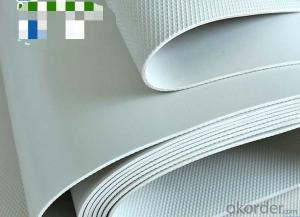

PVC Root Puncture Resistant Waterproof Membrane with Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Waterproofing Membrane:

PVC waterproofing membrane is an excellent high-quality polymer waterproof sheet, made of PVC

resin by adding plasticizer, anti-UV agent, anti aging agent, and stabilizer and other processing

aids through extrusion and molding.

As the highlyrecommended product by the Ministry of Construction, it is featured by high tensile strength,

great elongation, good stability, small shrinkage, low-temperature performances, good resistance to

weathering and root penetration, and long service life.

Specification of PVC Waterproofing Membrane:

Item | Specification |

Length | 20m |

Width | 1.05m, 2.05m,2.1m |

Thickness | 0.8mm,1.0mm;1.2mm;1.5mm;2.0mm |

Type of PVC Waterproofing Membrane:

Type H is the principal material used on exposed roof applications, in vacuum or mechanically attached

systems. These roofing systems are suitable for new build and refurbishment applications, flat and

pitched roofs. It is reliable, and convenient for construction.

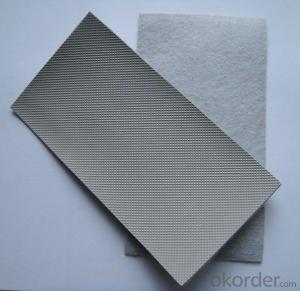

Type L is manufactured from pliable PVC with a reinforcement of non-woven polyester. The PVC contains stabilizers, which make the product resistant to

high and low temperatures, UV-resistant and makes it flame retardant.

Type P is H with a laminated polyester fleece (or glass fiber fleece) on its interlayer and

can be installed directly on old roofing underlay. We recommend that all roofs have

an inclination of minimum 1:40 to provide positive drainage.

Use scope of PVC Waterproofing Membrane:

1. The waterproofing of the Industrial or civil construction's roof, including the planting roof, flat roof, sloping roof.

2. Waterproofing of the underground building: Including reservoirs, dams, canals, and all parts of the basement water seepage.

3. Tunnel, granary, civil air defense projects, garbage landfills, and other man-made lake.

FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: How thick should a waterproofing membrane be applied?

- A waterproofing membrane should typically be applied to a thickness of at least 1.5mm to ensure effective protection against water infiltration.

- Q: How does a waterproofing membrane handle temperature fluctuations?

- A waterproofing membrane is designed to withstand temperature changes through its flexibility and resistance to thermal expansion and contraction. Temperature fluctuations have the potential to cause cracks, leaks, and other damage to materials. However, a waterproofing membrane is typically made from durable and flexible materials like PVC or EPDM, which can endure these temperature changes without compromising their effectiveness. When faced with high temperatures, the membrane will slightly expand to accommodate the increased thermal energy. Conversely, when temperatures decrease, the membrane will contract to maintain its integrity. This flexibility allows the membrane to adapt to changing conditions without cracking or becoming brittle. Besides flexibility, a waterproofing membrane is also engineered to resist the sun's UV radiation. Over time, UV radiation can cause materials to deteriorate, resulting in decreased performance and possible leaks. By incorporating UV stabilizers into the membrane's composition, it can endure prolonged exposure to sunlight and maintain its durability even in harsh weather conditions. Furthermore, certain waterproofing membranes possess built-in insulation properties that regulate temperature fluctuations. These membranes provide additional thermal resistance, reducing heat loss in cold weather and minimizing heat gain in hot weather. This insulation layer stabilizes the temperature of the underlying structure, preventing damage caused by extreme temperature changes. Overall, a waterproofing membrane is designed to handle temperature fluctuations by being flexible, resistant to thermal expansion and contraction, and capable of withstanding UV radiation. These attributes guarantee that the membrane remains intact and effective in safeguarding the underlying structure from water damage, regardless of the surrounding temperature conditions.

- Q: Are there any specific requirements for installing a waterproofing membrane?

- Yes, there are specific requirements for installing a waterproofing membrane. Some key requirements include ensuring a clean and dry surface, proper preparation of the substrate, correct application of the membrane according to manufacturer's instructions, and adequate curing time. Additionally, ensuring proper seam and joint treatments, as well as sufficient overlap and termination details, are essential for an effective waterproofing installation. It is crucial to follow the specific guidelines and recommendations provided by the manufacturer to ensure a successful and long-lasting waterproofing system.

- Q: Can a waterproofing membrane be used for water features or fountains?

- Indeed, a waterproofing membrane is suitable for water features or fountains. Specifically engineered to obstruct water infiltration, these membranes are an excellent option for water-related purposes. They establish a barricade that confines water within the intended space, warding off any leaks or seepage. Moreover, certain waterproofing membranes possess supplementary attributes, such as UV ray and chemical resistance, which prove advantageous for water features or fountains exposed to sunlight or treated with water treatment chemicals. In summary, the utilization of a waterproofing membrane guarantees the preservation of water features or fountains' impermeability and functionality.

- Q: Can waterproofing membranes be used on concrete fountains?

- Concrete fountains, which are frequently subjected to water and susceptible to leaks and moisture damage, can benefit from the application of waterproofing membranes. These membranes serve as a barrier that prevents water penetration and safeguards the structure of the fountain. Designed to be flexible, durable, and resistant to water, waterproofing membranes provide an optimal solution for concrete fountains. They can be applied to both the interior and exterior surfaces of the fountain, ensuring comprehensive protection against water damage. By utilizing waterproofing membranes, the lifespan of the concrete fountain can be prolonged, and maintenance expenses can be minimized.

- Q: Is a waterproofing membrane resistant to chemicals?

- Yes, a waterproofing membrane is generally resistant to chemicals. Waterproofing membranes are designed to provide a protective barrier against water and moisture, and they are often made of materials that are chemically resistant. However, the level of chemical resistance may vary depending on the specific type of membrane and the type of chemicals it comes into contact with. It is important to consult the manufacturer's specifications and recommendations to ensure the membrane is suitable for the intended chemical exposure.

- Q: Can a waterproofing membrane be used in balconies or decks?

- Yes, a waterproofing membrane can be used in balconies or decks to protect the underlying structure from water damage and ensure a longer lifespan for the outdoor space.

- Q: Can a waterproofing membrane be used for a water tank liner?

- Yes, a waterproofing membrane can be used as a water tank liner. Waterproofing membranes are designed to prevent water from penetrating through surfaces, making them an effective choice for lining water tanks and preventing leaks.

- Q: Are there any specific building code requirements for waterproofing membranes?

- Waterproofing membranes are subject to specific building code requirements. These requirements vary depending on the jurisdiction, but most codes mandate that waterproofing membranes meet certain standards and specifications. The purpose of these requirements is to protect buildings from water damage and maintain the safety and integrity of the structure. Some typical building code requirements for waterproofing membranes include: 1. Material standards: The building code may stipulate the type of materials that are permissible for waterproofing membranes. This can include specifications for the membrane's type, such as liquid-applied or sheet membranes, as well as requirements for thickness and composition. 2. Installation standards: The building code may provide specific instructions and techniques for installing waterproofing membranes. This can include requirements for appropriate surface preparation, application procedures, and details concerning penetrations and transitions. 3. Testing and certification: Building codes may mandate that waterproofing membranes undergo certain tests and meet specific performance criteria. This can include tests for water penetration resistance, durability, and compatibility with other building materials. In some cases, the code may require certification from a recognized testing laboratory. 4. Code compliance documentation: Building codes often demand that waterproofing membranes be installed in accordance with approved plans and specifications. This means that contractors may need to submit documentation to demonstrate compliance with the code, such as product data sheets, manufacturer's installation instructions, and details of the proposed waterproofing system. It is crucial to consult the local building code or regulatory authority to ascertain the specific requirements for waterproofing membranes in a particular jurisdiction. Complying with these requirements is vital to ensure the proper functioning and longevity of the waterproofing system and to prevent issues like water intrusion, mold growth, and structural damage.

- Q: How to distinguish whether the waterproofing membrane is polyester tires?

- Polyester tires (polyester fabric, polyester felt, polyester linoleum fabric) with high strength, high extension and puncture resistance, light weight, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion. Technical requirements, including the appearance of quality, intrinsic quality assessment projects and internal quality reference project, the indicators are in line with the provisions of the waterproof standards. Routine project tests should be in accordance with national standards test methods, thermal stability, bending, impregnation, water resistance test methods have done a detailed test.

Send your message to us

PVC Root Puncture Resistant Waterproof Membrane with Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords