and transformed into numerous components, including outer shells, structural supports, and internal parts. The incorporation of steel ensures the longevity and dependability of these appliances, thereby enhancing their overall energy efficiency. Moreover, steel is highly recyclable, allowing it to be repurposed or reused for other applications once an appliance reaches the end of its lifecycle. Steel recycling aids in energy conservation and waste reduction, further bolstering the pursuit of energy efficiency. To summarize, the utilization of steel billets is indeed feasible in the production of energy-efficient appliances. The exceptional properties of steel, namely its strength, durability, and recyclability, make it an ideal choice for manufacturing appliances that promote a more sustainable future.

- Q: What are the different types of surface finish methods used for steel billets?

- There are several types of surface finish methods used for steel billets, each serving different purposes and achieving distinct surface characteristics. These methods include: 1. Hot rolling: This method involves passing the steel billet through a series of heated rollers, which compress and shape the material. The hot rolling process creates a smooth and glossy surface finish on the steel billet. 2. Shot blasting: In shot blasting, small metallic or non-metallic particles are propelled at high speeds onto the surface of the steel billet. This process removes any scale, rust, or contaminants, resulting in a clean and textured surface finish. 3. Pickling: Pickling is a chemical process that involves immersing the steel billet in an acid solution to remove any oxide scale or surface impurities. This method provides a smooth and corrosion-resistant surface finish. 4. Grinding: Grinding involves using abrasive wheels or belts to remove material from the surface of the steel billet. This process can be used to achieve a precise and smooth surface finish for various applications. 5. Polishing: Polishing is a mechanical process that uses abrasive materials to remove any imperfections or roughness from the surface of the steel billet. This method results in a high-gloss, mirror-like finish. 6. Cold rolling: Similar to hot rolling, cold rolling involves passing the steel billet through a series of rollers. However, in this process, the steel billet is not heated, resulting in a smoother and more precise surface finish. 7. Coating: Coating is a surface finish method that involves applying a protective layer or coating onto the steel billet. This can include paints, varnishes, or specialized coatings to enhance the appearance, durability, or corrosion resistance of the steel billet. Each of these surface finish methods has its advantages and is chosen based on the desired application, aesthetics, and functional requirements of the steel billet.

- Q: How do steel billets contribute to the water treatment industry?

- Steel billets are used in the water treatment industry to manufacture various components such as pipes, valves, and fittings. These components are vital for the construction and maintenance of water treatment infrastructure. Steel billets provide the necessary strength, durability, and corrosion resistance needed to withstand harsh conditions and chemicals involved in water treatment processes. Thus, steel billets play a crucial role in ensuring the efficiency and longevity of water treatment systems.

- Q: What are the common uses of steel billets?

- Steel billets, serving as a precursor to different steel products, are semi-finished metal goods. They typically take on a solid, rectangular shape through continuous casting or hot rolling. Steel billets find wide application in various industries due to their strength and versatility. One of the primary uses of steel billets is in the production of long steel products like bars, rods, and wires. These billets act as the initial material for further processing, where they are reheated and shaped into the desired form. Long steel products are extensively employed in construction, infrastructure development, manufacturing, and transportation industries. Steel billets are also utilized in the manufacturing of seamless pipes and tubes. Through the process of piercing and elongation, the billets can be converted into seamless tubes, which are widely employed in oil and gas exploration, automotive manufacturing, and structural engineering. Moreover, steel billets play a vital role in producing forged steel components. Forging involves shaping the heated billet under pressure, resulting in durable and high-strength products. These forged components find wide application in industries such as aerospace, automotive, and power generation. Additionally, steel billets are used in the production of various other steel products, including beams, channels, and profiles for construction purposes, as well as machine parts and tools. In conclusion, steel billets serve as the starting material for the production of long steel products, seamless pipes, forged components, and other steel goods. Their malleability, strength, and versatility make steel billets an indispensable raw material in numerous industries.

- Q: How are steel billets used in the manufacturing of valves and pumps?

- Steel billets are an essential raw material used in the manufacturing of valves and pumps. Billets are semi-finished steel products that are cast into a specific shape, usually in the form of a square or a rectangle. These billets serve as the starting point for the production of valves and pumps. To manufacture valves, steel billets are first heated and then forged or rolled into the desired shape. The billets undergo a series of processes such as cutting, drilling, and machining to form the various components of a valve, including the body, bonnet, disc, stem, and seat. These components are then assembled to create the valve, which regulates the flow of fluids or gases in a system. Similarly, in the manufacturing of pumps, steel billets are heated and shaped into the necessary parts such as impellers, casings, shafts, and housings. These components are then assembled to create a pump, which is responsible for moving fluids or gases from one place to another. The use of steel billets in the manufacturing of valves and pumps is crucial due to the inherent properties of steel. Steel is known for its strength, durability, and resistance to corrosion, making it ideal for applications in industries where valves and pumps are subjected to high pressures, temperatures, and corrosive environments. Furthermore, the versatility of steel allows for customization, enabling manufacturers to create valves and pumps of various sizes, shapes, and specifications to meet the specific needs of different industries and applications. This adaptability ensures that valves and pumps made from steel billets can perform reliably and efficiently in a wide range of environments and conditions. In conclusion, steel billets play a vital role in the manufacturing of valves and pumps. Through the forging, shaping, and assembly processes, steel billets are transformed into the essential components that make up these crucial industrial devices. The use of steel ensures the strength, durability, and corrosion resistance required for valves and pumps to function effectively and withstand demanding operating conditions.

- Q: Can steel billets be used in the production of energy infrastructure?

- Yes, steel billets can be used in the production of energy infrastructure. Steel is a widely used material in the construction of various energy infrastructure components such as power plants, transmission towers, pipelines, and wind turbine towers. Steel billets, which are semi-finished steel products, can be further processed and shaped into the required forms for these infrastructure projects. The strength, durability, and versatility of steel make it suitable for withstanding the harsh conditions and heavy loads associated with energy infrastructure. Additionally, steel offers excellent corrosion resistance, which is crucial for infrastructure exposed to the elements. Overall, steel billets play a vital role in the production of energy infrastructure, contributing to the reliable and efficient generation, transmission, and distribution of energy.

- Q: What are the international standards or certifications for steel billets?

- The international standards or certifications for steel billets include ASTM A615/A615M-20, ASTM A706/A706M-16, BS 4449:2005+A3:2016, and EN 10025-2:2004. These standards provide specifications for the chemical composition, mechanical properties, and dimensions of steel billets, ensuring their quality and suitability for various applications in the construction industry.

- Q: What are the different types of rolling processes used for shaping steel billets?

- There are several different types of rolling processes used for shaping steel billets. Some of the commonly used processes include hot rolling, cold rolling, ring rolling, and skew rolling. Each process has its own advantages and is suitable for specific applications. Hot rolling involves heating the steel billet to a high temperature and then passing it through a series of rollers to shape it. Cold rolling, on the other hand, is performed at room temperature and is used to achieve tighter tolerances and improved surface finish. Ring rolling is used to produce seamless rings by gradually shaping the billet using a combination of axial and radial forces. Skew rolling is a specialized process used for producing balls or cylindrical shapes by rotating the billet at an angle to the rolling direction. Overall, these rolling processes offer various techniques to shape steel billets according to specific requirements.

- Q: How are steel billets used in the manufacturing of construction scaffolding?

- The manufacturing of construction scaffolding relies heavily on steel billets, which are an indispensable raw material. Initially, the billets are heated and then passed through rolling mills to achieve the desired shape and size for scaffolding components. Once the steel billets have been rolled to the required shape, they undergo further processing to create different scaffolding parts such as tubes, couplers, frames, and planks. These parts are then assembled together to form the scaffolding structure, which provides a secure and stable platform for workers during construction projects at elevated heights. There are several advantages to using steel billets in the manufacturing of construction scaffolding. Firstly, steel is renowned for its exceptional strength and durability, making it an ideal material for scaffolding. Additionally, it is resistant to corrosion and capable of withstanding harsh weather conditions, ensuring the scaffolding remains reliable and safe throughout the construction process. Furthermore, steel scaffolding is highly versatile and can be easily customized to meet various project requirements. By using steel billets, manufacturers can create scaffolding components of different sizes, shapes, and configurations to accommodate diverse construction needs. In conclusion, steel billets play a crucial role in the manufacturing of construction scaffolding. By utilizing these raw materials, scaffolding manufacturers can produce scaffolding structures that are durable, reliable, and customizable, ultimately enhancing safety and efficiency on construction sites.

Send your message to us

Q235/3SP 70MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords