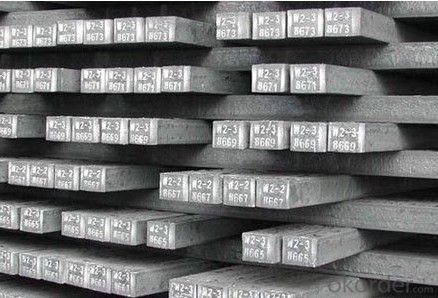

20MnSi Prime Steel Billet 150x150mm 120*120mm

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering 20MnSi Prime Steel Billet 150x150mm 120*120mm at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

20MnSi Prime Steel Billet 150x150mm 120*120mm are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's 20MnSi Prime Steel Billet 150x150mm 120*120mm are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: 20MnSi

Certificates: ISO, SGS, BV

size:60*60/90*90/100*100/120*120/150*150

Length: 6m/12m,

Packaging: Export packing, nude packing, bundled

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Images:

- Q: Are steel billets used in the production of electrical appliances?

- No, steel billets are not typically used in the production of electrical appliances. Electrical appliances are usually made from materials like plastic, aluminum, or stainless steel.

- Q: How do steel billets contribute to the manufacturing of tools and equipment?

- Tools and equipment manufacturing relies heavily on steel billets, which serve as a crucial component. These semi-finished steel products play a vital role in shaping and forming the final products used across different industries. To begin with, steel billets function as raw materials during the production of various tools and equipment. They act as the starting point for processes like forging, rolling, and extrusion. These processes involve heating and shaping the steel billets to achieve the desired form and dimensions of the tools and equipment. Furthermore, steel billets possess several advantages that make them suitable for tool and equipment manufacturing. The strength and durability of steel make it an ideal material for tools that need to endure heavy loads and harsh conditions. Additionally, the versatility of steel allows for the production of a wide range of tools and equipment, including cutting tools, machine parts, construction equipment, and automotive components. Moreover, steel billets can be easily machined and formed into complex shapes, enabling the production of intricate tools and equipment that meet specific requirements. The excellent machinability of steel allows for precise cutting, drilling, and milling processes, resulting in accurate dimensions and smooth surfaces. Additionally, steel billets can undergo heat treatment to enhance their mechanical properties, such as hardness and toughness. Processes like quenching and tempering can significantly improve the performance and longevity of tools and equipment. When combined with the inherent strength of steel, these processes ensure that the final products have the necessary strength, hardness, and wear resistance to effectively fulfill their intended functions. In conclusion, steel billets are indispensable in the manufacturing of tools and equipment due to their raw material capabilities and advantageous properties. They provide a reliable and versatile starting point for producing various tools and equipment, enabling the creation of durable, precise, and high-performance products that are vital to numerous industries.

- Q: What are the main factors affecting the machinability of alloy steel billets?

- Several key factors influence the machinability of alloy steel billets. Firstly, the machinability can be affected by the alloy composition of the steel. Different alloying elements, including chromium, nickel, molybdenum, and vanadium, have varying impacts on the machinability. Chromium and molybdenum, which form hard carbides, tend to decrease machinability, while nickel and vanadium, which promote the formation of softer carbides, can enhance machinability. Secondly, the heat treatment of the alloy steel billets significantly impacts machinability. Processes such as annealing, normalizing, or quenching and tempering can alter the microstructure and hardness of the steel. Proper heat treatment can improve machinability by reducing hardness and increasing toughness, while improper heat treatment can result in increased hardness and decreased machinability. Thirdly, the presence of impurities and inclusions in the alloy steel billets can affect machinability. Inclusions, such as sulfides, oxides, and non-metallic particles, can cause tool wear and chip breakability issues during machining. Therefore, the cleanliness and purity of the alloy steel billets are crucial factors in determining machinability. Furthermore, the mechanical properties of the alloy steel, such as hardness, strength, and ductility, can influence machinability. Higher hardness and strength levels can make machining more challenging, while increased ductility and toughness can improve machinability. Lastly, the cutting conditions and machining parameters, including cutting speed, feed rate, depth of cut, and tool material, also impact machinability. Optimal cutting conditions should be selected based on the specific alloy steel composition and desired machinability. Adequate cooling and lubrication during machining are also essential to reduce friction and heat, preventing tool wear and improving machinability. In conclusion, the machinability of alloy steel billets is influenced by factors such as alloy composition, heat treatment, impurities and inclusions, mechanical properties, and cutting conditions. Proper consideration of these factors can help optimize the machinability of alloy steel and ensure efficient and effective machining processes.

- Q: How are steel billets used in the manufacturing of castings?

- Steel billets are an important raw material in the manufacturing of castings. Castings are solid metal objects that are formed by pouring molten metal into a mold and allowing it to cool and solidify. Steel billets are typically used as the starting material for this process. To create castings, steel billets are first heated to a high temperature until they become molten. This molten steel is then poured into a mold, which is typically made of sand or metal. The mold is designed to have the desired shape and dimensions of the final casting. Once the molten steel is poured into the mold, it is left to cool and solidify. As the steel cools, it takes on the shape of the mold, forming the desired casting. The cooling process is critical as it determines the strength, hardness, and other mechanical properties of the final product. After the steel has solidified, the mold is removed, and the casting is cleaned and finished. This may involve removing any excess material, such as gates or risers, that were used to facilitate the pouring of the molten metal. The casting may also undergo additional processes, such as machining or heat treatment, to achieve the desired final specifications. In summary, steel billets are used in the manufacturing of castings by being melted and poured into a mold to create the desired shape. The cooling and solidification of the molten steel within the mold results in the formation of a solid casting, which can then be further processed and finished as required.

- Q: How are steel billets used in the production of automotive frames?

- Steel billets are used in the production of automotive frames as a primary raw material. Billets are essentially long, rectangular-shaped pieces of steel that are heated and then formed into specific shapes through various manufacturing processes. In the case of automotive frames, these billets are typically heated and then passed through a series of dies and rollers to form the desired shape and dimensions. Once the billets are formed into the appropriate shape, they are further processed through cutting, bending, and welding techniques to create the intricate and sturdy structure of an automotive frame. The use of steel billets in the production of automotive frames is preferred due to the high strength and durability properties of steel, which are crucial for ensuring the safety and structural integrity of the vehicles. Moreover, steel billets offer excellent formability and machinability, allowing manufacturers to create complex frame designs that meet the specific requirements of different vehicle models. Additionally, steel is a cost-effective material, making it a popular choice for mass production in the automotive industry. Overall, steel billets play a vital role in the production of automotive frames by providing a strong and reliable foundation for the vehicle's structure. The use of these raw materials, along with advanced manufacturing techniques, ensures that automotive frames are able to withstand various forces and impacts, ultimately contributing to the overall safety and performance of the vehicles.

- Q: How are steel billets used in the manufacturing of hydraulic equipment?

- Steel billets are commonly used in the manufacturing of hydraulic equipment as they serve as the raw material for creating various components, such as cylinders, valves, and pistons. These billets are heated and then shaped through forging or extrusion processes to form the desired hydraulic equipment parts. The strength, durability, and versatility of steel make it a preferred material choice for hydraulic equipment, enabling it to withstand the high pressures and demanding working conditions in this industry.

- Q: How are steel billets used in the production of oil and gas exploration equipment?

- Steel billets are commonly used in the production of oil and gas exploration equipment due to their strength and durability. These billets are shaped and machined into various components such as valves, pumps, drilling tools, and pipelines, which are crucial for the extraction and transportation of oil and gas. The high-quality steel ensures that the equipment can withstand harsh operating conditions, including high temperatures, pressure, and corrosive environments, thereby ensuring the safety and reliability of oil and gas exploration operations.

- Q: What are the different surface finishes available for alloy steel billets?

- Alloy steel billets offer a variety of surface finishes to cater to specific requirements and applications. Among the most commonly used surface finishes are: 1. Hot rolled: The prevalent surface finish, obtained by subjecting the steel billet to high temperatures during the rolling process. This results in a rough and scaled surface. 2. Cold drawn: Achieved by pulling the steel billet through a die at room temperature. It yields a smooth and polished surface, enhancing dimensional accuracy and surface quality. 3. Peeled: Involves removing a layer of material from the steel billet's surface using a peeling tool. This process produces a smooth and shiny surface finish, improving both surface quality and dimensional accuracy. 4. Ground: Accomplished by grinding the surface of the steel billet using abrasive wheels or belts. It delivers a smooth and even surface finish, enhancing both surface quality and dimensional accuracy. 5. Turned: In this process, a cutting tool is used to rotate the steel billet, removing material from the surface and creating a smooth and polished finish. It is particularly useful for high precision applications that require a smooth surface finish. 6. Polished: Achieved by polishing the steel billet using abrasive compounds and buffing wheels. This method provides a mirror-like finish, enhancing aesthetic appeal and corrosion resistance. It is crucial to carefully select the appropriate surface finish based on specific requirements such as dimensional accuracy, surface quality, aesthetic appeal, and corrosion resistance.

- Q: How are steel billets used in the production of power generation equipment?

- Steel billets are used in the production of power generation equipment due to their strength, durability, and versatility. Power generation equipment, such as turbines and generators, require sturdy and reliable components to withstand the harsh operating conditions and provide uninterrupted power supply. Steel billets, which are small, semi-finished steel products, serve as the raw material for manufacturing various parts of power generation equipment. They are typically melted down and cast into specific shapes to create components such as turbine blades, shafts, casings, and rotors. The use of steel billets in power generation equipment ensures high structural integrity, as steel is known for its excellent mechanical properties. It possesses high tensile strength, allowing it to withstand the extreme rotational forces and pressures experienced within turbines and generators. Additionally, steel exhibits good resistance to corrosion and high temperatures, making it ideal for use in power generation equipment that operates in harsh environments. Furthermore, steel billets can be easily machined and welded, allowing for precise manufacturing and assembly of complex parts. This flexibility in shaping and joining steel billets enables the production of customized components tailored to the specific requirements of power generation equipment. In summary, steel billets play a crucial role in the production of power generation equipment by providing a strong, durable, and versatile material for creating various components. Their use ensures the reliability and longevity of power generation equipment, allowing for efficient and uninterrupted power generation.

- Q: What is the role of steel billets in the production of valves and fittings?

- Steel billets play a crucial role in the production of valves and fittings. Valves and fittings are essential components in various industries, including oil and gas, petrochemical, water treatment, and many others. These components need to be strong, durable, and able to withstand high pressure and temperature conditions. Steel billets, which are semi-finished products made from molten steel, serve as the starting material for the production of valves and fittings. They are typically cast into specific shapes and sizes, such as round, square, or rectangular, to meet the requirements of the final product. The use of steel billets allows manufacturers to ensure consistent quality and performance of valves and fittings. The billets are carefully selected based on their chemical composition, mechanical properties, and microstructure, ensuring that they possess the necessary characteristics for the desired end product. Once the steel billets are obtained, they undergo various manufacturing processes, such as forging, machining, and heat treatment, to shape them into the final valve and fitting components. These processes help enhance the strength, integrity, and functionality of the products. Steel billets also offer versatility in terms of customization. They can be easily cut, shaped, and formed to create valves and fittings with different configurations, sizes, and designs, meeting the specific requirements of different applications and industries. Overall, steel billets are essential in the production of valves and fittings as they provide the raw material from which these components are made. Their strength, durability, and ability to be customized make them a critical element in ensuring the reliability and performance of valves and fittings in various industrial settings.

Send your message to us

20MnSi Prime Steel Billet 150x150mm 120*120mm

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords